15

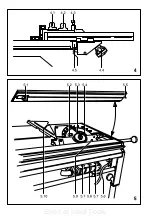

9.5 Moving the mitre fence

According to regulations, a higher or a lower

workpiece guide face must be available as a stop

depending on the workpiece.

Release the rotary knob (4.1) to remove the guide

ruler and replace in the guide groove after rotating

by 90° (fig. 4). The aluminium section has been

dimensioned so that both a high guide face and

the lower guide face required for flatter

workpieces is available.

9.6 Fence ruler

The fence ruleris set off on one side by 8 mm.

The cross fence can be moved up to the saw cut to

support the workpiece with this guide rail without

the upper protective hood having to be removed.

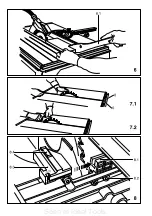

9.7 Linear stop

The fence ruler is set parallel to the saw cut for line-

ar cuts. Use the slide stick (6.1) to push through

narrow workpieces.

To enable the fence to be aligned according to the

scale on the front edge of the table, the zeroes of

the two scales on the left and right are set to the left

and right cutting edge of the saw blade in the works

(7.1).

10 Dust extraction

The PRECISIO has a fitted dust extractor set (Or-

der No. 488 292; included with the CS 70 EB) and

has been tested in accordance with EN 1093-8.

A wood dust concentration of 2 mg/m

3

is reliably

maintained in the proximity of the tool provided a

dust extractor with the following features is

connected:

dust extractor in accordance with EN 60335-2-

69, dust class M;

connection adapter Ø 50 mm;

volume flow of at least 142 m

3

/h;

vacuum approx. 3,000 Pa.

Note:

The Festool dust extractors CTM 22 E

CTM 55 E meet these requirements.

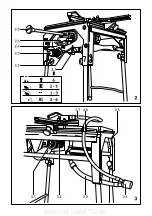

10.1 Fitting the dust extractor set

Connect suction hose Ø 27 mm (3.7) to the upper

protective hood. Plug the hose holder (3.6) into

the clamping rail of the saw table to guide the

suction hose.

Connect suction hose Ø 36 mm (3.3) to the lower

protective hood.

Join both suction hoses with a Y-piece (3.4) and

connect to a dust extractor with a Ø 50 mm

connection.

10.2 General remarks

If dust chips block the suction channel of the lower

protective hood, open the flap (5.6) by a gap of

approx. 8 mm by releasing the rotary knob (5.8)

and remove the blockage.

In the event of serious blockages, or if saw sections

jam, the seals (5.7) can be released with the

enclosed hexagon key so that the flap (5.6) can be

fully opened.

The hexagon key is fastened on the saw blade cover

directly above the flap (5.6).

Attention:

disconnect the plug from the mains

before unscrewing the seals.

Once the blockage has been removed reclose the

flap with the seals.

11 Concealed cuts

As already described in section 4, the height of the

riving knife can be locked in two positions without

tools.

Remove the upper protective cover for concealed

cuts and bring the riving knife into its lower locked

position by pressing down firmly (7.1).

When carrying out concealed cuts make sure of a

good workpiece guidance by pressing the

workpiece firmly onto the table.

Select the sequence of cuts so that sides of the

workpiece which have already been cut are not on

the side facing the fence.

Return the riving knife into its upper position (7.2)

and replace the protective cover on completion of

any concealed cuts.

12 Changing the saw blade

Unplug from the mains before changing the saw

blade.

Only use saw blades with the following dimensions:

Outer diameter

220 - 226 mm

Bore diameter

30 mm

Core thickness of blade

1.8 mm

Width of cut

2-2.5 mm

Lock the saw in its foremost position (setting up

position) and set to maximum slant and depth of

cut.

Release insert clamp with rotary knob (5.1), push

claw forwards.

Raise rear of table inlay (1.4) from below and

remove from table from the front.

Remove the protective hood and swing the cover

(5.10) back.

Remove hexagon key (5.3) from holder and insert

into saw blade locking screw.

Seen at Ideal Tools.

Summary of Contents for Precisio CS 70 E

Page 2: ...Seen at Ideal Tools ...

Page 3: ...Seen at Ideal Tools ...

Page 4: ...Seen at Ideal Tools ...

Page 5: ...Seen at Ideal Tools ...