8

Mounting and installation

8.1 Installing the angle seat valve

Prerequisites

– The piping system is unpressurised and no medium flows in it

– Lines are clean

– The line ends are mounted

Clean valve

Remove all transport packaging. The material used in the packaging has been

specifically chosen for its recyclability (exception: oil-impregnated paper =

residual waste).

Traces of residual grease may be evident on the product due to the production

process used.

Clean the valve immediately before installation.

Warning

Risk of injury due to slipping or falling objects!

The angle seat valve can weigh up to 11.5 kg, depending on the product version.

Body parts can be crushed. In overhead installations, the result can be serious

head injuries.

Angle seat valve with appropriate means of securing against falling or

slipping.

1. Bring the angle seat valve into the mounting position.

– Observe the flow direction. The permitted direction of flow is marked by an

arrow on the valve housing.

2. Connect the piping on the valve housing.

– Max. tightening torque

è

3. Connect the line of the operating medium.

– Pneumatic connection (2): operating medium

– Pneumatic connection (4): exhaust port

4. For single-acting actuators: mount the silencer in the exhaust port or use

a tubing connection for guided exhaust air.

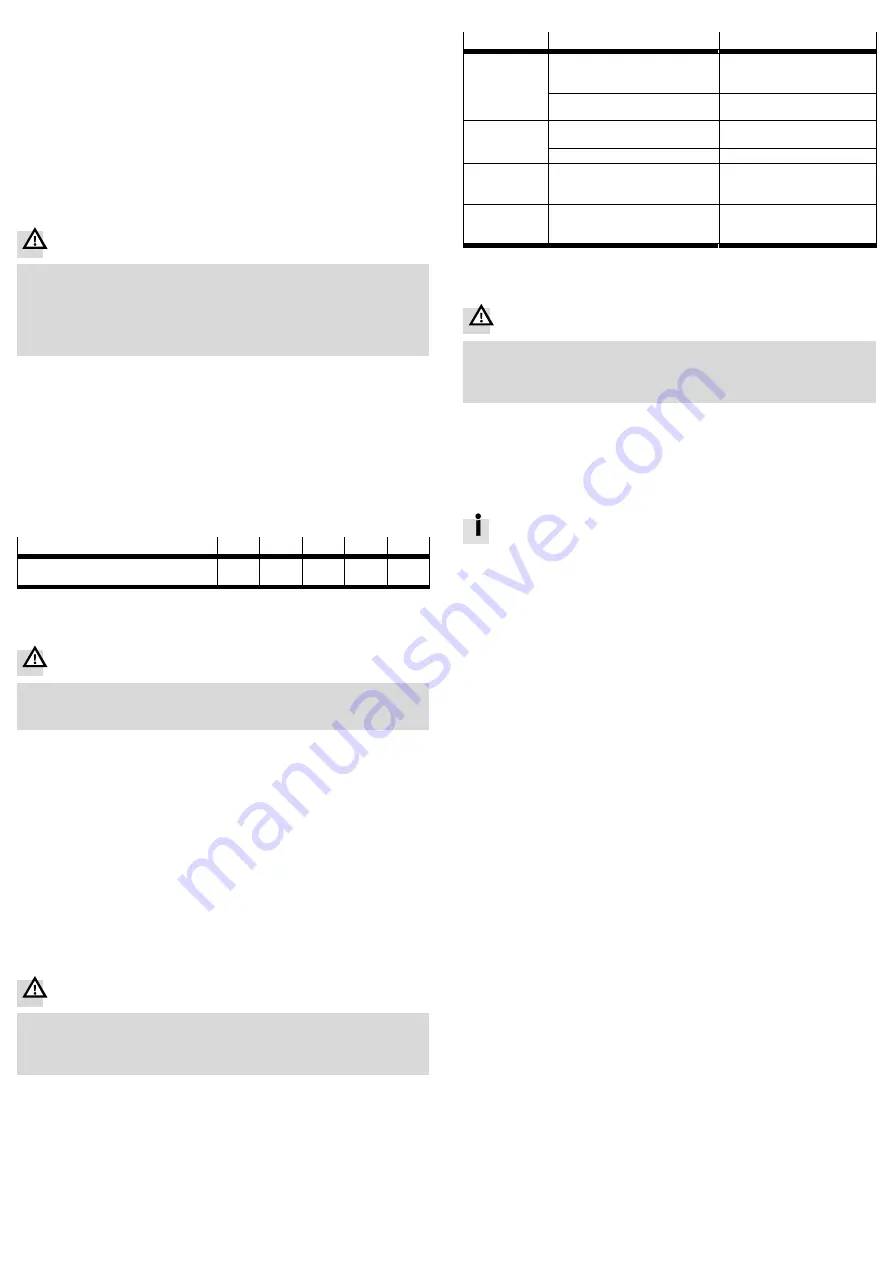

Connection size

[”]

1

1¼

1½

2

2½

Max. tightening torque

pipe connection

[Nm]

350

450

540

620

750

Fig. 7

9

Commissioning

Warning

Risk of injury from manipulation in the area of the angle seat valve!

Limbs can be cut or severed.

Place only the fully mounted angle seat valve in operation.

Prerequisites

– The valve is fully mounted and connected

Checking operating conditions

Observe operating conditions and limits

è

Technical data and product labelling.

Check connection points for tightness.

Check compatibility of the devices in the system for maximum pressure

(consider pressure peaks). If necessary, adjust the application parameters.

Placing valve in operation

1. Supply medium.

2. Slowly apply operating pressure to the valve. The operating pressure required

for reliable switching of the valve depends on the medium pressure

è

3. Function and direction control of the individual pneumatic actuators.

10

Operation

Danger

Risk of injury from touching hot surfaces!

Valve and actuator can become hot at high temperature of medium. Severe

burns are possible.

Do not touch the angle seat valve during operation or immediately afterward.

Comply with operating conditions.

Comply with maintenance conditions

è

Chap. 12.

After longer idle times:

Actuate the valve several times and check for correct function.

11

Malfunctions

Malfunction

Possible cause

Remedy

Valve does not

close or closes

too slowly

VZXA-B: medium pressure is too high

or operating pressure too low

Creating necessary differential

pressure

è

Adjust operating pressure.

Too many contaminants, or contamin

ants that are too large, in the medium

Comply with operating condi

tions.

Valve does not

open or opens

too slowly

VZXA-A: operating pressure is too low

or medium pressure too high

Adjust operating pressure or

medium pressure.

VZXA-B: operating pressure too low

Adjust operating pressure.

Medium leaking

from a leakage

hole

Seal cartridge defective

Replace seal cartridge

è

Spare parts documentation.

Medium will not

let itself be

shut off

Seat seal defective

Replace seat seal

è

Spare parts documentation.

Fig. 8

12

Maintenance

Danger

Risk of injury from touching hot surfaces!

Valve and actuator can become hot at high temperature of medium. Severe

burns are possible.

Allow the angle seat valve to cool off before working on it.

Check product regularly from the outside for leakage.

Check function of the product regularly.

Clean product regularly with commercial cleaners.

12.1 Proof Test

The proof test consists of turning the operating pressure off and back on.

Perform the proof test annually.

During the proof test, the safety of the application must be ensured.

1. Switch off the operating pressure.

2. Check valve position.

è

The test is successful if the safe status is reached within the specified time.

For evaluation of the safe status

è

3. Slowly apply operating pressure to the valve.

è

The test is successful if the valve takes its original position again.

4. Check the valve externally (visual inspection).

è

The test is successful if no defect or leakage is detected.

5. Document test results.