4.2

Product design

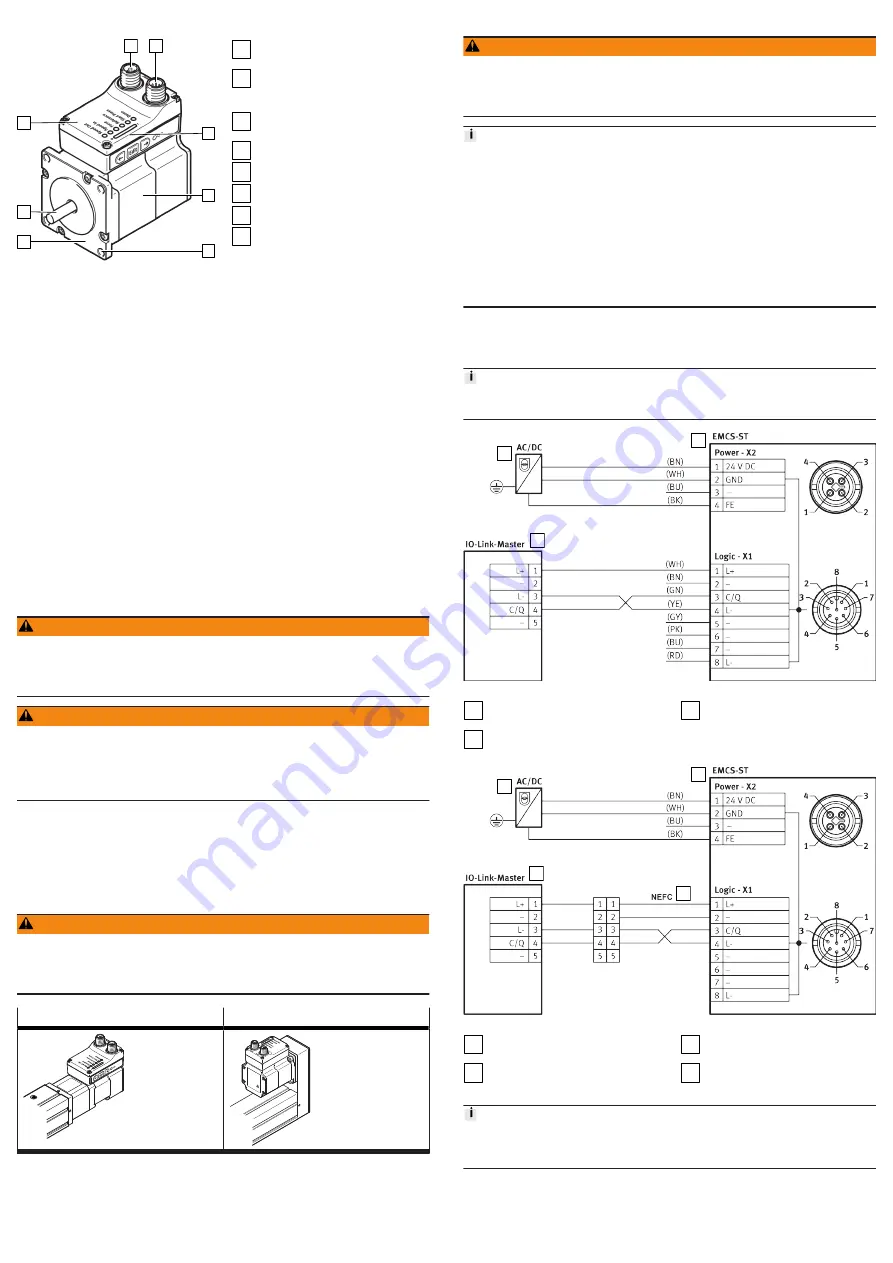

1

2

3

4

5

6

7

8

Fig. 2: Product design EMCS-ST

(example EMCS-ST-57 -...)

1

Connection for load voltage

supply [Power]

2

Connection of logic power supply

and digital inputs/outputs (DIO)

or IO-Link (LK) [Logic]

3

Display and operating compo-

nents (HMI)

4

Stepper motor

5

Mounting holes

6

Motor flange

7

Motor shaft

8

Controller housing

5

Transport

Transport and storage conditions

–

Store and transport the product in its original packaging.

–

Store product in a cool, dry, shaded and corrosion protected environment.

–

Store product in areas where it is not exposed to oils, greases and degreasing

vapours.

–

Keep storage times short.

6

Replacement

Replace integrated drive EMCS

1. Save the application parameters to the IO-Link master

2. Remove the defective integrated drive EMCS

3. Mount the new integrated drive EMCS

4. Connect the integrated drive EMCS

5. Commission the drive system

6. Update the parameter set

7. Update the firmware (optional)

è

"Integrated drive EMCS" instruction

manual

7

Disassembly

WARNING

Unexpected movement of components.

Injury due to impacts or crushing.

• Before working on the product, switch off the control and secure it to prevent it

from being switched back on accidentally.

WARNING

Risk of Injury due to Unexpected Movement of Components

For vertical or slanted mounting position: when power is off, moving parts can

travel or fall uncontrolled into the lower end position.

• Bring moving parts of the product into a safe end position or secure them

against falling.

Dismantling the integrated drive EMCS

1. Allow the product to cool down to room temperature.

2. Disconnect electrical installations on the EMCS.

3. Remove EMCS from the mounting kit

4. Observe transport information

8

Assembly

WARNING

Risk of injury due to unexpected movement of components.

The drive can move freely in the voltage-free state. This can cause unexpected

movements of the connected mechanics and crush parts of the body.

• Bring moving parts of the mechanical system into a safe position.

Axial kit EAMM-A

Parallel kit EAMM-U

Tab. 4: Overview of motor mountings (example electric cylinder unit EPCS-BS)

Only loosen screws or threaded pins that are described in the directions in the

instruction manuals.

1. Fasten motor mounting kit, observe instruction manual

2. Fasten the motor without tension.

Connect motor cables only on completion of mounting.

9

Installation

WARNING

Risk of injury due to electric shock.

• For the electrical power supply with extra-low voltages, use only PELV circuits

that guarantee a reinforced isolation from the mains network.

• Observe IEC 60204-1/EN 60204-1.

Damage to the device due to non-approved potentials at the pins

• Power connection:

• Do not connect pin 3

• Logic connection:

• Only after connection of the reference potentials GND/L– [Pin 4/8] can 24V

levels be applied to digital outputs DO1/DO2 [Pin 2/3] or the IO-Link

communication signal C/Q [Pin 3].

• The digital outputs DO1/DO2 [Pin 2/3] and the IO-Link communication

signal C/Q [Pin 3] must be disconnected 100 ms before the power

supply connections GND/L– [Pin 4/8] and 24 V DC/L + [Pin 1], e.g. by

the interposition of relay contacts.

•

Connect the cables to the [Logic] and [Power] connections of the integrated

drive EMCS-ST.

Wiring diagram: IO-Link operation, port class A (with and without NEFC adapter)

Current consumption of IO-Link power supply [Logic]

An input current at pin 1 (L+) of 100 ... 150 mA is required for operation.

1

2

3

Fig. 3: Wiring diagram: IO-Link operation

1

PELV fixed power supply for the

load voltage supply

2

Integrated drive EMCS-ST

3

IO-Link master with IO-Link inter-

face

1

2

3

4

Fig. 4: Wiring diagram: IO-Link operation with adapter

1

PELV fixed power supply for load

voltage supply

2

Integrated drive EMCS-ST

3

IO-Link master with IO-Link inter-

face

4

Adapter NEFC

Core colours of Festo cables:

BK = black, BN = brown, BU = blue, GN = green, GY = grey, PK = pink,

WH = white, YE = yellow

Connection [Logic]: IO-Link (LK), port class A

IO-Link data is exchanged with the IO-Link master via the [Logic] connection and

the logic part of the device is supplied with electrical voltage.