9.2

Procedure

WARNING

Danger of crushing.

The gripper fingers could move unintentionally and crush body parts.

• Do not reach into the movement range.

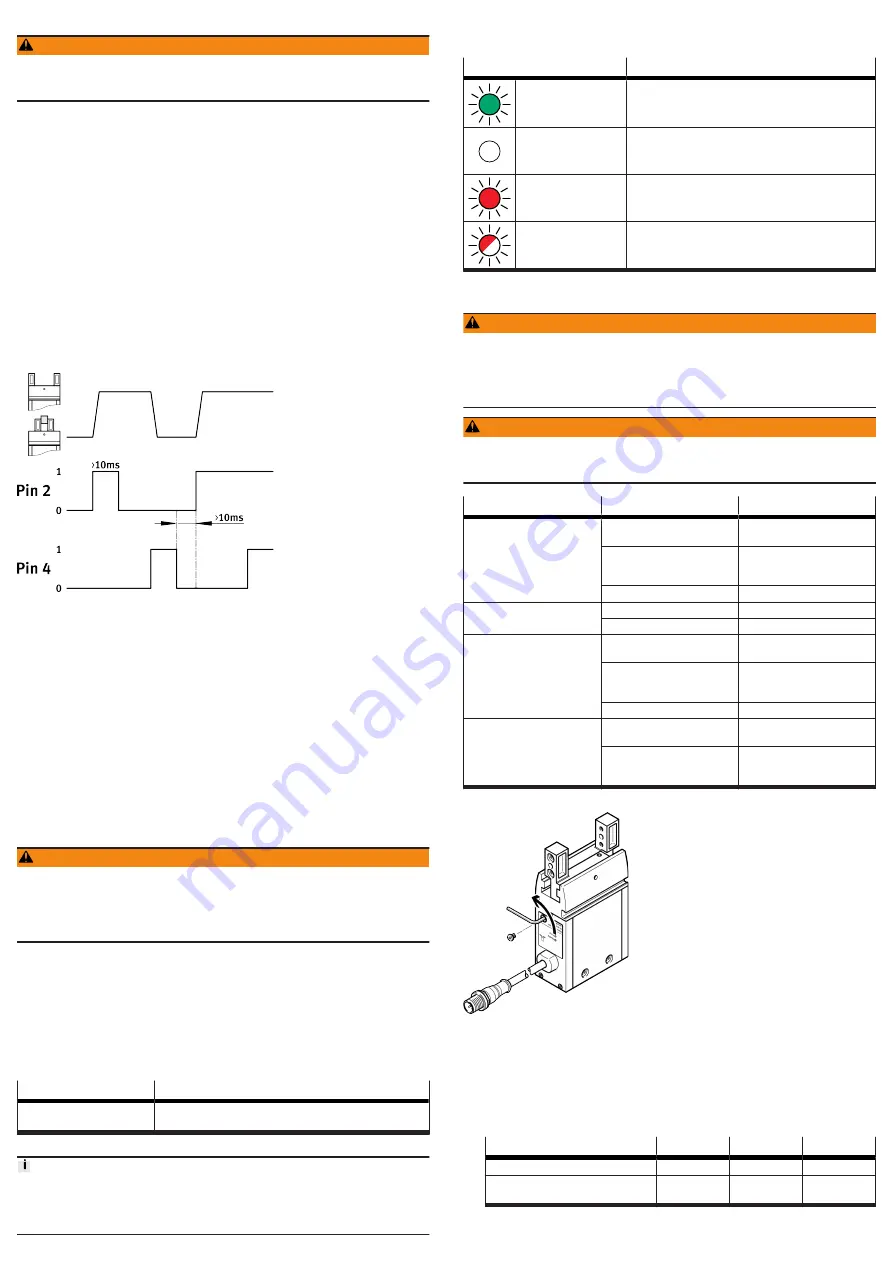

The gripper is controlled (open/close) by commands from a higher-order con-

troller to the digital inputs (Pin 2 and Pin 4). In this case, the gripper is edge-trig-

gered and moves on detection of a rising edge. As soon as a high signal level

is detected, travel to the stop is executed. Please ensure that, once travel is

complete, the corresponding signal is reset again before transmitting a signal in

the opposite direction. Pause times of at least 10 ms must be observed between

cancelling the signal and the next command.

If a signal remains at the high signal level until the next travel, this can prevent

unintended travel being initiated in the event of a cable break.

For certain gripping situations, it may be necessary to send an additional gripping

signal (max. 3x in one direction).

Behaviour in emergency off

–

In the event of an emergency off, the gripper jaws stop moving.

–

When the gripper grips a component, the position and force achieved are

maintained by the self-locking function of the jaws.

–

If the gripper jaws are in motion at the time the current is switched off, the

gripping process is no longer fully completed. A force cannot or can only be

partially dynamically applied.

Fig. 7: Signal diagram

1. Switch on the power supply.

Ä

The Ready LED is green.

2. Open gripper jaws:

–

Apply a rising edge (0

è

1) at pin 2

–

Logic 0 at pin 4.

Pin allocation for connection

3. Approach the workpiece to be gripped.

4. Closing the gripper jaws:

–

Apply a rising edge (0

è

1) at pin 4

–

Logic 0 at pin 2.

5. Execute a test run. During the test, check that the workpiece is gripped

properly.

10

Maintenance

10.1

Safety

WARNING

Danger of crushing due to unexpectedly fast-moving loads and unintentional

movements.

• Remove the payload.

• Switch off power to the product.

• Safeguard the power supply from being switched on again unintentionally.

10.2

Cleaning

Clean the product with a soft cloth. Do not use aggressive cleaning agents.

For use with reduced particle emission:

–

Remove abrasion and contamination from the product on the following

schedule:

–

Prior to initial commissioning.

–

Regularly during operation.

10.3

Lubrication

Interval

Maintenance work

After 5 million switching cycles

Grease the guide of the gripper jaws. Permissible lubricating

grease

Tab. 4

Cut the lubrication interval by half if one of the following applies:

• High thermal stress

• Heavy contamination

• Proximity of grease-dissolving liquids or vapours

11

Malfunctions

11.1

Diagnostics

LED

Meaning

Ready LED is green

Nominal operating voltage at connection

3

pin 1 is

24 V DC ± 10%.

Ready LED is off

Nominal operating voltage is switched off.

Error LED is red

Nominal operating voltage at connection

3

Pin 1 is outside

the valid range.

Error LED flashes red

Device error

Tab. 5: LED

11.2

Fault clearance

WARNING

Danger of crushing due to unexpectedly fast-moving loads and unintentional

movements.

• Remove the payload.

• Switch off power to the product.

• Safeguard the power supply from being switched on again unintentionally.

WARNING

Danger of crushing.

The gripper fingers could move unintentionally and crush body parts.

• Do not reach into the movement range.

Fault description

Cause

Remedy

Gripper does not hold payload

securely.

Gripping point of gripper fin-

gers is too far outwards.

Move gripping point inwards.

Sufficient force cannot be

applied.

Increase travel path. Minimum

travel

Payload is too heavy.

Select a larger gripper.

Gripper fingers do not move

uniformly.

Slots are dirty.

Clean and grease the slots.

Gripper jaws are distorted.

Rectify distortion.

Gripper fingers do not open/

close.

Jamming due to excessive

speed of the gripper fingers.

Resolve jamming

Interruption of communication

between gripper and control

unit.

Check connecting cable.

Gripper is faulty.

Replace gripper.

Squeaking noises

Lack of lubrication

Lubricate gripper

Payload is too great.

Observe permissible values

Tab. 6: Fault clearance

Fig. 8: Resolve jamming of gripper jaws

1. Remove the plug screw.

2. Rotate the worm shaft underneath using the hex wrench until the jamming is

resolved:

–

Anti-clockwise (external gripping)

–

Clockwise (internal gripping)

3. Retighten plug screw.

EHPS

-16

-20

-25

Hex wrench

ß

1.5

ß

1.5

ß

2

Tightening torque for plug

screw

[Nm]

0.6

0.6

2.8