‘ResetDirectionFlag’ (bit 50)

The gripper stores the last travelled direction. After the ‘Close’ command, the

‘Open’ command must follow and vice versa. If, for example, it is necessary to

move the jaws in the same direction when changing a workpiece, the direction

flag ‘DirectionOpenFlag’ or ‘DirectionCloseFlag’ can be reset via the ‘ResetDirec-

tionFlag’ command. Then a movement in the previous direction is possible again.

‘TeachGrippingPosition’ (bit 51)

–

‘WorkpieceNo = 0’

This command is not possible for the ‘WorkpieceSet= 0’.

–

‘WorkpieceNo

>

0’

The stored parameter‘GrippingPosition’ in the ‘WorkpieceSet’ can be written

by this command. The ‘ActualPosition’ value on execution of ‘TeachGrippingPo-

sition’ is transferred to the ‘GrippingPosition’ parameter of the selected ‘Work-

pieceSet’.

Reaching of this gripping position can be checked in the ‘StatusWord’ with the

‘GrippedPositionFlag’ marker.

‘FindNewEndPositions’ (bit 55)

If required (for example in the case of reduced installation space), the end posi-

tions can be redefined with this command so that the desired layers are returned

with the ‘ClosedPositionFlag’ and ‘OpenedPositionFlag’ flags in the ‘StatusWord’.

This command ‘FindNewEndPositions’ moves the gripper open-close and open

again. From the open position, the gripper moves exclusively closed-open. The

minimum and maximum values approached in this way are transferred to the

internal memory as new end positions.

The positions are reset by executing the command again, whereby the gripper can

again move its maximum stroke without a previous stop.

‘Open’ (bit 56)

With this command, the gripper moves the jaws to the outer position (opening).

‘Close’ (bit 57)

With this command, the gripper moves the jaws to the inner position (closing).

‘ResetError’ (bit 63)

With this command, safety-relevant errors can be acknowledged and the gripper

can be switched back to operational status.

Individual errors cannot be reset by the user. The reset is performed automatically

as soon as the specified operating conditions are met again.

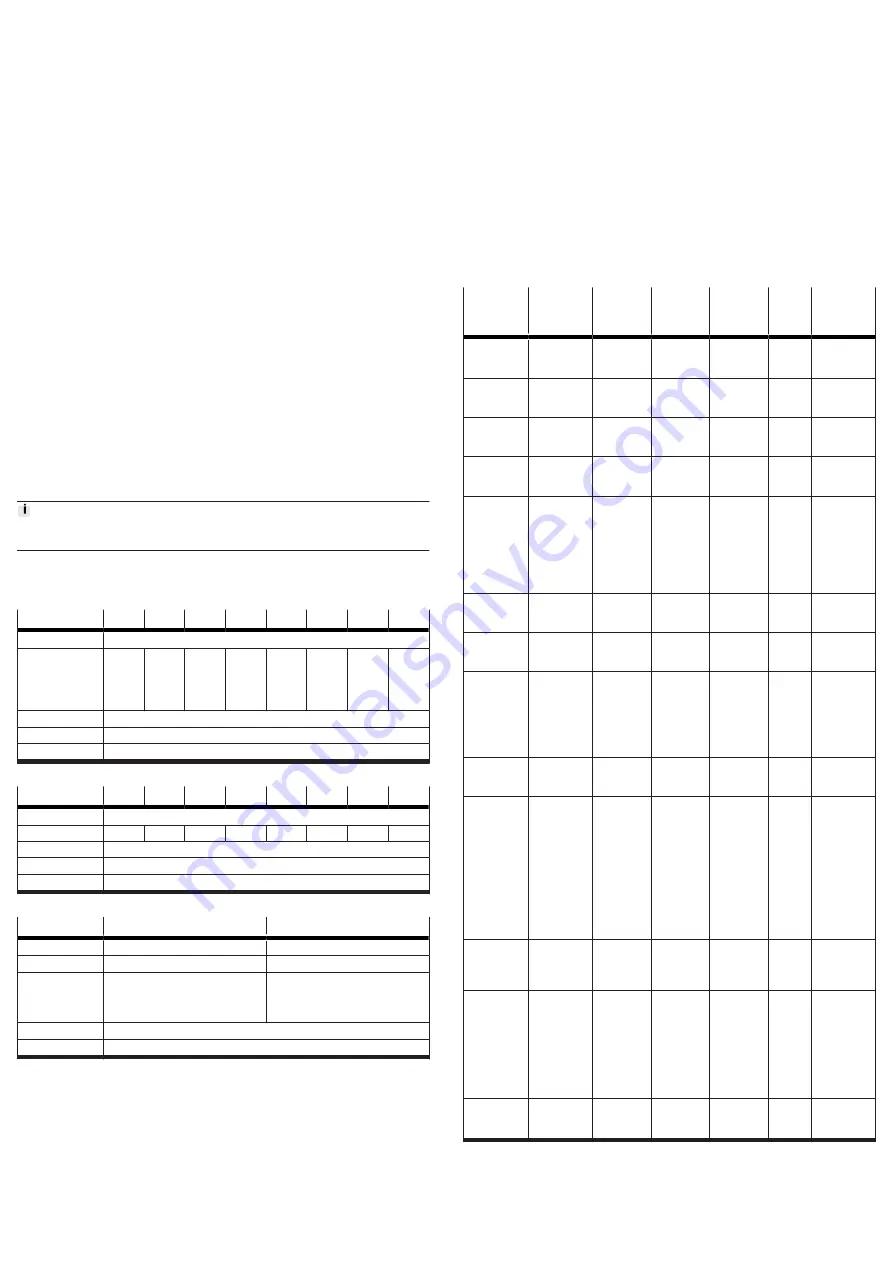

10.7

Process Data IN

The gripper transmits data cyclically. This allows the gripping process to be moni-

tored.

Bit

47

46

45

44

43

42

41

40

Process data

‘StatusWord’

Data content

‘Error’

‘Direc-

tionClo-

seFlag’

‘Direc-

tionO-

pen-

Flag’

‘Latch-

DataOk

’

‘Unde-

fined-

Posi-

tionFla

g’

‘Close-

dPosi-

tion-

Flag’

‘Grip-

pedPo-

sition-

Flag’

‘Open-

edPosi-

tion-

Flag’

Value range

0 … 65535

Index

0x0028

Data type

UIntegerT16

Tab. 12: Process data IN

Bit

39

38

37

36

35

34

33

32

Process data

‘StatusWord’

Data content

–

‘Ready’

–

–

–

–

–

–

Value range

0 … 65535

Index

0x0028

Data type

UIntegerT16

Tab. 13: Process data IN

Bit

31 … 16

15 … 0

Meaning

MSB … LSB

MSB … LSB

Process data

‘ErrorNumber’

‘ActualPosition’

Value range

0 … 65535

0 … max. jaw stroke

–

EHPS-16: 0 … 2150

–

EHPS-20: 0 … 2750

–

EHPS-25: 0 … 3350

Index

0x0028

Data type

UIntegerT16

Tab. 14: Process data IN

10.7.1

Description ‘StatusWord’

‘Ready’ (bit 38)

Active as soon as the gripper is raised. It can also be used to check a byte swap.

‘OpenedPositionFlag’ (bit 40)

Active when the open position is reached. In the case of a previous redefinition of

the end position, the bit always becomes active when the gripper has reached this

stored position or is further opened.

‘GrippedPositionFlag’ (bit 41)

Active, if the gripper is in the taught-in or predefined gripper position, taking into

account the predefined tolerances.

‘ClosedPositionFlag’ (bit 42)

Active when the gripper has reached the closed position. In the case of a previous

redefinition of the end position, the bit always becomes active when the gripper

has reached this stored position or is further closed.

‘UndefinedPositionFlag’ (bit 43)

Active if the gripper is in an undefined position.

‘LatchDataOk’ (bit 44)

Active as soon as the transmitted data has been transferred from the gripper.

‘DirectionOpenFlag’ (bit 45)

This bit is a direction flag and becomes active if the last run command was from

the ‘Open’ master.

‘DirectionCloseFlag’ (bit 46)

This bit is a direction flag and becomes active if the last run command was from

the ‘Close’ master.

‘Error’ (bit 47)

Active if there is an error. The present errors can be viewed in the ‘ErrorNumber’

and ‘ErrorMessage’ parameters.

10.8

Device-specific parameters

Index

Subindex

Name

Descrip-

tion

Value

(example

)

Lengt

h

[byte]

Format

0x0018

‘Applica-

tionSpeci-

ficTag’

Text to be

defined by

the user

***

32

StringT

0x0040

‘Status-

Word’

1)

0x0041

‘Error-

Number’

1)

0x0042

‘Cycle-

Counter’

Counter for

gripping

cycles

0 … 429496

7295

4

UIntegerT32

0x0043

‘Tempera-

ture’

Gripper

tempera-

ture in °C

If the

gripper

<

tempera-

ture is 0 °C,

0 is output.

0 … 65535

2

UIntegerT16

0x0044

‘Control-

Word’

1)

0x0045

‘ErrorMes-

sage’

Outputs an

error

description.

64

StringT

0x0046

‘ErrorCount’ Counter of

error mes-

sages

2

UIntegerT16

0x0100

‘ActualPosi-

tion’

1)

0x0101

‘Gripping-

Position’

2)

Gripper

position

e.g. for

checking

the work-

piece

dimensions

0 … nominal

stroke (+tol-

erance)

–

EHPS-16:

0 … 215

0

–

EHPS-20:

0 … 275

0

–

EHPS-25:

0 … 335

0

2

UIntegerT16

0x0102

‘Workpie-

ceNo’

1)

Workpiece

number of a

workpiece

set

0 … 32

1

UIntegerT8

0x0103

‘Gripping-

Mode’

2)

Driving

mode

–

Invalid: 0

–

Universal:

100

–

External

gripping:

60

–

Internal

gripping:

70

1

UIntegerT8

0x0104

‘Gripping-

Tolerance’

2)

Tolerance of

‘Gripping-

Position’

0 … 255

1

UIntegerT8