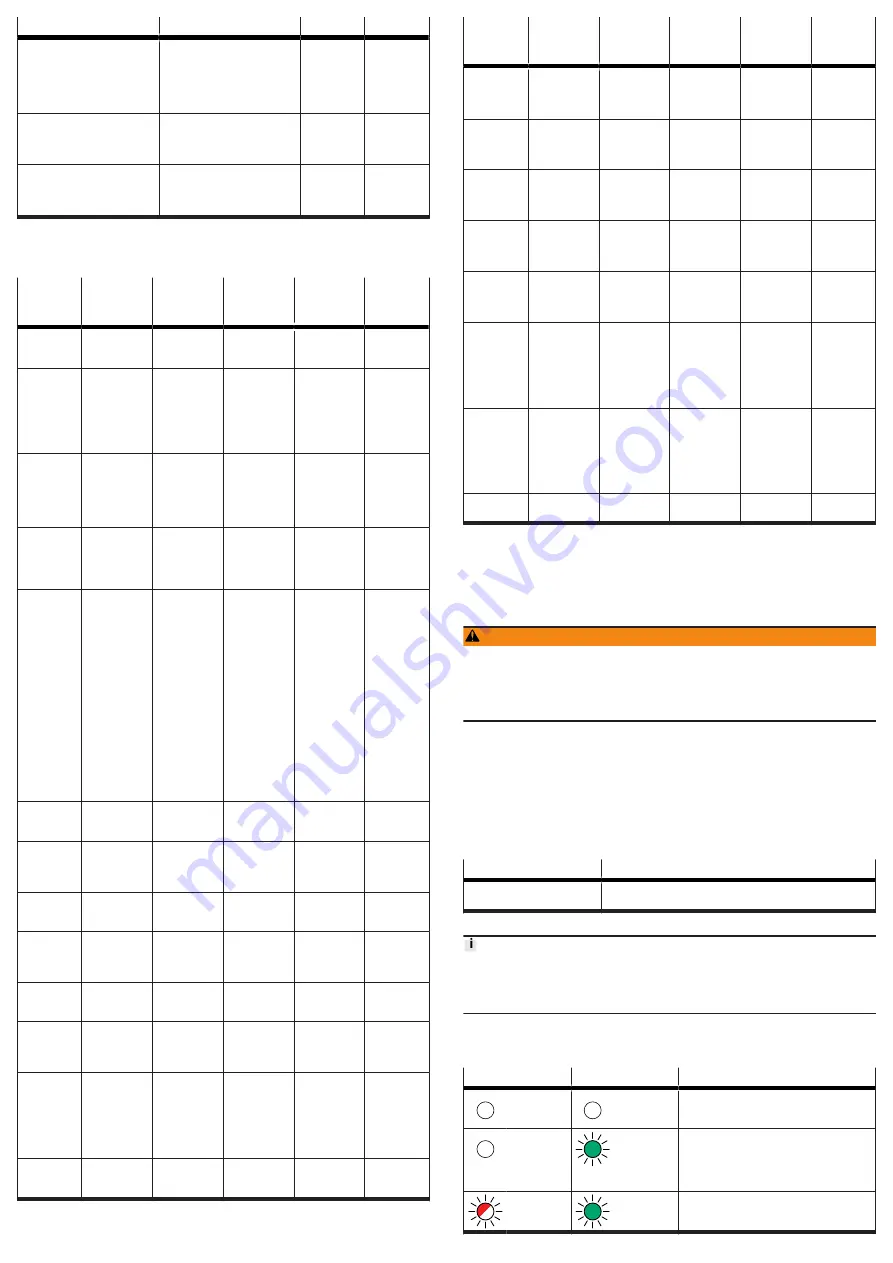

Name

Description

Index

Value

[Enable Gripper]

Activation of system commands

for easy triggering of movement

commands. A standard configu-

ration is thus loaded into the

parameters and the movement

commands are released.

0x0002

160

[Close Gripper]

With previous release, this com-

mand can initiate a movement of

the gripper jaws in the direction

of "closing".

0x0002

161

[Open Gripper]

With previous release, this com-

mand can initiate a movement of

the gripper jaws in the direction

of "opening".

0x0002

162

Tab. 23: System Commands

10.12

Fault clearance IO-Link

Parameter ‘ErrorNumber’

Diagnostic

message

Hex (Dec)

Device

status

Error

Possible

cause

Remedy

‘Error-

Count’

1)

0x0 (0)

‘Status ok,

device is

ready’

No

0x100 (256)

Outside the

specification

‘Power supply

error’

–

Actuator

supply not

connected

–

Cable break

–

Actuator

supply not

sufficient

Testing the

actuator

supply voltage

Yes

0x101 (257)

Outside of

specification

(drive can no

longer be

moved)

‘Temperature

too high’

–

Ambient

tempera-

ture too

high

–

Gripper has

overload

Ensure ade-

quate pressuri-

sation/

cooling/

connection

Yes

0x102 (258)

Outside of

specification

(drive can no

longer be

moved)

‘Temperature

too low’

Ambient tem-

perature too

low

Ensure suffi-

cient operating

temperature

Yes

0x010A

(266)

)

Outside the

specification

‘Actuator

under voltage

during move-

ment’

–

Actuator

supply

unstable

–

Line resist-

ance

increased

(faulty

supply

cable)

–

Power

supply not

sufficiently

designed

for peak

loads,

faulty

supply

cables

–

Check grip-

ping force,

check

power

supply and

peak load

–

Manual

acknowl-

edgement

of error

message

necessary

No

0x300 (768)

Outside the

specification

‘ControlWord

not plausible’

Incorrect value

in ‘Control-

Word’

Checking the

value in the

‘ControlWord’

No

0x301 (769)

Outside the

specification

‘GrippingPosi-

tion not plau-

sible’

Incorrect value

in parameter

‘GrippingPosi-

tion’

Check the

parameter

‘GrippingPosi-

tion’

No

0x302 (770)

Outside the

specification

‘GrippingForce

not plausible’

Incorrect value

in parameter

‘GrippingForce’

Check the

parameter

‘GrippingForce’

No

0x304 (772)

Outside the

specification

‘GrippingToler-

ance not plau-

sible’

Incorrect value

in parameter

‘GrippingToler-

ance’

Check the

parameter

‘GrippingToler-

ance’

No

0x305 (773)

2)

Failure

‘Reference

position error’

Gripper has no

reference posi-

tion

Service Festo

SE & Co. KG

Yes

0x306 (774)

Outside the

specification

‘GrippingMode

not plausible’

Incorrect value

in parameter

‘Gripping-

Mode’

Check the

parameter

‘Gripping-

Mode’

No

0x307 (775)

Motion task

cannot be exe-

cuted

‘Drive com-

mand cannot

be executed’

Multiple travel

commands in

the same

direction

Reset ‘Reset-

DirectionFlag’

direction flag

or send move-

ment com-

mand in the

other direction

No

0x308 (776)

Outside the

specification

‘WorkpieceNo

not plausible’

Incorrect value

in parameter

‘WorkpieceNo’

Check the

parameter

‘WorkpieceNo’

No

Diagnostic

message

Hex (Dec)

Device

status

Error

Possible

cause

Remedy

‘Error-

Count’

1)

0x309 (777)

Outside the

specification

‘GrippingPosi-

tion not

latched’

Process data

sent by the

master have

been changed

Transfer of the

changed

parameters by

‘LatchData.’

No

0x30D (781)

Outside the

specification

‘GrippingForce

not latched’

Process data

sent by the

master have

been changed

Transfer of the

changed

parameters by

‘LatchData.’

No

0x30F (783)

Outside the

specification

‘GrippingToler-

ance not

latched’

Process data

sent by the

master have

been changed

Transfer of the

changed

parameters by

‘LatchData.’

No

0x310 (784)

Outside the

specification

‘GrippingMode

not latched’

Process data

sent by the

master have

been changed

Transfer of the

changed

parameters by

‘LatchData.’

No

0x311 (785)

Outside the

specification

‘WorkpieceNo

not latched’

Process data

sent by the

master have

been changed

Transfer of the

changed

parameters by

‘LatchData.’

No

0x312 (786)

Outside the

specification

‘Initial hand-

shake missing’

After a cold

start, a single

data migration

by ‘LatchData’

(‘ControlWord’

= 1) is

required.

Transfer of the

changed

parameters by

‘LatchData.’

No

0x400

(1024)

3)

Failure

‘Gripper

blocked’

–

Gripper is

difficult to

move

–

The travel

path of the

grab is

impaired

–

Restore the

free move-

ment of the

gripper

–

Service

Festo

SE & Co. KG

Yes

0x406 (1030) Failure

‘System error /

internal error’

Internal

system error

Service Festo

SE & Co. KG

Yes

1) Incrementing the "ErrorCount" parameter for these messages

2) No homing required

3) Acknowledge error with "ResetError"

Tab. 24: "ErrorNumber" parameter

11

Maintenance

11.1

Safety

WARNING

Danger of crushing due to unexpectedly fast-moving loads and unintentional

movements.

• Remove the payload.

• Switch off power to the product.

• Safeguard the power supply from being switched on again unintentionally.

11.2

Cleaning

Clean the product with a soft cloth. Do not use aggressive cleaning agents.

For use with reduced particle emission:

–

Remove abrasion and contamination from the product on the following

schedule:

–

Prior to initial commissioning.

–

Regularly during operation.

11.3

Lubrication

Interval

Maintenance work

After 5 million switching cycles

Grease the guide of the gripper jaws. Permissible lubricating

grease

Tab. 25

Cut the lubrication interval by half if one of the following applies:

• High thermal stress

• Heavy contamination

• Proximity of grease-dissolving liquids or vapours

12

Malfunctions

12.1

Diagnostics

LED red ‘Error’

LED green ‘Ready’

Meaning

off

off

–

IO-Link Supply voltage is not connected

è

IO-LinkCommunication not active.

off

green light

Actuator ready for operation (Fallback, SIO

Mode)

–

IO-Link Supply voltage: connected

–

IO-Link Communication: not active

–

Actuator supply voltage: connected

flashing red

green light

–

IO-Link Supply voltage: connected

–

IO-Link Communication: not active

–

Actuator supply voltage: not connected