11.3 LED indicators

Various LED indicators are available on every module for the visualisation of the

statuses and errors. In the process, LED indicators specific to the system and

module or network are differentiated.

The system-specific LED indicators of the controllers and bus modules are

described in this document.

LED indicators specific to the module or network are described in the

documentation for the respective module.

Power System [PS] – Operating voltage supply U

EL/SEN

LED (green)

Significance

Remedy

Lights up

ON

OFF

Voltage supply present.

No error.

–

Flashes

ON

OFF

Voltage supply present, but

outside of the tolerance

range.

Eliminate undervoltage.

The link on the bus module

is missing or incomplete.

Check the link.

Flashes

ON

OFF

The internal fuse of the

voltage supply has

responded.

Eliminate short circuit/overload.

Depending on the parameterisa

tion, the voltage supply is then

switched on automatically again

(factory setting) or it must be

switched off and then on again.

Off

ON

OFF

Voltage supply not present.

Check connection of the power

supply.

Fig. 15

Power Load [PL] – Load voltage supply U

OUT

LED (green)

Significance

Remedy

Lights up

ON

OFF

Voltage supply present.

No error.

–

Flashes

ON

OFF

Voltage supply present, but

outside of the tolerance

range.

Eliminate undervoltage.

Off

ON

OFF

Voltage supply not present.

Check connection of the power

supply.

Fig. 16

System Failure [SF] – System failure

LED (red)

1)

Significance

Remedy

Flashes

ON

OFF

Simple error/information

(error class 1)

è

Description of the CPX-E system

ON

OFF

Error

(Error class 2)

ON

OFF

Serious error

(Error class 3)

Off

ON

OFF

No error

–

1)

The LED indicator “System Failure” [SF] flashes depending on the error class.

Fig. 17

Modify [M] – Parameterisation modified or “Force” active.

LED (yellow)

Significance

Lights up

ON

OFF

System start with saved parameterisation and saved CPX

expansion set; parameters and CPX expansion are saved

remanently; external parameterisation is blocked

1)

Caution when replacing systems with saved parameterisation. In

the case of these systems, parameterisation is not carried out

automatically by the higher-order controller on replacement.

Before replacement, note required settings and restore them

after replacement, if required.

Flashes

ON

OFF

The Forcen function is enabled.

1)

Off

ON

OFF

System start with default parameterisation (factory setting) and

current CPX expansion set; external parameterisation is possible

(presetting).

1)

The indication of the “Forcen” function (LED flashing) has priority over indication of the setting for the

system start with the saved parameterisation and saved extension (LED lights up).

Fig. 18

12

Maintenance

Note

Accumulation of heat due to reduced air supply to electronics.

Keep the ventilation slots free and regularly remove contamination.

13

Conversion

13.1 Replacing the module

Note

When a bus module, controller or complete system is replaced, a different

parameterisation will result in deviating behaviour.

Before replacement, check which settings are required and restore them after

the replacement.

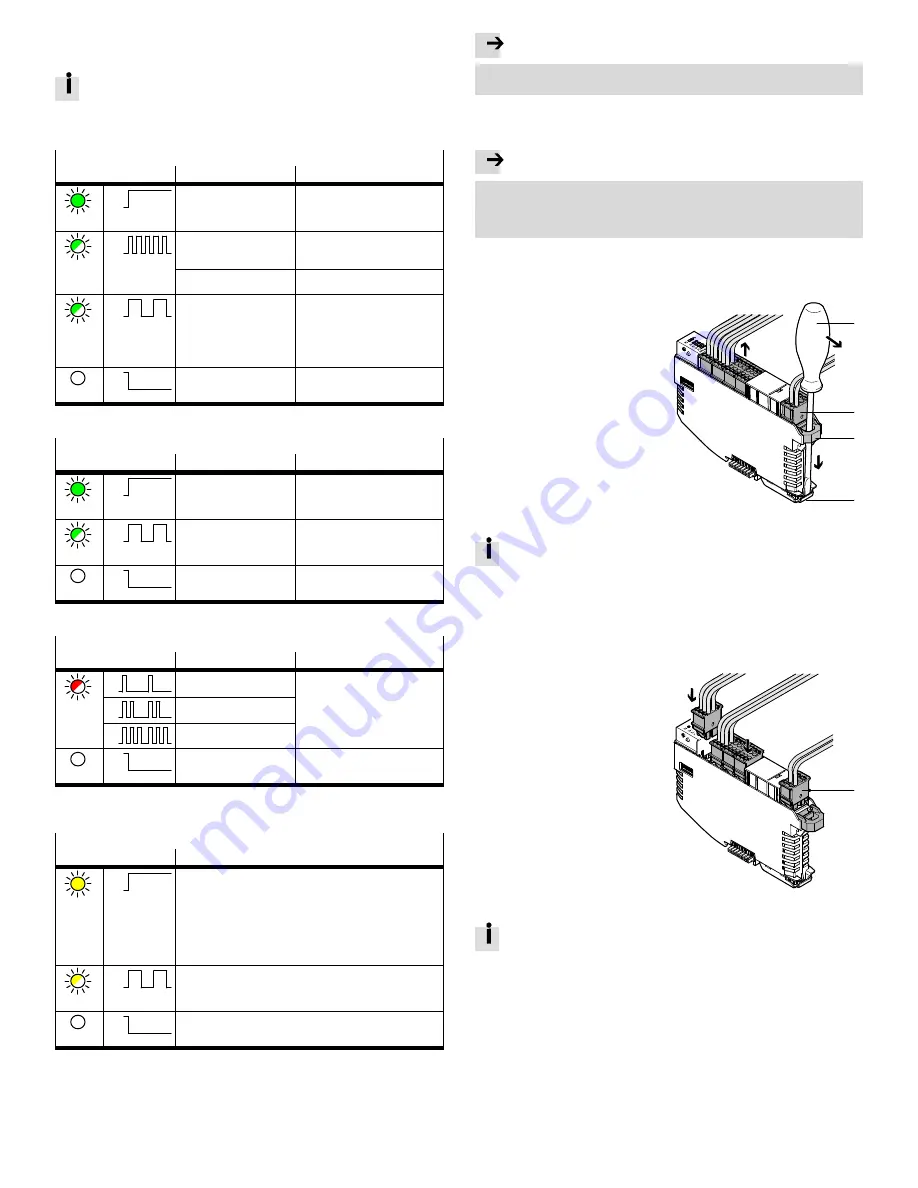

Removing the terminal strips

If a module is exchanged within the course of a conversion or repair, the conductor

remains in the terminal strip and the terminal strips are removed from the module.

1. Ensure that the module is

de-energised.

2. Insert the screwdriver through the

recess of the terminal strip interlock

and into the module interlock.

3. Pull the screwdriver in the direction

of the arrow to disengage the

terminal strips.

4. Remove the terminal strips.

1

2

3

4

2.

3.

4.

1

Screwdriver

2

Terminal strip

3

Interlock of terminal strips

4

Interlock of module

Fig. 19

After the terminal is disengaged, it remains in a stopped position. The ter

minal strips that are not removed must be pushed back in to the limit stop.

Disengaging and removing the module

è

Fig. 11

Hanging the module into place and engaging it

è

Fig. 10

Inserting terminal strips

1. Ensure that the module is

de-energised.

2. Place the terminal strips in the

appropriate positions on the module.

3. Press in the terminal strips to the

limit stop.

1

2.

3.

1

Terminal strip

Fig. 20

To prevent connection faults, the terminal strips of the signals and terminal

strips of the voltage supply have matching codes.