6

GENERAL FEATURES

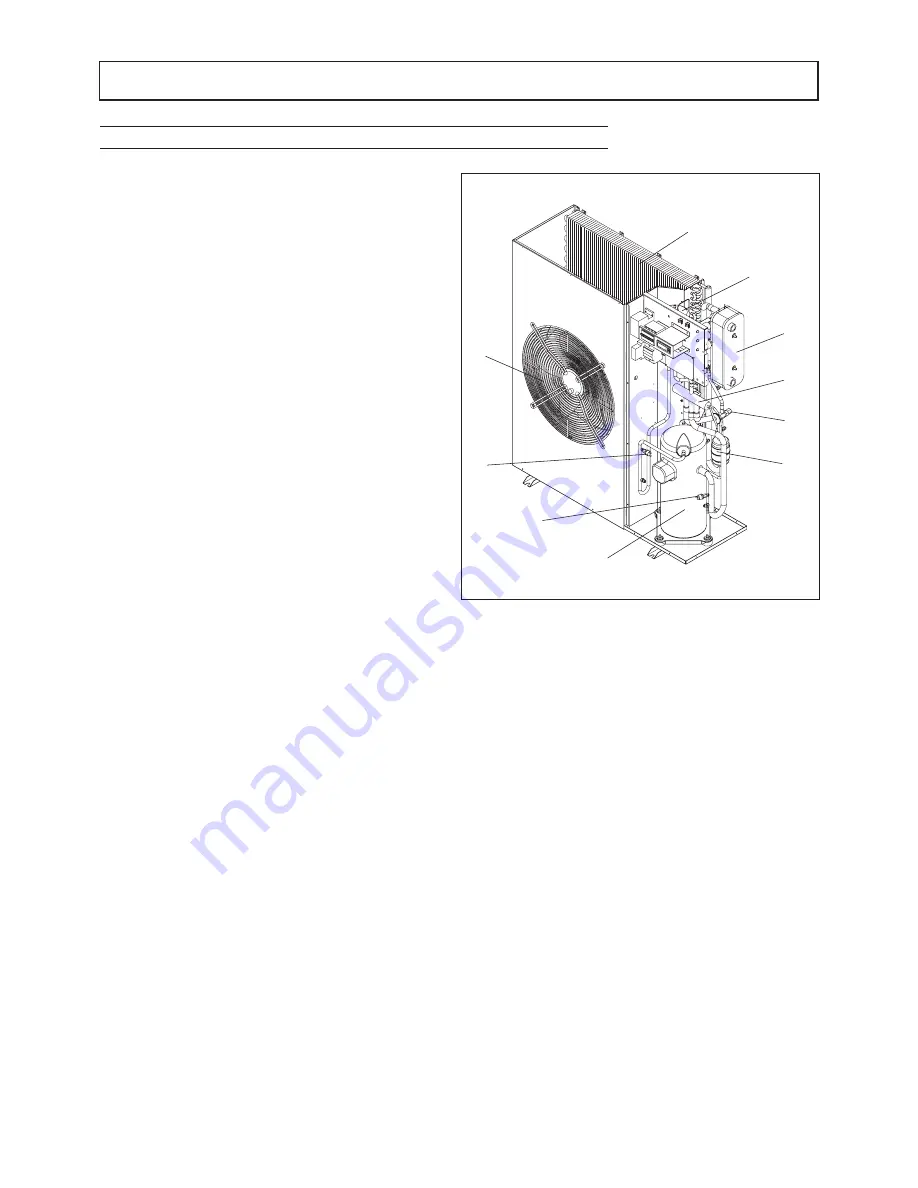

Description of parts

The

supporting structure (1)

, base and external panelling are

made from hot galvanised steel sheet, painted with epoxy

powers (colour RAL 7035) to ensure good resistance to

atmospheric agents.

The axial-type fans with curved profile blades

(2)

are housed in

a sheet casing and are complete with safety grille. Fan speed

is controlled in a continuous way by a phase cut device that

allows the condensing pressure (in cooling) and evaporation

pressure (in heating) to be controlled according to the value

read by the temperature probe on the liquid line.

The rotary type hermetic

compressor (3)

(models 6 or 7) or

scroll (models 9, 11, 14 and 17) is complete with

overtemperature and overcurrent protection. It is fixed to the

base by means of rubber vibration dampers and placed in a

compartment separate from the air flow to facilitate

maintenance and control operations. To prevent reverse

compressor rotation on all the units with three-phase power

supply, a device that controls the presence and correct

sequence of the power phases is fitted. Units in heat pump

version have a heating element that is activated when the

compressor switches off, to keep the compressor crankcase oil

temperature high enough to prevent migration of the refrigerant

during winter stops and to evaporate any liquid present in the

crankcase, in order to prevent possible liquid rushes on

starting.

The braze-welded stainless steel plate-type exchanger

on the

user side (4)

is adequately insulated to prevent the formation

of condensate and to limit heat loss to the outside. It is protected against the risk of ice forming by an antifreeze heating element

activated according to the water temperature and by a differential pressure switch that detects a possible lack of water flow.

The

external side exchanger (5)

comprises a finned coil with grooved copper pipes arranged in an equilateral shape and

aluminium fins with notched profile to increase the heat exchange coefficient. A tray is obtained in the base for collecting the

condensate produced during heating operation.

The lamination part

comprises a thermostatic valve

(6)

with external equaliser that allows the unit to adjust to the various

operation conditions, keeping the set level of overheating constant.

The refrigerant circuit of each unit is also complete with :

-

hermetic dehydrator filter

with solid cartridge

(7)

: it catches residuals of impurities and any traces of moisture in the circuit;

-

high pressure switch (8)

: with fixed setting and manual reset;

-

low pressure switch (9)

: with fixed setting and automatic reset (it becomes manual only in case of frequent activations);

-

4-way reverse cycle valve (10)

: it allows the switching of operation mode, reversing the refrigerant flow (for units in heat pump

version only);

-

liquid receiver (11)

: it compensates the variation in refrigerant charge required with the change of operation mode (for units in

heat pump version only);

-

pressure test points (12)

SAE 5/16” (UNF 1/2” - 20) complete with pin, seal and blind union, as required for the use of

refrigerant R410A. They enable a complete check of the refrigerant circuit : compressor inlet pressure, compressor delivery

pressure, pressure upstream of the thermostatic valve and pressure losses on the dehydrator filter.

1

2

3

10

9

5

4

6

7

8

Summary of Contents for RXA

Page 1: ...RXA AIR WATER CHILLERS AND HEAT PUMPS WITH AXIAL FANS TECHNICAL MANUAL...

Page 2: ...2...

Page 4: ...4...

Page 20: ...Cod 3QE23691...