Rendimax N EL

18

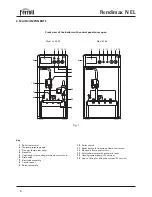

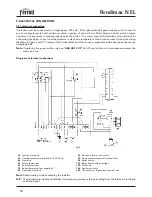

9. ELECTRICAL CONNECTIONS

9.01 electrical connection

The boiler must be connected to a single-phase, 230 volt - 50 hz (phase/neutral) power supply, with 3 a max fu-

ses, and a bipolar switch with minimum contact opening of at least 3 mm fitted between boiler and the source

of power. It is important to always properly earth the boiler. . The control panel is fitted with a terminal block for

connecting the boiler to any room thermostats or electronic temperature control units present (follow the wiring

diagrams in figs. 8 and 9). To access this terminal block and the various components inside the control panel, see

paragraph 9.02.

Note

If replacing the power cable, only use “

HAR H05 VV-F

” 3x0.75 mm

2

cables, with a maximum external dia-

meter of 8 mm

Diagram of electrical connections

fig. 8

Note

Dashed wiring to be handled by the installer

N.B.

The manufacturer declines all liability for damage to persons or things resulting from the failure to electrically

earth the boiler.

24

Ignition electrode

32

Heating system pump (models 16-23-30 pv)

44

Gas valve

49

Safety thermostat

63

Boiler thermostat

72

Room thermostat (not supplied)

82

Detection electrode

83

Electronic flame control unit

92

Flue gas thermostat with manual reset

98

Boiler switch

129

Reset button with pilot light

159

Test knob

160

Auxiliary contact

242

Connector for thermostatic control unit