PEGASUS D K 130

31

EN

EN

1. GENERAL WARNINGS

•

Carefully read and follow the instructions contained in this instruction booklet.

•

After boiler installation, inform the user regarding its operation and give him this manual, which is an integral and es-

sential part of the product and must be kept with care for future reference.

•

Installation and maintenance must be carried out by professionally qualified personnel, in compliance with the current reg-

ulations and according to the manufacturer's instructions. Do not carry out any operation on the sealed control parts.

•

Incorrect installation or inadequate maintenance can result in damage or injury. The Manufacturer declines any liabil-

ity for damage due to errors in installation and use, or failure to follow the instructions.

•

Before carrying out any cleaning or maintenance operation, disconnect the unit from the electrical power supply using

the switch and/or the special cut-off devices.

•

In case of a fault and/or poor operation, deactivate the unit and do not try to repair it or directly intervene. Contact

professionally qualified personnel. Any repair/replacement of the products must only be carried out by qualified per-

sonnel using original replacement parts. Failure to comply with the above could affect the safety of the unit.

•

This unit must only be used for its intended purpose. Any other use is deemed improper and therefore hazardous.

•

The packing materials are potentially hazardous and must not be left within the reach of children.

•

The unit must not be used by people (including children) with limited physical, sensory or mental abilities or without

experience and knowledge of it, unless instructed or supervised in its use by someone responsible for their safety.

•

The unit and its accessories must be appropriately disposed of, in compliance with the current regulations.

•

The images given in this manual are a simplified representation of the product. In this representation there may be

slight and insignificant differences with respect to the product supplied.

2. OPERATING INSTRUCTIONS

2.1 Introduction

Dear Customer,

Thank you for choosing

PEGASUS D K 130

, a floor-standing boiler

FERROLI

featuring

advanced design, cutting-edge technology, high reliability and quality construction.

Please read this manual carefully and keep it for future reference.

PEGASUS D K 130

is a high-efficiency heat generator for heating and domestic hot wa-

ter production running on natural gas or liquefied gas, with an advanced electronic con-

trol system.

The boiler shell consists of cast-iron elements whose particular shape guarantees high

exchange efficiency in all operating conditions and an open-flue burner equipped with

electronic ignition and ionisation flame control.

PEGASUS D K 130

is equipped with a vitrified, quick storage hot water tank protected

against corrosion by a magnesium anode .

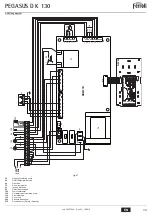

2.2 Control panel

Panel

fig. 1 - Control panel

Panel key

1 =

DHW temperature setting decrease button

2 =

DHW temperature setting increase button

3 =

Heating system temperature setting decrease button

4 =

Heating system temperature setting increase button

5 =

Display

6 =

Summer / Winter mode selection button

7 =

Economy / Comfort mode selection button

8 =

Reset button

9 =

Unit On / Off button

10 =

"Sliding Temperature" menu button

11 =

Set DHW temperature reached

12 =

DHW symbol

13 =

DHW mode

14 =

DHW outlet temperature / setting

15 =

Eco (Economy) or Comfort mode

16 =

External sensor temperature (with optional external probe)

17 =

Appears on connecting the external Probe or the Remote Timer Control (op-

tionals)

18 =

Room temperature (with optional Remote Timer Control)

19 =

Burner On

20 =

Antifreeze operation

21 =

Heating system pressure

22 =

Fault

23 =

Heating delivery temperature/setting

24 =

Heating symbol

25 =

Heating mode

26 =

Set heating delivery temperature reached

27 =

Summer mode

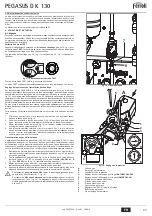

Indication during operation

Heating

A heating demand (generated by the Room Thermostat or Remote Timer Control) is in-

dicated by flashing of the hot air above the radiator (details 24 and 25 - fig. 1).

The heating graduation marks (detail 26 - fig. 1) light up as the heating sensor tempera-

ture reaches the set value.

fig. 2

DHW (Comfort)

A DHW demand (generated by drawing domestic hot water) is indicated by flashing of

the hot water under the tap (details 12 and 13 - fig. 1). Make sure the Comfort function

(detail 15 - fig. 1) is activated

The DHW graduation marks (detail 11 - fig. 1) light up as the DHW sensor temperature

reaches the set value.

fig. 3

Exclude hot water tank (economy)

Hot water tank temperature maintaining/heating can be excluded by the user. If exclud-

ed, domestic hot water will not be delivered.

When hot water tank heating is activated (default setting), the COMFORT symbol (detail

15 - fig. 1) is activated on the display, and when off, the ECO symbol (detail 15 - fig. 1)

is activated on the display

The hot water tank can be deactivated by the user (ECO mode) by pressing the eco/

comfort button (detail 7 - fig. 1). To activate the COMFORT mode, press the eco/comfort

button (detail 7 -

fig. 1)again.

2.3 Lighting and turning off

Boiler not electrically powered

fig. 4 - Boiler not electrically powered

B

The antifreeze system does not work when the power and/or gas to the unit are

turned off. To avoid damage caused by freezing during long idle periods in win-

ter, it is advisable to drain all water from the boiler, DHW circuit and system; or

drain just the DHW circuit and add a suitable antifreeze to the heating system,

complying with that prescribed in sec. 3.3.

Boiler lighting

•

Open the fuel shutoff valves.

•

Switch on the power to the unit.

fig. 5 - Boiler lighting

•

For the following 120 seconds the display will show FH which identifies the heating

system air venting cycle.

•

During the first 5 seconds the display will also show the card software version.

•

When the message FH disappears, the boiler is ready to operate automatically

whenever domestic hot water is drawn or in case of a room thermostat demand.

A

If, after correctly carrying out the lighting procedure, the burners do not light and

fault A01 appears on the display, wait about 15 seconds then press the RESET

button. The flame controller reset in this way will then repeat the ignition cycle.

If the burners do not light after a number of attempts, consult the anomalies par-

agraph.

eco

comfort

m

od

e

r e s e t

ecomfort

bar

5

7

9

10

2

1

8

6

4

3

12

14

11

13

15

16

17

18

20

21

22

23

25

24

26

27

19

eco

comfort

m

o

de

r e s e t

eco

bar

eco

comfort

m

o

de

r e s e t

comfort

bar

eco

comfort

m

od

e

r e s e t

eco

comfort

m

od

e

r e s e t

cod. 3540T644 - Rev. 0

-

/201

Summary of Contents for PEGASUS D 45 K 130

Page 78: ......

Page 79: ......

Page 80: ...FERROLI S p A Via Ritonda 78 a 37047 San Bonifacio Verona ITALY www ferroli it...