OPTIMAX HE 31 S

24

Cod. 3540F441 - 03/2007 (Rev. 01)

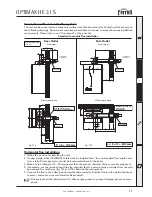

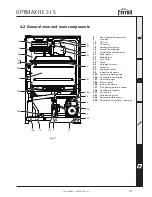

fig. 23

Injector Ø

Natural gas

LPG

See technical data table

3. SERVICE AND MAINTENANCE

3.1 Adjustments

All adjustment and conversion operations must be carried out by Qualified Personnel such as ferroli

Technical Service.

FERROLI declines any responsibility for damage or physical injury caused by unqualified and unauthorized

persons tampering with the device.

Gas supply conversion

The unit can function with either Natural Gas or LPG (commercial propane)and is factory-set for use with

one of the two gases, as clearly shown on the packing and on the unit’s dataplate. Whenever a different

gas to that for which the unit is preset has to be used, a conversion kit will be required, proceeding as

follows:

1

Remove the casing.

2

Open the airtight chamber.

3

Unscrew the gas coupling

A

on the air/gas mixer.

4

Replace the injector in the mixer with the one contained in the conversion kit.

5

Refit the coupling

A

and check the connection is gastight.

6

Apply the sticker, contained in the conversion kit, near the dataplate.

7

Fit the airtight chamber and casing back on.

8

Adjust the parameter for the specific type of gas to be used:

- Turn the boiler onto standby

- Press the DHW buttons

(part. 1, 2 - fig. 1) for 10 seconds: the display will show “P01”

blinking

- Press the DHW buttons

(part. 1, 2 - fig. 1) to set parameter 00 (for natural gas operation)

or 01 (for LPG operation)

- Press the DHW buttons

(part. 1, 2 - fig. 1) for 10 seconds

- The boiler will go back onto standby

9

Check working pressure.

10

Check CO

2

mixture as detailed (page 27 combustion analyser testing).

A

Summary of Contents for OPTIMAX HE 31 S

Page 36: ......