ECONCEPT TECH 18 A

29

EN

DHW temperature adjustment

Use the DHW buttons (detail 1 - fig. 1 ) to adjust the temperature from a min. of 10°C to

a max. of 65°C.

fig. 5

Room temperature adjustment (with optional room thermostat)

Using the room thermostat, set the temperature required in the rooms. If the room ther-

mostat is not installed, the boiler will keep the system at the set system delivery setpoint

temperature.

Room temperature adjustment (with optional remote timer control)

Using the remote timer control, set the required temperature in the rooms. The boiler will

adjust the system water according to the required room temperature. For operation with

remote timer control, please refer to the relevant instruction manual.

Hot water tank exclusion (economy)

Hot water tank temperature maintaining/heating can be excluded by the user. If exclud-

ed, domestic hot water will not be delivered.

The hot water tank can be deactivated by the user (ECO mode) by pressing the ECO/

COMFORT button (detail 7 - fig. 1). In ECO mode the display activates the ECO symbol

(detail 12 - fig. 1). To activate COMFORT mode, press the ECO/COMFORT button (de-

tail 7 - fig. 1) again.

Sliding Temperature

When the optional external probe is installed, the boiler adjustment system works with

"Sliding Temperature”. In this mode, the temperature of the heating system is controlled

according to the outside weather conditions, to ensure high comfort and energy saving

throughout the year. In particular, the system delivery temperature is decreased as the

outside temperature increases, according to a specific "compensation curve”.

With Sliding Temperature adjustment, the temperature set with the heating buttons (de-

tail 3 - fig. 1) becomes the maximum system delivery temperature. It is advisable to set

a maximum value to allow system adjustment throughout its useful operating range.

The boiler must be adjusted at the time of installation by qualified personnel. Possible

adjustments can in any case be made by the user to improve comfort.

Compensation curve and curve offset

Press the

reset

button (detail 6 - fig. 1) for 5 seconds to access the "Sliding temperature"

menu; the display shows "CU" flashing.

Use the DHW buttons (detail 1 - fig. 1) to adjust the curve from 1 to 10 according to the

characteristic. By setting the curve to 0, sliding temperature adjustment is disabled.

Press the heating buttons (detail 3 - fig. 1) to access parallel curve offset; the display

shows "OF" flashing. Use the DHW buttons (detail 1 - fig. 1) to adjust the parallel curve

offset according to the characteristic (fig. 6).

Press the

reset

button (detail 6 - fig. 1) again for 5 seconds to exit the "Sliding Temper-

ature" menu.

If the room temperature is lower than the required value, it is advisable to set a higher

order curve and vice versa. Proceed by increasing or decreasing in steps of one and

check the result in the room.

fig. 6 - Example of compensation parallel curve offset

Adjustments from Remote Timer Control

A

If the Remote Timer Control (optional) is connected to the boiler, the above ad-

justments are managed according to that given in table 1.

Table. 1

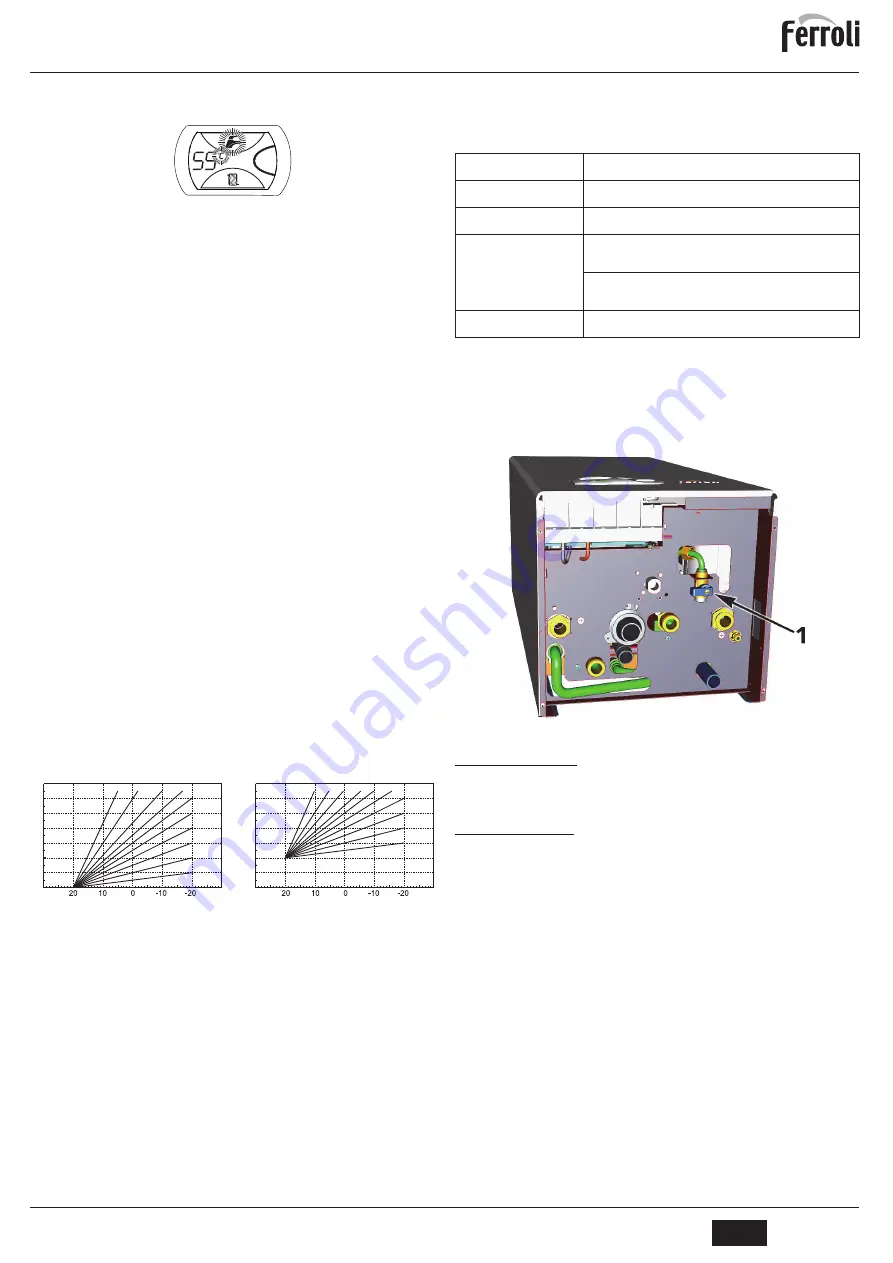

Plumbing system pressure adjustment

The filling pressure read on the boiler water gauge with the system cold must be approx

1.0 bar. If the system pressure falls to values below minimum, the boiler stops and fault

F37

is displayed. Bring it to the initial value by means of the filling cock detail 1 fig. 7. At

the end of the operation always close the filling cock.

Once the system pressure is restored, the boiler will activate the 120-second air venting

cycle indicated on the display by FH.

fig. 7 - Filling cock

3. INSTALLATION

3.1 General Instructions

BOILER INSTALLATION MUST ONLY BE PERFORMED BY QUALIFIED PERSON-

NEL, IN ACCORDANCE WITH ALL THE INSTRUCTIONS GIVEN IN THIS TECHNICAL

MANUAL, THE PROVISIONS OF CURRENT LAW, THE PRESCRIPTIONS OF NA-

TIONAL AND LOCAL STANDARDS AND THE RULES OF PROPER WORKMANSHIP.

3.2 Place of installation

The combustion circuit is sealed with respect to the place of installation, therefore the

unit can be installed in any room. However, the place of installation must be sufficiently

ventilated to prevent the creation of dangerous conditions in case of even small gas

leaks. This safety standard is required by the EEC Directive no. 2009/142 for all gas

units, including those with sealed chamber

The unit is suitable for operation in a partially protected place in compliance with EN 297

pr A6, for temperatures to -5°C. It is advisable to install the boiler under the slope of a

roof, inside a balcony or in a sheltered recess.

Therefore the place of installation must be free of dust, flammable materials or objects

or corrosive gases.

The boiler is arranged for wall mounting and comes standard with a hooking bracket. Fix the

bracket to the wall according to the measurements given in the cover drawing and hook the

boiler on it. A metal template for marking the drilling points on the wall is available by request.

The wall fixing must ensure stable and effective support for the generator.

A

If the unit is enclosed in a cabinet or mounted alongside, a space must be pro-

vided for removing the casing and for normal maintenance operations

20

30

40

50

60

70

80

90

85

20

30

40

50

60

70

80

90

85

1

2

3

4

5

6

8

9

10

7

1

2

3

4

5

6

8

9

10

7

OFFSET = 20

OFFSET = 40

Heating temperature setting

Adjustment can be made from the Remote Timer Control menu and the boiler

control panel.

DHW temperature adjustment

Adjustment can be made from the Remote Timer Control menu and the boiler

control panel.

Summer/Winter Switchover

Summer mode has priority over a possible Remote Timer Control heating

demand.

Eco/Comfort selection

On disabling DHW from the Remote Timer Control menu, the boiler selects the

Economy mode. In this condition, the

eco/comfort

button (detail 7 - fig. 1) on

the boiler panel is disabled.

On enabling DHW from the Remote Timer Control menu, the boiler selects the

Comfort mode. In this condition it is possible select one of the two modes with

the

eco/comfort

button (detail 7 - fig. 1) on the boiler panel.

Sliding Temperature

Both the Remote Timer Control and the boiler card manage Sliding Tempera-

ture adjustment: the boiler card Sliding Temperature has priority.

cod. 3540R794 - Rev. 02 - 02/2015

Summary of Contents for ECONCEPT TECH 18 A

Page 70: ......

Page 71: ......

Page 72: ...FERROLI S p A Via Ritonda 78 a 37047 San Bonifacio Verona ITALY www ferroli it ...