FERROLI F30

20

Fig. 21h

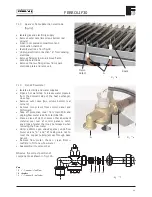

Fix with the screws (b). Refi t wiring connections to fan and air pressure switch tubes ensuring correct

orientation. I.E. red tube to air pressure switch connection with red dot (+) and clear tube to air pressure

switch connection with no paint marking (-).

Fit the fan into the boiler rotating the front to engage with the pin a. Secure with the screws b.

Rear

b

b

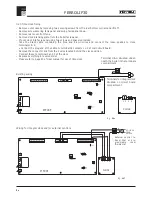

Back fl ue outlet (Diagram 1-9)

Fig. 22a

Fig. 22b

Fig. 22c

1.

Core drill 127mm hole (5").

2.

Push through the outer fl ue.

3.

Gently pull back until wall seal

is fl ush with the wall.

6.

Cut the outer fl ue fl ush with the

fl ange on the hanging plate.

80 mm

7.

Insert the aluminium fl ue pipe

into white plastic outer flue,

making sure the aluminium pipe

sits fully and centrally into the

fl ue terminal. Mark the aluminium

fl ue pipe at the point it is fl ush

with the mounting plate. Add

36mm to this mark and cut the

aluminium inner flue pipe at

this point.

Fig. 22g

36 mm

80 mm

Fig. 22f

Summary of Contents for Domina 102

Page 47: ......