Not for

Reproduction

5

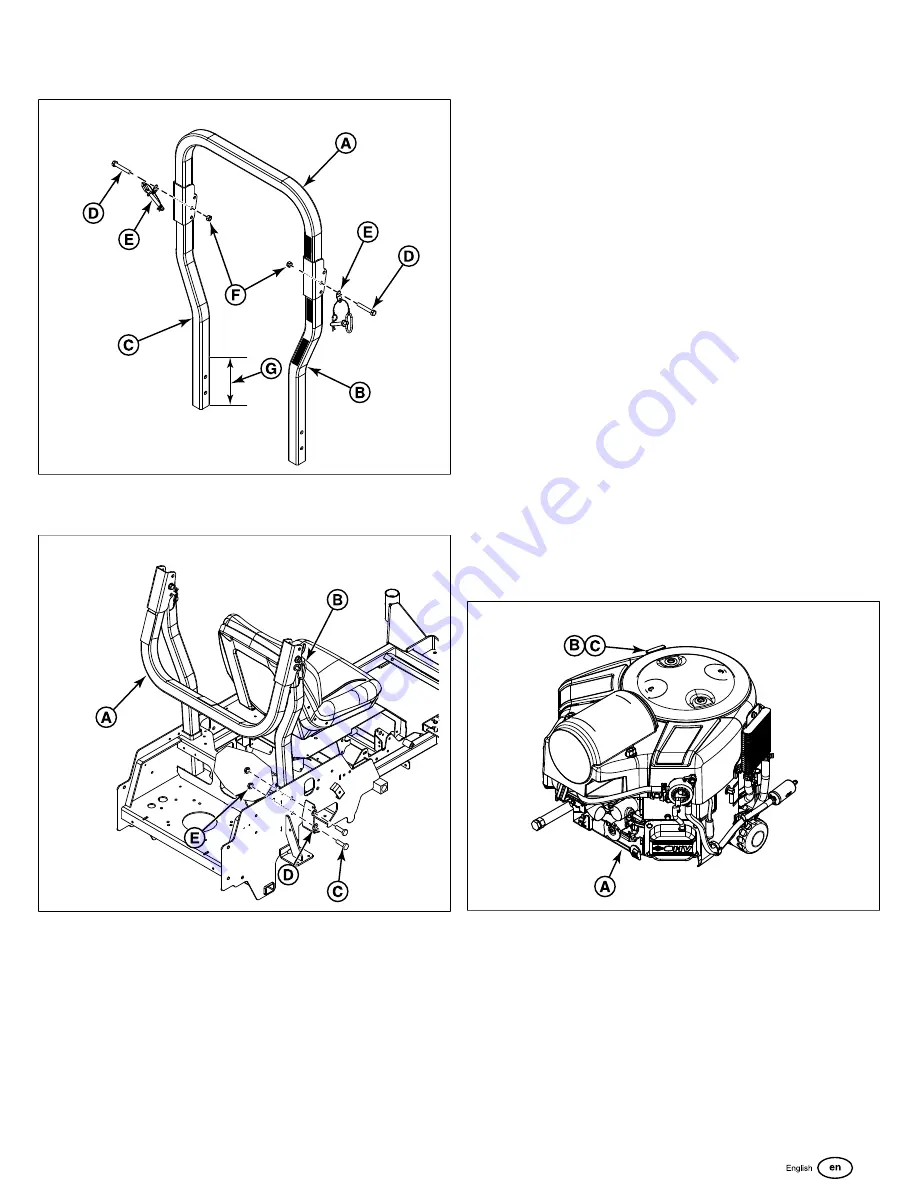

rear of the machine, the upright tube, and then loosely

install the 1/2 side lock nut (F).

6

2. Fold the roll bar to the down position (A, Figure 7) and

lock in place using the retainer pins and hair pin clips (B).

7

3. Make sure that no fuel lines, cables, or parts of the wire

harness are in the way of the roll bar pockets.

4. From the bottom of the roll bar upright tube measure up

8” (G, Figure 6) and mark the distance with a marking tool

or a piece of tape. Repeat for other upright tube.

5. Install the roll bar into the roll bar pockets. The roll bar is

installed so that the safety decals are on the left side of

the machine (as determined from the operator’s position)

facing towards the front of the machine. When the mark

you made is even with the top of the roll bar pocket, the

holes are close to being lined up. If necessary, use a

dead blow hammer and drift pin to assist in lining up the

holes in the roll bar with the holes in the roll bar pocket.

6. It may be necessary to remove the rear tires of the zero-

turn rider to install the roll bar mounting bolts. To remove

the rear tires jack up the rear end of the zero-turn rider,

secure with jack stands, and then remove the rear tires

from the unit.

7. Loosely install the (4) 1/2” bolts (C, Figure 7), and 1/2”

washers (D), through the frame of the unit, the roll bar,

the outer frame of the unit, and loosely install the 1/2” lock

nuts (E).

8. Tighten the 1/2” hardware that secures the upright tubes

to the frame of the unit to 82 ft. lbs (108 Nm) of torque.

9. Tighten the 1/2” bolt and side lock nuts that secure the

top loop to the upright tubes. Do not over-tighten. The top

loop should pivot snugly with the retainer pins removed.

10. If the rear tires were removed from the unit re-install them

now. The lug nuts should be torqued to 90 ft. lbs. (122

Nm). Remove the jack stands from underneath the zero-

turn rider.

11. Raise the top loop to the upright position and install the

retainer pins and hair pin clips to secure the roll bar in the

raised position.

Check the Engine Oil level

This model is equipped with a Briggs & Stratton Commercial

Turf Series engine (A, Figure 8)

8

1. Use the dipstick (B) to check the engine oil level. If

necessary add engine oil through the engine oil fill (C).

Check the engine manufacturer's owner's manual for oil

recommendations.

Check / Fill Transmission Oil Level

This unit is equipped with two transmission oil tanks. One

transmission oil tank only supplies oil to one transmission.

The level of oil in both transmission tanks must be checked,

and if necessary, filled.

Oil Type:

20W-50 conventional detergent motor oil