7

EN

Mains plug replacement (UK only)

If the moulded 3-pin plug attached to the unit is

damaged and needs replacing, it is important that

it is correctly destroyed and replaced by an

approved BS 1363/5A fused plug and that the

following wiring instructions are followed.

The wires in the mains cable are coloured in

accordance with the following code:

blue

neutral

brown live

As the colours of the wires in the mains cable of

the unit may not correspond to the coloured

markings identifying the terminals in the plug,

proceed as follows:

- The wire which is coloured blue must be

connected to the terminal which is marked with

the letter N or coloured black.

- The wire which is coloured brown must be

connected to the terminal which is marked with

the letter L or coloured red.

TECHNICAL DATA

AGM1042

Mains voltage

V~ 230

Mains frequency

Hz 50

Power input

W 750

No-load speed

min

-1

11,000

Grinding disc

Diameter

mm 115

Bore

mm 22.2

Spindle thread

M14

Weight

kg 2.2

NOISE AND VIBRATION

AGM1042

Sound pressure (L

pa

)

dB(A) 87.7

Acoustic power (L

wa

)

dB(A) 98.7

Uncertainty (K)

dB(A) 3

Vibration

m/s

2

7.52

Uncertainty (K)

m/s

2

1.5

2

Wear hearing protection.

Vibration level

The vibration emission level stated in this instruction

manual has been measured in accordance with a

standardised test given in EN 60745; it may be used

to compare one tool with another and as a

preliminary assessment of exposure to vibration

when using the tool for the applications mentioned

- using the tool for different applications, or with

different or poorly maintainted accessories,

may significantly increase the exposure level

- the times when the tool is switched off or when

it is running but not actually doing the job, may

significantly reduce the exposure level

Protect yourself against the effects of vibration by

maintaining the tool and its accessories, keeping

your hands warm, and organizing your work

patterns

M

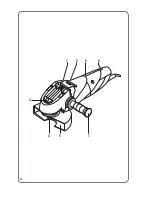

DESCRIPtION (fIG. A)

Your angle grinder has been designed for grinding

and cutting masonry and steel.

1. On/off switch

2. On/off switch lock

3. Spindle lock button

4. Spindle

5. Guard

6. Main grip

7. Auxiliary grip

8. Carbon brush indicator

ASSEMBLy

4

Before assembly, always switch off the

machine and remove the mains plug

from the mains.

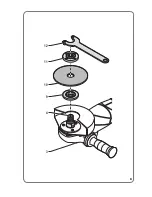

Mounting and removing the grinding disc

(fig. B)

2

Never attempt to remove the guard.

Mounting

● Place the machine on a table with the guard

(5) facing upwards.

● Mount the spacer (9) onto the spindle (4).

● Mount the grinding disc (10) onto the spindle (4).

● Keep the spindle lock button (3) pressed and

firmly tighten the tension nut (11) using the

spanner (12).

Removing

● Place the machine on a table with the guard

(5) facing upwards.

● Keep the spindle lock button (3) pressed and

loosen the tension nut (11) using the spanner

(12).

● Remove the grinding disc (10) from the spindle

(4).

Summary of Contents for AGM1042

Page 2: ...3 7 5 4 6 8 2 1 A...

Page 3: ...12 11 10 9 4 3 B...

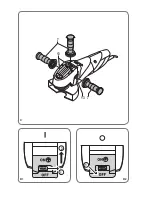

Page 4: ...A 13 7 13 7 D1 C D2 1 2 1...

Page 90: ...90 RU 6 5 I J K 8 9...

Page 91: ...91 RU 80 3 1 5 2...

Page 93: ...93 RU D 2 1 D1 1 D2 4 8 8 2002 96...

Page 94: ...94 UA AGM1042 Ferm Ferm 1 1 2 3 4 6 5 I J K 8 9...

Page 95: ...95 UA 80...

Page 97: ...97 UA 4 2 5 9 4 10 4 3 11 5 3 11 10 4 3 11 7 13 D 2 1 D1 1 D2 4 8 8...

Page 98: ...98 EL 2002 96 EC AGM1042 Ferm Ferm 1 1 2 3 4 6...

Page 99: ...99 EL 5 I J K 8 9...

Page 100: ...100 EL 80 3 1 5 mm2 AGM1042 V 230 Hz 50 W 750 min 1 11 000 mm 115 mm 22 2 M14 kg 2 2...

Page 102: ...102 EL 4 8 8 2002 96 E...

Page 104: ...104...

Page 105: ...105...

Page 107: ...107 Exploded view...

Page 108: ...2009 Ferm B V...