Troubleshooting guide

December 10, 2019,

4

FELIX

Pro series

Felix Pro L/XL

4

Step by step troubleshooting:

The next chapters show step by step how to resolve the issue. Beginning with the most likely and simple solution

first.

4.1

Check if the machine is able to home again after heating both nozzles.

In some cases cooled down filament in the (not)-used extruder pulls the hot-ends slightly upwards, causing a

(sometimes constant) false trigger. To check if this is the case, heat both extruders to at least 180°C. Check if you

can home again once both extruders have reached their target temperature.

On the touch screen you can type

in m119 into the console to check if a probe is stated high, thi

s means it’s not making a good enough contact.

The latest firmware releases automatically heat the extruders to 185°C when performing probing actions,

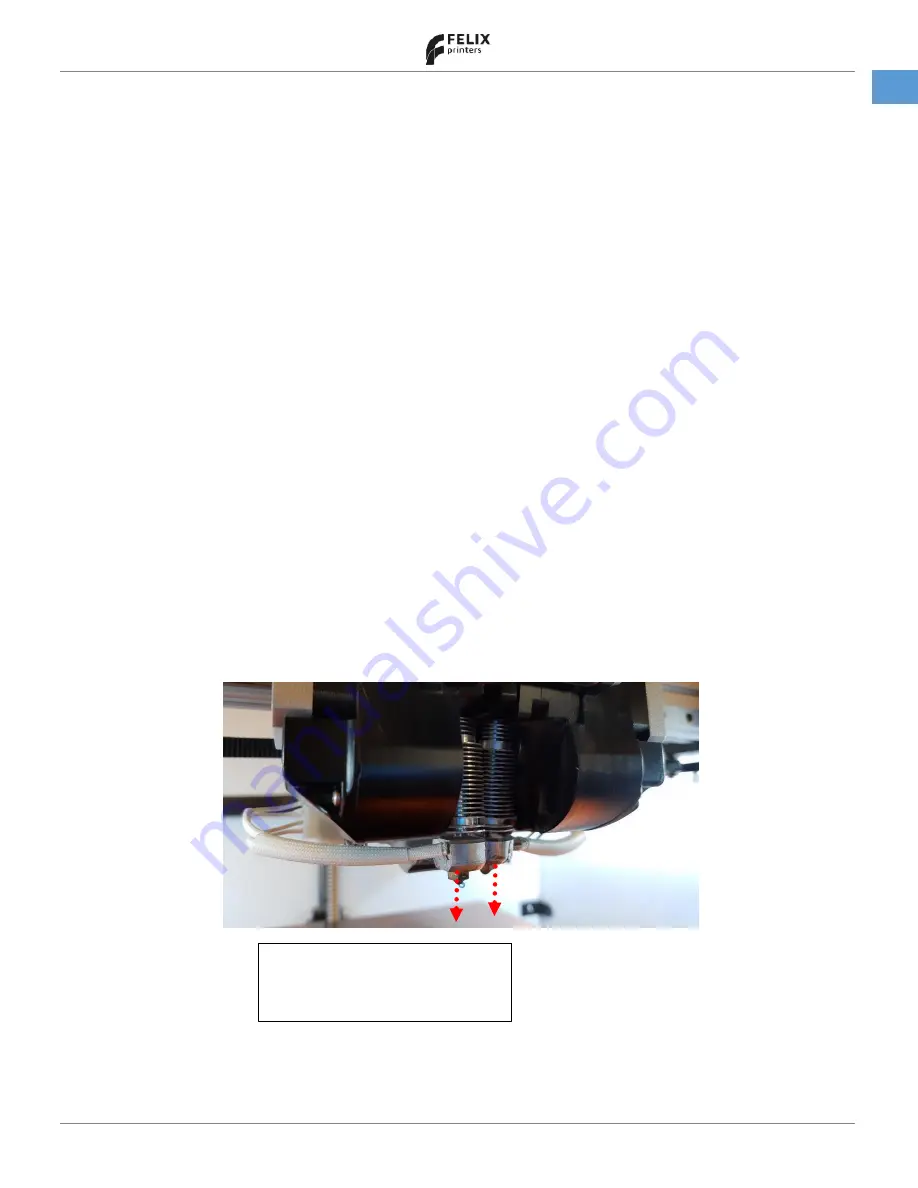

Are the hot-ends fully pushed downwards against the contact points? During transport or after pulling out the

filament by hand sometimes the hot-ends can be detached from one of the magnetic contact points.

You can

usually reset the probe by pushing some filament through by hand

.

4.2

Use the latest and correct slicing settings.

Using sliced files not optimized for the FELIX Pro series can result in bad prints. To ensure proper probe action, in

the startup g-code we have implemented some commands which force the hot-ends on their contacts prior to the

start of a print job.

4.3

Detect which hot-end gives problems

If the message does not go away, please check next step.

Pull down both hot-ends (while

cold) and check if the

machine

is able to home again