5

en

Safety instructions.

When performing drilling that requires the

use of a fluid, route the fluid away from the

operator’s work area or use a collection sys-

tem.

Such precautionary measures keep the

operator’s work area dry and reduce the

risk of electrical shock.

Operate the power tool by the insulated grip-

ping surfaces, when performing an opera-

tion where the cutting accessory may

contact hidden wiring or its own cord.

Con-

tact of a cutting accessory with a "live" wire

may make exposed metal parts of the power

tool "live" and could give the operator an

electric shock.

Wear hearing protection when drilling.

Exposure to noise can cause hearing loss.

When the application tool jams, stop apply-

ing pressure and switch the power tool off.

Check the cause of the jam and apply cor-

rective action to eliminate the cause of the

jamming application tool.

When restarting a core drill jammed in the

workpiece, check that the application tool

rotates freely before starting.

If the applica-

tion tool is jammed, it may not start, may

overload the power tool, or may cause the

core drill to release from the workpiece.

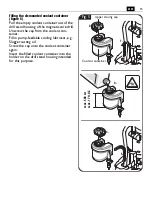

When securing the drill stand with a vacuum

plate to the workpiece, make sure that the

surface is smooth, clean and non-porous. Do

not secure the drill stand to laminated sur-

faces such as tiles and coated composite

materials.

If the surface of the workpiece is

not smooth, flat or well affixed, the vacuum

plate may pull away from the workpiece.

Ensure there is sufficient vacuum level

before and during drilling.

If the vacuum

level is insufficient, the vacuum plate may

become detached from the workpiece.

Never perform overhead and wall drilling

when the machine is only fastened using the

vacuum plate.

If the vacuum is lost, the vac-

uum plate will release from the workpiece.

When drilling through walls or ceilings,

ensure to protect persons and the work area

on the other side.

The core bit may extend

through the hole or the core may fall out on

the other side.

Do not use this tool for overhead drilling

with fluid supply.

Fluids entering the power

tool will increase the risk of electric shock.

Special safety instructions.

Have the protective cable bushing replaced

immediately when damaged.

A defective

protective cable bushing can lead to over-

heating of the machine.

Wear protective equipment. Depending on

the application, wear face shield or safety

goggles. Wear hearing protection.

The

safety glasses/goggles must be suitable to

protect against the particles emitted from

different operations. Continuous high expo-

sure to noise can lead to loss of hearing.

Do not touch the sharp edges of the core drill

bit.

Danger of injury.

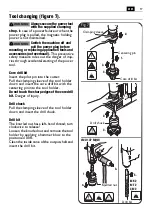

To avoid injuries, check the core drill bits

prior to starting the work. Use only undam-

aged core drill bits that are not deformed.

Damaged or deformed core drill bits can

cause serious injury.

Before putting into operation: Mount the

chip guard to the machine.

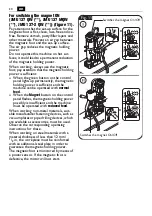

Always secure the machine with the

supplied safety strap.

Especially on

inclined or uneven surfaces there is risk

of unsecured machines tipping over.

When working overhead, beware of falling

objects, such as cores or chips.

When working overhead or on vertical sur-

faces, the coolant container must not be

used.

Use Slugger Cutting Paste instead. Liq-

uids penetrating your electric power tool

maycause electric shock.

Avoid touching the drilled core that is auto-

matically ejected by the pilot pin when the

working procedure is finished.

Contact with

the core when it is hot, or if it falls, can cause

personal injuries.

Operate the power tool only from grounded

contact sockets that comply with the speci-

fications. Do not use any connection cables

that are damaged; use extension cables

with a grounded contact that are checked at

regular intervals.

A ground conductor with-

out continuity can cause an electric shock.