21

en

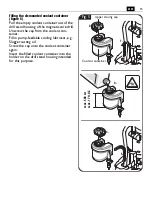

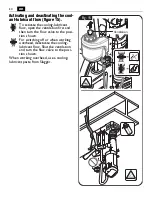

For switching the magnet ON

(JMU 137 PQW (**)) (figure 12).

Pay attention that the set-up surface for

the magnetic foot is flat, clean, rust-free

and ice-free. Remove varnish, putty/filler

layers and other materials. Prevent an air gap

between the magnetic foot and the set-up

surface. The air gap reduces the magnetic

holding power.

Do not operate this machine on hot

surfaces; it could lead to a permanent

reduction of the magnetic holding power.

When working, always use the magnetic

foot; pay attention that the magnetic

holding power is sufficient:

–

When the green button on the control

panel lights up permanently, the magnetic

holding power is sufficient and the

machine can be operated with

normal

feed

.

–

When the

Magnet

button on the control

panel flashes, the magnetic holding power

possibly is insufficient and the machine

must be operated with

reduced feed

.

When working non-magnetic materials,

suitable FEIN fastening devices, such as vac-

uum plates or pipe drilling devices, which

are available as accessories, must be used.

Observe the corresponding operating

instructions for these.

Even when working on steel materials

where the material thickness is below

12 mm, the workpiece must be made

thicker with an additional steel plate in order

to ensure the magnetic holding power.

The magnetic holding power can be

switched step by step with the hand lever.

For positioning, set the hand lever to the

30 % position; to switch the magnet on, set

the hand lever to the 100 % position.

Fig. 12

Hand lever,

magnet

100%

30%

0%

100%

30%

0%

> 12 mm

< 12 mm

30%

100%

2.

2.

1.

1.