Maintenance every year

BOMAG

46

BT 60/4, BT 65/4

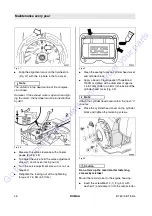

Fig. 47

l

Align the alignment mark on the flywheel rib

(Fig. 47) with the top bore in the fan cover .

Note

i

The piston is in top dead centre of the compres-

sion stroke.

However, if the exhaust valve is open when align-

ing the marks, the flywheel must be turned further

by 360°.

Fig. 48

l

Measure the valve clearance with a feeler

gauge (2) (Fig. 48).

l

To adjust the valve hold the valve adjustment

screw (1) and loosen locking nut (3).

l

Turn the valve adjustment screw in or out, as

required.

l

Retighten the locking nut with a tightening

torque of 7.5 Nm (5.5 ft.lbs).

Fig. 49

l

Clean the sealing faces on cylinder head cover

and cylinder block.

l

Apply a bead of liquid gasket (Three Bond

1207B or similar) with a diameter of approx.

1.5 to 2 mm (0.06 to 0.08 in) to the inside of the

cylinder head cover (Fig. 49).

Note

i

Attach the cylinder head cover within the next 10

minutes.

l

Place the cylinder head cover on the cylinder

block and tighten the fastening screws.

Fig. 50

Caution

!

Do not mix up the recoil starter fastening

screws by mistake!

Mount the recoil starter to the engine housing:

l

Insert the screw M6x12 (1) (Fig. 50) with

washer (2) and clamp (3) into the recoil starter.

Go

to

Discount-Equipment.com

to

order

your

parts