47

5.7.2. Front wheels toe-in.

Toe-in measurement and adjustment .

Check and adjust the front wheel toe-in every 600 hours of operation and after every change in the

track setting and when excessive tyre wear is noticed.

To adjust front drive axle toe-in:

dismount the track rod,

loosen the lock nut of track rod at each track rod end,

shorten or lengthen the track rod by track rod ends rotating. Adjustment must be made equally

to both track rod ends,

refit the track rod to the front axle and tighten the lock nuts, to the torque of 140 Nm,

recheck the toe-in and adjust, if necessary.

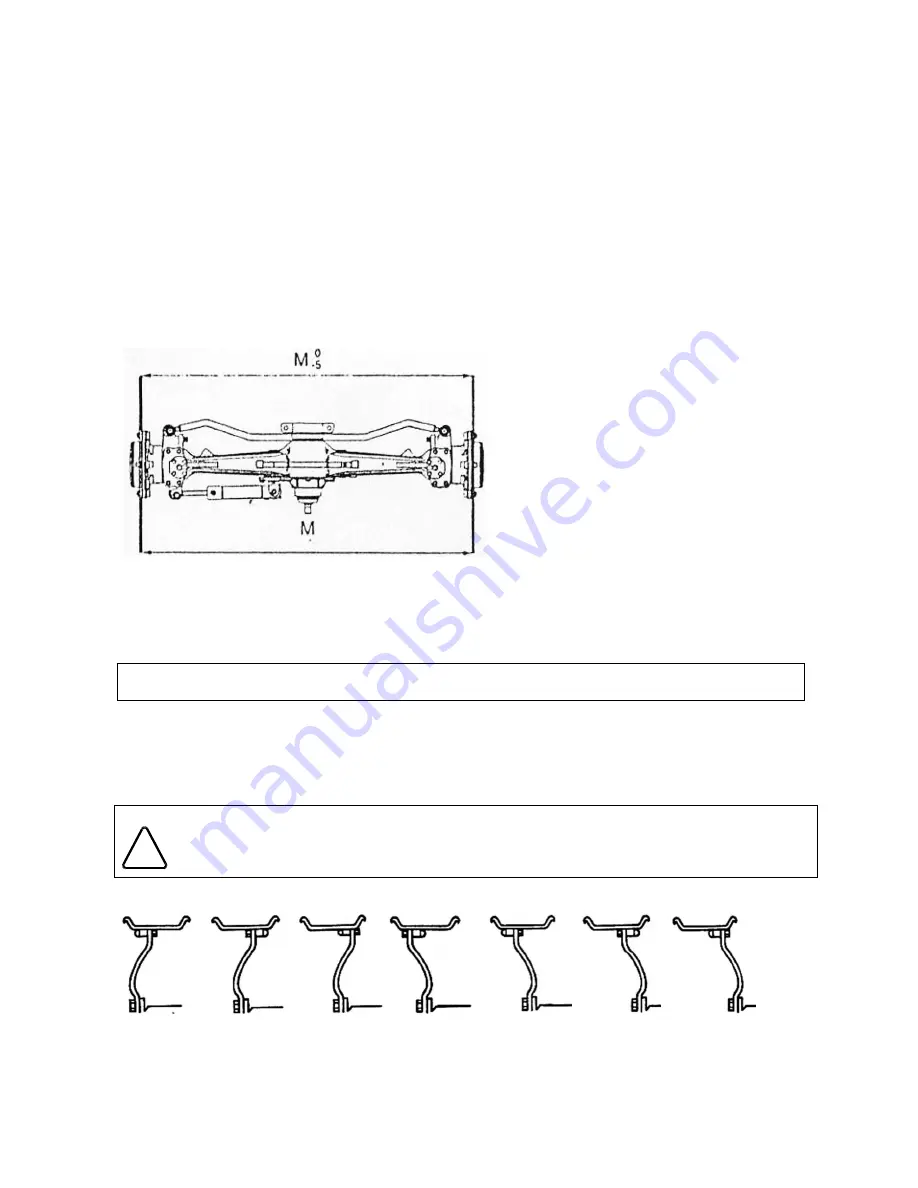

Fig. 5.7.1. Front drive axle toe-in adjustment

5.7.3. Rear wheel track adjustment.

Rear wheel track adjustment is effected by changing the position of the wheel rim in relation to the

disc and/or of the disc in relation to the axle hub as well as by reversing the wheels and

interchanging them. There are six possible settings (Fig. 5.7.3).

NOTE:

If the wheels are reversed, they must be transferred to the opposite sides of the

tractor so as to maintain the correct direction of the tyre tread.

When refitting or adjusting a wheel, tighten the nuts/bolts progressively to the following torque:

rim to disc

–

176 Nm,

disc to axle hub

–

270 Nm

.

WARNING:

!

Recheck after driving the tractor 200 m and then twice at 10 hour interval. If heavy

work is involved, check twice at 2 hour interval until torque is held according to the

values as given above.

1350

(standard)

1445

1575

1655

1765

1875

1985

Fig. 5.7.3 Rear wheel track