15

GB

KJ 45

KJ 45

Revision - 04

Date 10-2008

f3

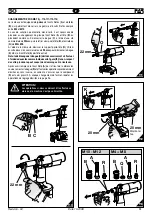

Tie rod min. stroke

Revolutions (M)

~ 2 mm

0

Tie rod stroke

Revolutions (M)

~ 0.4 mm

1

Tie rod max. stroke

Revolutions (M)

~ 8 mm

15

+

-

0

1

2

3

4

5

6

7

9

8

10

11

12

13

14

15

M12

1 ÷ 4

M4

0.3

÷ 4

M5

0.5 ÷ 5

M8

0.8 ÷ 6

M10

1 ÷ 6

M12

1 ÷ 7

/

M6

0.5 ÷ 6

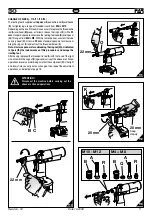

PLACING OF THE INSERT

(fi g.

f4-f5-f6

)

Check that the threaded tie rod (

A

) and head (

B

) couple assembled on

the riveting tool is suitable to the size of the insert to be used.

Adjust the stroke as indicated (fi g.

f2-f3

).

Introduce the insert on the tie rod (

A

) and push slightly on it as indicated

in fi gure

f4

, so as to make it clamp automatically on the threaded tie

rod. Make sure that the insert head touches the head (

B

) checking

that the tie rod (

A

) comes out of

2mm

from the insert.

In case of further adjustments of the tie rod (

A

) follow the instructions

of page 18.

It is possible to place the insert pushing the button (

D

) and keeping it

pushed up to the complete release of the tie rod (fi g.

f5

).

For a correct placing and right working of the machine, the inserts to

be used should be properly cleaned.

Note:

According to the desired clamping, carry out other adjustments

of the riveting tool stroke, rotating the knob (

M

) (fi g.

f2-f3-f6

), if

necessary.

Insuffi cient deformation =

the insert could rotate inside the housing

compromising its use and resistance.

Excessive deformation =

possible damages of the insert and tie rod

(

A

) with eventual breaks of both components.

D

M

f5

f4

~2mm

A

B

f6

Summary of Contents for KJ45

Page 79: ......