Installation Preparation

A

Mark the door.

a. Fold the template as shown with the fold on the high edge

of door bevel. Position template centerline on door height

line (suggested height is 38" (97 cm) from finished floor).

b. Mark the door at positions indicated:

• One 2

Z\,

" hole

• Two notches on sides of the 2

Z\,

" hole (notches must be

horizontal)

• Two through-bolt holes

• One latchbolt hole on the door edge.

L

For single dummy function (T12), mark only the two

through-bolt holes.

L

If preparing a door with existing 2

Z\,

" hole, fold the template in

half to mark the positions for two through-bolt holes. Be sure to

mark positions for the notches.

L

If steel frames are used, the latch centerline must be in line with

the center of the strike preparation on the frame.

High Edge Of Bevel Door

TEMPL

ATE FOR

INS

TALLING

T–SERIES LEVER

LOCKS

LATCH

MARK CENTER FOR

5/16"(8mm) HOLES

USING DRIL

L FIXTURE

030736-000-50 IS

RECOMMENDED

TO

ENSURE PROPER

ALIGNMEN

T OF

THRU-BO

LT

HOLES.

2 3/4"(70mm) BACKSET

MARK CENTER FOR

2 1/8"(54mm) HOLE

IMPO

RTAN

T:

CHECK LOCK FOR PROPER

BACKSE

T BEFORE DRILLING

5/32"(4mm)

5/32"(4mm)

x1/8"(3mm) DEEP

RD

)

m

m1

5("

2

2

1

/

4

RD

)

m

m7

5("

1

3

/

4

RD

)

m

m5

4("

TN

E

MT

SU

JD

A

GNI

RE

TN

EC

RO

OD

FOLD HERE &

PLACE ON HIGH

EDGE OF DOOR

MARK CENTERLINE OF L

ATCH

FOR CORREC

T DOOR

THICKNESS.

DRIL

L 1"(25mm) DI

A HOLE.

EG

DE

H

GI

H

1 3/4"

(45mm)

2"(51mm)

2 1/4"(57mm)

Notches

Through-bolt

holes

2

Z\,

" hole

High

edge

of door

bevel

Latchbolt

hole

*030794*

030794

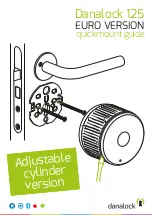

T-Series

Extra Heavy Duty Lockset

Installation Instructions

IMPORTANT: This lock is non-handed. Lock is factory packed preadjusted for 1

C\v

" (45 mm) thick doors. To adjust the lock for other

door thickness, see "Adjust for door thickness (if necessary)". Spacers must be used for doors thinner than 1

C\v

" (45 mm) thick. For

functions T351, T381, T561 and T571, see "Timing instructions" for standard cylinder and IC core cylinder timing instructions.

For single dummy function (T12), go to step 7.

LH

Left Hand

LHR

Left Hand

Reverse Bevel

RH

Right Hand

RHR

Right Hand

Reverse Bevel

INSIDE

INSIDE

OUTSIDE

OUTSIDE

Door hand is determined from the outside.

Chassis

assembly

Spacer*

Spacer*

Outside trim assembly,

standard cylinder

Latch mounting screws

Inside mounting plate

Latch assembly

Flanged nut

Outside trim assembly,

IC cylinder

Inside trim

assembly

Rose

Trim mounting screws,

#10-32 x 1"

Set screw,

Z\v

-20 x

Z\v

"

Inside lever

*Spacer required for doors less than 1

C\v

" thick.

LHR Shown

See page 5 for explanation of

Warnings, Cautions and Notices.