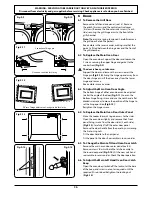

INSTALLATION

Check the appliance is electrically safe and gas sound when you have finished.

26

Gas Connection

Must be in accordance with the relevant standards.

The gas supply needs to terminate with a threaded fitting ½”.

The inlet connector is located just below the hotplate level at

the rear of the cooker.

Because the height of the cooker can be adjusted and

each connection is different it is difficult to give precise

dimensions. Ideally, the house supply connection should be

in the shaded area

(Fig.7-10)

.

Means of isolation must be provided at the supply point by

either an approved quick-connect device or a Type 1 manual

shut-off valve.

The hose should be fitted so that both inlet and outlet

connections are vertical so that the hose hangs downwards in

a ‘U’ shape

(Fig.7-10)

.

A flexible connection is supplied with the cooker. If it is

necessary to use another hose it must be to AS 1869 Class

B and be suitable for your gas type. If in doubt contact your

supplier. Screw connect the threaded end of the hose into the

gas inlet.

After completing the gas connection, check the cooker is gas

sound with a pressure test. When checking for gas leaks do

not use washing up liquid – this can corrode. Use a product

specifically manufactured for leak detection.

Natural Gas

The adjustable spring loaded gas pressure regulator is preset

to give a nominal pressure of 1 kPa on Natural gas. Connect to

the Rp ½ inlet on the underside of the pressure regulator.

Propane

This cooker is supplied ready for use on Natural gas. A

conversion kit for Propane gas is supplied with the cooker –

see the ‘

Conversion to Propane Gas

’ section.

Pressure Testing

The pressure test point is accessible on the inlet pipe at the

rear. Remove the test nipple screw and fit a pressure gauge to

the test point. Turn on and light two of the hotplate burners.

For Natural Gas cookers the pressure should be between

0.95kPa and 1.0kPa.

For Propane X cookers the pressure should be 2.54 kPa.

ArtNo.090-0027 - 90 Elan gas connections

300

100

240

100

All dimensions in millimetres

Gas inlet

Fig.7-10