10 F

FA

AG

G

2.3 Unit Check-up

2.4 Mechanical Connection

These devices are checked before despatch

and sent away in perfect condition.

Should the damage to a device be visible,

we recommend a thorough inspection of the

delivery packing. In case of damage, please

inform your parcel service/forwarding agent

immediately, since they are responsible for

damages during transit.

B

Be

effo

orre

e iin

nsstta

alllla

attiio

on

n::

– Ensure that the max. pressure in your

system is within the prescribed range of

digital manometer. The measuring range

can be read from the type label of device.

– Make sure that the permitted max.

operational temperature of device is not

exceeded.

– Ascertain that the electrical power supply

to the unit is in agreement with the

operational data of the unit.

– Please confirm that there are no parts of

packing material present inside the unit.

IIn

nsstta

alllla

attiio

on

n::

– Ensure that the piping has no pressure

inside.

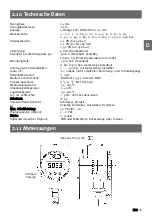

– The digital manometer should be mounted

just like a mechanical manometer.

– With standard thread connection, sealing

is achieved by means of a suitable gasket

(flat-seal or seal-ring (DIN 16258).

– While screwing in the device, rotate the

hexagonal screw (SW 24) and not the

housing.

– If possible, please check after the

mechanical installation, whether the con-

nection joint is adequately sealed or not..

– Open the battery enclosure on the back-

side of the unit and connect the 9V block

battery with the connection plug.

– Place the 9V block battery in the enclosure

and close it with the lid.

– The digital pressure gauge may only be

used with a 9 VDC block battery

S

Scco

op

pe

e o

off d

de

elliiv

ve

erry

y::

Standard scope of delivery applies on:

– Transmitter with display

– Service manual

– 9 VDC - Block battery

Flat seal-ring acc. to

DIN 16 258

GB

Summary of Contents for PUMP1600

Page 2: ......