27

EN

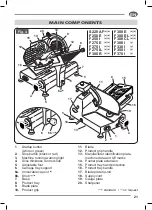

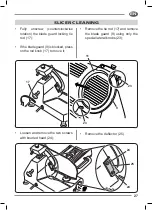

SLICER CLEANING

• Fully unscrew (counterclockwise

rotation) the blade guard locking tie

rod (17);

• If the blade guard (9) is blocked, press

on the rod knob (17) to move it;

• Remove the tie rod (17) and remove

the blade guard (9) using only the

special lateral knobs (23);

• Loosen and remove the two screws

with knurled head (24);

• Remove the deflector (25).

24

24

25

23

23

11

9

17

26

4

5

6

7

8

3

2

EN

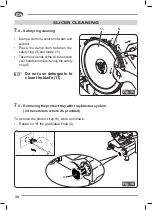

SLICER CLEANING

The machines have to be carefully cleaned at least once a day; if it is

necessary more frequently. After a shorter or longer period of inactivity

clean the slicer before use.

WARNING: Cutting hazard!

Use protective cut- and tear-resistant gloves and perform

all operations with extreme care.

PAY ATTENTION AT ALL TIMES!

7

.1 - Disassembling the machine for cleaning

• Disconnect the plug from the mains power supply.;

Take to ‘0’ the adjustment knob of the gauge plate (4);

☞

• Remove the various components as described in the following paragraphs;

4

Summary of Contents for S220

Page 2: ......

Page 4: ......

Page 50: ...48 EN...

Page 52: ...50 EN...

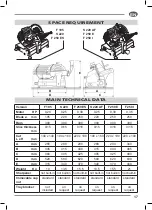

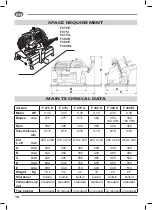

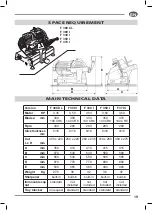

Page 53: ...F250I F275I F300E F275IL F300EL Ed 06 2016 51 F250I F275I F300E F275IL F300EL Ed 06 2016 EN...

Page 54: ...52 EN...

Page 55: ...Ed 06 2016 53 Ed 06 2016 EN...

Page 56: ...54 128 127 1 12 121 122 125 123 124 126 EN 125 123 124...

Page 58: ...56 127 126 122 125 123 124 121 90 EN 125 123 124...

Page 67: ...Notes...

Page 68: ......

Page 69: ...03 2019...