17

ENGLISH

ENGLISH

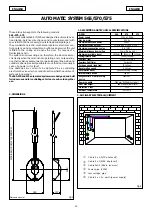

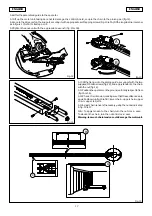

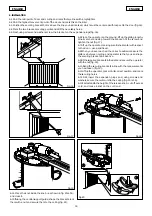

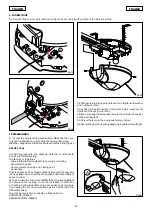

5.10 Fit the flange into the sliding guide, securing it with the two

supplied M5 Allen screws (fig.14), and apply tension to the chain

with the nut (fig.14).

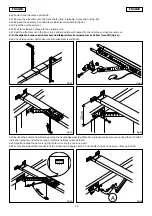

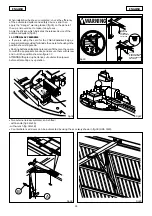

5.11 Position the operator on the ground, vertically respect to floor

(fig. 15 ref. A).

5.12 Check chain tension, making sure that these distances are

equal (as shown in fig. 15 ref. B) : lower chain - upper chain; upper

chain - upper rail joint.

5.13 Adjust chain tension if necessary, using the nut as indicated

in fig. 15 ref. C.

N.B. : To apply tension to the chain, turn the nut clock - wise.

To slacken the chain, turn the nut anti clock - wise

Warning: too much chain tension could damage the motor unit.

5.6 Offer the assembled guide to the operator.

5.7 Lift up the motor unit, taking care not to damage the control board, couple the chain to the pinion gear (fig.12).

5.8 Locate the drive unit on the support, securing it with appropriate self-tapping screws (Fig.13 ref.A).Fit the longitudinal member

as in figure 13 (ref.A) to its stop point.

5.9 Tighten the drive unit with the appropriate wrench (fig. 13 ref.B).

Fig.12

Fig.13

Fig.14

B

C

A

Fig.15

A

B

Summary of Contents for 565

Page 15: ......