23

ENGLISH

ENGLISH

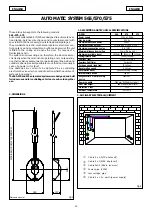

FUNCTION LOGICS

* Prevents closing if pulse is maintained

* Prevents closing and/or opening if pulse is maintained

Table 1 AUTOMATIC Logic

CLOSED

OPEN

CLOSING

LOCKED

OPENING

Closes

Open

Reverses motion

Locks

Closes

STOP

OPEN

SAFETY DEVICES

No effect**

Locks **

Locks **

No effect**

No effect

Reverses motion

No effect *

No effect *

OVERHEAD

DOOR

No effect**

No effect *

Table 2 SEMI-AUTOMATIC Logic

CLOSED

OPEN FOR

PAUSE

CLOSING

OPENING

Opens and

closes after the

pause time

Closes

STOP

OPEN

SAFETY DEVICES

No effect**

Locks *

Locks **

Locks **

No effect**

No effect

Restarts pause

time count*

Reverses motion

No effect *

No effect *

OVERHEAD

DOOR

LOCKED

Reverses motion

Restarts pause

time count*

No effect

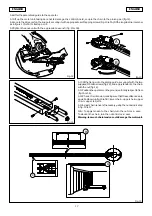

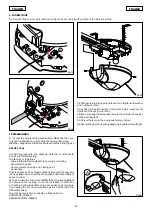

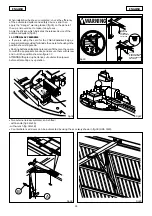

AUTOMATIC SET-UP

The set-up procedure is executed automatically just with a pulse.

MANUAL SET-UP

This procedure enables you to select the deceleration points, the

fully open point, and pause time.

AUTOMATIC SET-UP WITH LOGIC “E” (SEMI-AUTOMATIC)

Press and release the SET-UP push-button to select the logic.

After 8 seconds the operator effects a closing operation until a

stop is detected.

The operator now opens the door, and the opening movement

finishes when the mechanical stop is recognised.

The door is immediately closed.

The electronic appliance establishes the deceleration points.

If the SETUP procedure was

successful

, the courtesy lamp stays

lighted for 5 seconds. During this time, in order to reduce the load

on the release system, open pulses can be sent within 2 seconds

of each other to reverse the release carriage. A pulse equals

travel of 5 millimetres.

N.B.: the carriage can be seen to reverse only when the auto-

mated system is operating normally.

MANUAL SET-UP WITH LOGIC “E” (SEMI-AUTOMATIC)

Press and release the SET-UP push-button to select the logic.Carry

out the following procedure within 8 seconds after pressing the

SETUP push-button, otherwise the oprator will execute auto-

matic SETUP.

1

st

OPEN: the operator effects a closing operation until a stop is

detected.

2nd OPEN: the operator continues with an opening movement.

3rd OPEN: defines the point at which start of deceleration is

required.

4th OPEN: defines the end of the opening** movement.

5th OPEN: starts closing movement.

6th OPEN: defines the point at which start of deceleration is

required.

Allow the operator to reach the stop.

If the SETUP procedure was

successful

, the courtesy lamp stays

lighted for 5 seconds. During this time, in order to reduce the load

on the release system, open pulses can be sent within 2 seconds

of each other to reverse the release carriage. A pulse equals

travel of 5 millimetres.

N.B.: the carriage can be seen to reverse only when the auto-

mated system is operating normally.

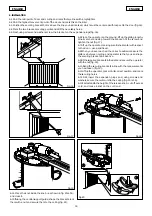

AUTOMATIC SET-UP WITH LOGIC “A” (AUTOMATIC)

Hold down the SET-UP push-button to select the logic until the

courtesy light goes on (about 5 seconds).

After 8 seconds the operator effects a closing operation until a

stop is detected.

The operator now opens the door, and the opening movement

finishes when the mechanical stop is recognised.*

The door is immediately closed.

The electronic appliance establishes the deceleration points,

and pause time is fixed at 3 minutes.

If the SETUP procedure was

successful

, the courtesy lamp stays

lighted for 5 seconds. During this time, in order to reduce the load

on the release system, open pulses can be sent within 2 seconds

of each other to reverse the release carriage. A pulse equals

travel of 5 millimetres.

N.B.: the carriage can be seen to reverse only when the auto-

mated system is operating normally.

MANUAL SET-UP WITH LOGIC “A” (AUTOMATIC)

Hold down the SET-UP push-button to select the logic until the

courtesy light goes on (about 5 seconds).Carry out the following

procedure within 8 seconds after pressing the SETUP push-button,

otherwise the oprator will execute automatic SETUP.

1

st

OPEN: the operator effects a closing operation until a stop is

detected.

2nd OPEN: the operator continues with an opening movement.

3rd OPEN: defines the point at which start of deceleration is

required.

4th OPEN: defines the end of the opening movement and starts

the pause time count** (3 minutes max.).

5th OPEN: interrupts the pause time count and starts the closing

movement.

6th OPEN: defines the point at which start of deceleration is

required.

Allow the operator to reach the stop.

If the SETUP procedure was

successful

, the courtesy lamp stays

lighted for 5 seconds. During this time, in order to reduce the load

on the release system, open pulses can be sent within 2 seconds

of each other to reverse the release carriage. A pulse equals travel

of 5 millimetres.

N.B.: the carriage can be seen to reverse only when the auto-

mated system is operating normally.

* Otherwise, an OPEN pulse may replace the stop.

** Otherwise, the stop can be used during opening.

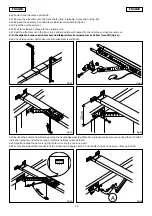

IMPORTANT: At set-up, if the operator does not effect any move-

ment when the OPEN push-button (see fig.34 ref. A) is pressed,

check that the housing is in correct position.

Summary of Contents for 565

Page 15: ......