The obstacle detection function is achieved by controlling the

current absorption and / or through the encoder connected to

the motors.

If the gate encounters an obstacle during the movement of

opening or closing, the obstacle detection function is activa-

ted and the operator reverses the direction of the gate.

In case of a second consecutive obstacle the operator stops

the gate right away and any further command is inhibited.

To re-enable the automation, you must remove power (and

disconnect batteries if present) or open the STOP contact input.

The Audio Alarm output will be active until this “reset”.

This is a more detailed description of what happens after an

obstacle detection:

Gate opening, obstacle detected:

Gate reverses partially (for 3 sec.) and STOPS. After that either

the gate is in a halfway position or completely closed

An open_A command is received:

the Gate tries to open from the current position:

If there is another obstacle detection:

complete stop, alarm goes off

If the gate reaches the open position:

obstructions count reset, return to normal operations

Gate closing, obstacle detected:

Gate reverses partially (for 3 sec.) and STOPS. After that either

the gate is in a halfway position or the gate is completely open

An open_A command is received:

In NON Automatic mode:

if the gate was not completely open:

execute

an

open

if the gate was completely open:

execute

a

close

in Automatic mode:

if the gate was not completely open:

execute an open, wait for the pause

time and then closes.

if the gate was completely open:

reload the pausetime, and then closes

If there is another obstacle detection:

complete stop, alarm goes off

If the gate reaches the close position:

obstructions count reset, return to normal operations

7. At the point where you want the slowdown to start give an

OPEN A command with the push button or the remote that

is already stored in memory. Leaf 2 starts to slow down and

stops when it reaches the mechanical stop or FCA2.

8. Leaf 2 starts to close at the set speed (trimmer speed).

9. At the point where you want the slowdown to start give an

OPEN A command with the push button or the remote that

is already stored in memory. The leaf 2 starts to slow down

and stops when it reaches the mechanical stop or FCC2.

10. Leaf 1 starts to close at the set speed (trimmer speed).

11. At the point where you want the slowdown to start give an

OPEN A command with the push button or the remote that

is already stored in memory. Leaf 1 starts to slow down and

stops when it reaches the mechanical stop or FCC1.

12. The manual time learning procedure is complete.

15

15/32

”

6 7/32”

17

15/32

”

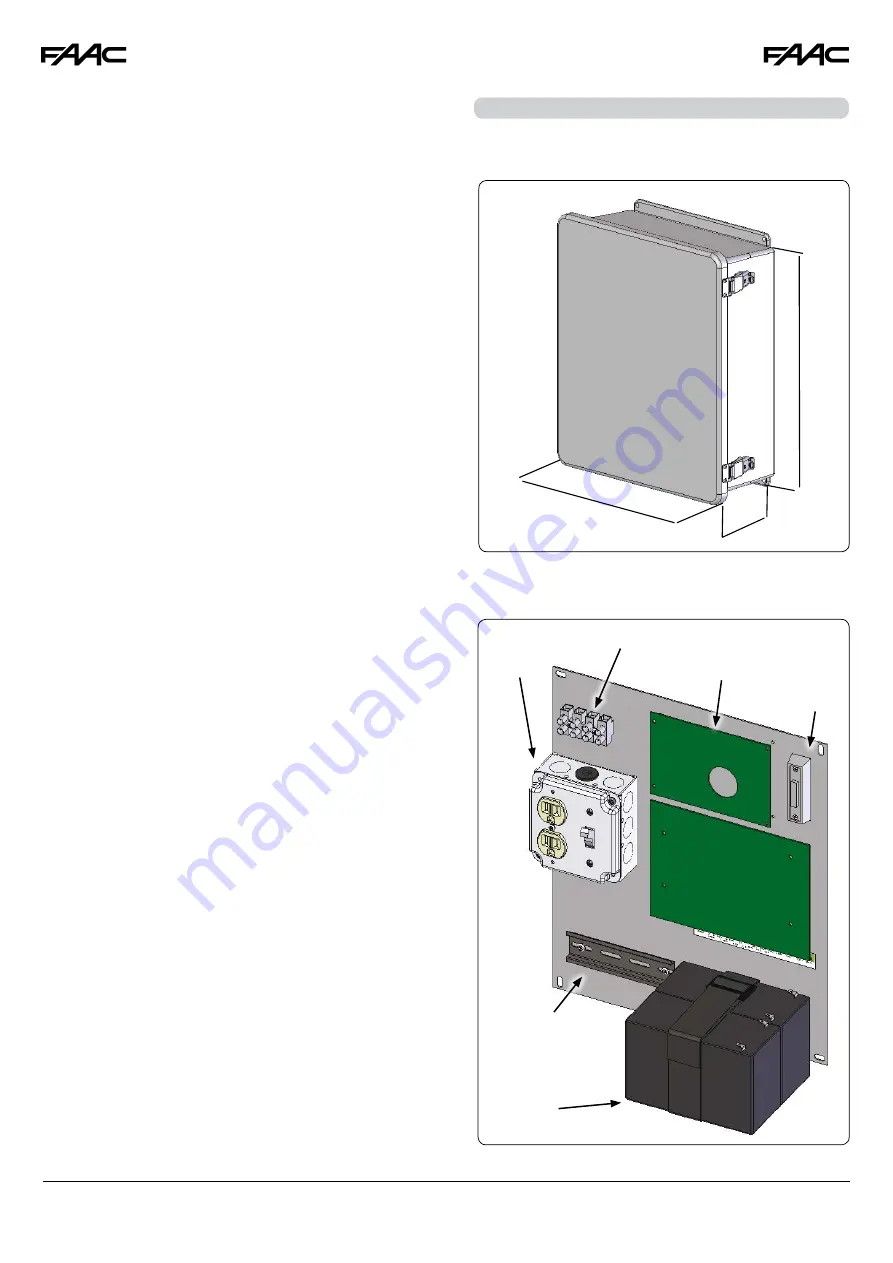

The E024U board is supplied on a panel that fits in a 16x14”

enclosure.

On the back panel there are: the control board, the power supply

and additional accessories.

Power Supply

AC connection

Power outlet

and switch

(optional)

Pushbutton

(optional)

E24U board

DIN rail

Batteries

6.3 OBSTACLE DETECTION FUNCTION

7. ENCLOSURE

A12