Model 42582 Version 6.0 Sept 2007

7

Automatic Datalogging Mode

Automatic Datalogging mode the Model 42580 can automatically measure and

store 12,000 readings at a programmed sample rate. Data saved in the Automatic

Datalogging mode can be recalled in the display, printed or transferred to a PC.

Press the

F3

LOG

softkey from the WELCOME display to access LOG screens 1 and 2:

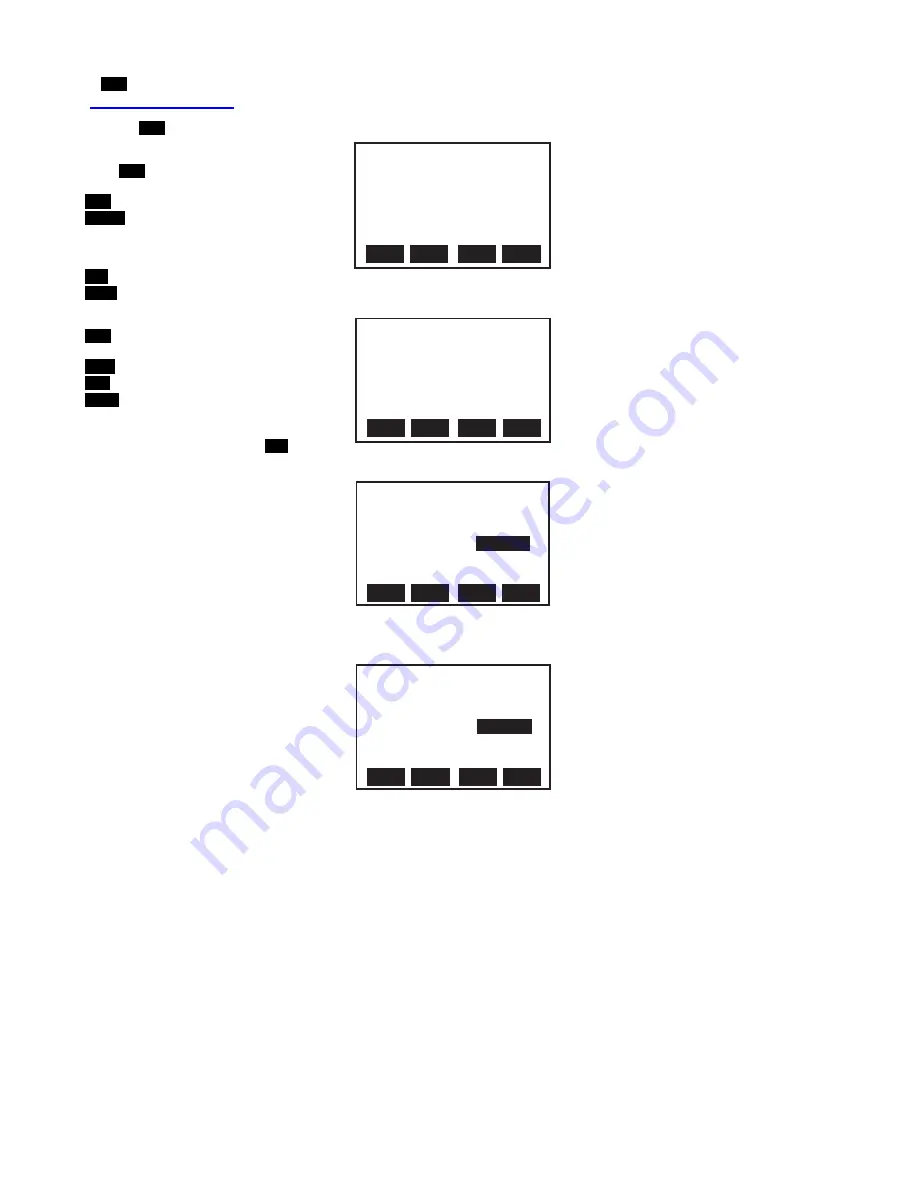

Log Screen 1

Press

F3

LOG

from the WELCOME screen to

access LOG SCREEN 1.

F1

EXIT

:

Return to the WELCOME screen

F2

START

:

Begin automatic Datalogging at the

pre-set sampling interval. Datalogging will

begin at the date/ time programmed in the

SETUP mode.

F3

SET

:

Setup mode.

F4

NEXT

:

Advances to LOG SCREEN 2:

Log Screen 2

F1

LOG

:

Previous Page (previous 100 stored

readings)

F2

N-PG

:

Next Page (next 100 stored readings)

F3

PRN

:

Print page

F4

BACK

:

Return to Log Screen 1

Automatic Datalogging SETUP mode

From LOG SCREEN 1, press the

F3

SET

button to

enter the configuration screen:

BEGIN:

Date when datalogging will automatically

begin

START:

Time of day that datalogging will begin

END:

Date when datalogging will end

SUSPEND

: Time of day that datalogging will stop

each day

RATE:

Sampling interval (time between recorded

readings)

EXPECT:

Total memory capacity (12,000)

REMAIN:

Memory locations remaining

The two SETUP screens are almost identical; only the softkeys are different (see

diagrams). The softkey functions for both SETUP

screens are as follows:

EXIT:

Returns to WELCOME screen.

EDIT:

Select display field for editing.

VIEW:

Calls up the stored readings log.

NEXT:

Switches to SETUP screen 2.

START:

Activates the datalogger

CLR:

Erases all readings stores in the automatic

datalogger memory.

PRN:

Prints the datalogger memory record

BACK:

Return to the SETUP screen 1.

00001:12-05

18:45:00

T: 82.0l F

o

EXIT

NEXT

START

LOG SCREEN 1

SET

00002:12-05

18:45:10

T: 82.0l F

o

00003:12-05

18:45:20

T: 82.0l F

o

00001:12-05

18:45:00

T: 82.0l F

o

P-PG

BACK

N-NP

LOG SCREEN 2

PRN

00002:12-05

18:45:10

T: 82.0l F

o

00003:12-05

18:45:20

T: 82.0l F

o

EXIT

NEXT

EDIT

AUTO DATALOGGER SETUP 1

VIEW

Begin:

01-01-05

Start:

00:00:01

End:

02-02-05

Suspend:

23:59:59

Rate:

Expect:

12000 Points

Remain:

11900 Points

15 secs

START

BACK

CLR

AUTO DATALOGGER SETUP 2

PRN

Begin:

01-01-05

Start:

00:00:01

End:

02-02-05

Suspend:

23:59:59

Rate:

Expect:

12000 Points

Remain:

11900 Points

15 secs