Maintenance

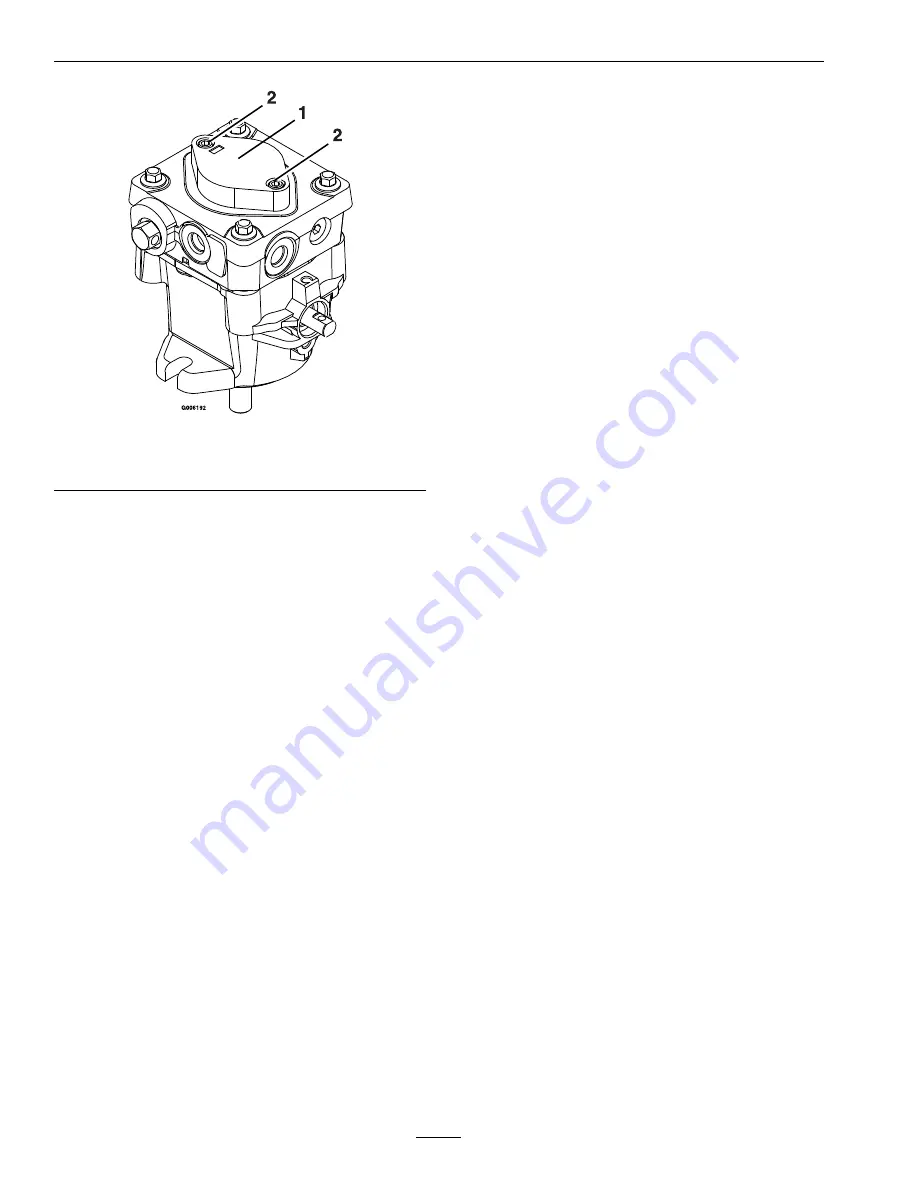

g006192

Figure 8

1.

Charge pump cap

2.

Loosen 1 1/2 turns only

1.

Stop engine and wait for all moving parts to stop.

Raise the rear of the machine up onto jack stands

high enough to raise the drive wheels off the

ground.

2.

Check oil level as stated in

Check Hydraulic Oil

Level

section.

3.

Start engine and move throttle control ahead to

full throttle position. Move the speed control

lever to the middle speed position and place the

drive levers in the “drive” position.

If either drive wheel does not rotate, it is possible

to assist the purging of the charge pump by

carefully rotating the tire in the forward position.

Note:

It is necessary to lightly touch the charge

pump cap with your hand to check the pump

temperature. If the cap is too hot to touch, turn

off engine. The pumps may be damaged if the

pump becomes too hot.

If either drive wheel still does not rotate continue

with step 4.

4.

Thoroughly clean the area around each of the

charge pump housings.

5.

To “prime” charge pump, loosen two hex socket

head capscrews (shown in Figure 8)

1 1/2 turns

only. Make sure engine is not running.

Lift

the charge pump housing upward and wait for

a steady flow of oil to flow out from under the

housing. Retighten the capscrews. Do this for

both pumps.

Note:

Hydraulic reservoir can be pressurized up

to 5 psi to speed this process.

6.

If either drive wheel still does not rotate, stop

and repeat steps 4 and 5 above for the respective

pump. If wheels rotate slowly, the system may

prime after additional running. Check oil level

as stated in

Check the Hydraulic Oil Level

section.

7.

Allow unit to run several minutes after the charge

pumps are “primed” with drive system in the full

speed position. Check oil level as stated in

Check

the Hydraulic Oil Level

section.

8.

Check hydro drive linkage adjustment as stated in

Hydro Drive Linkage Adjustment

section in

Adjustments.

Replace Emissions Air Intake

Filter

Service Interval: Every 500 hours

1.

Stop engine, wait for all moving parts to stop, and

remove key or spark plug wire(s). Engage parking

brake.

2.

Remove the filter from the vent hose.

3.

Insert a new filter into the end of the vent hose.

Thread Locking Adhesives

Thread locking adhesives such as “Loctite 242”

or “Fel-Pro, Pro-Lock Nut Type” are used on the

following fasteners:

•

Pump sheave setscrews.

•

Square head setscrews on hydro pump control

arms.

•

OPC lever setscrews.

•

Shoulder bolts in ends of speed control crank.

•

Sheave retaining bolt in end of engine crankshaft.

•

Fuel tank bulkhead fitting threads

Adhesives such as “Loctite RC/609 or RC/680” or

“Fel-Pro Pro-Lock Retaining I or Retaining II” are

used on the following:

•

OPC lever hubs and cross-shaft.

Note:

Care must be used not to bond the

bearing, next to each OPC hub, to the cross-shaft

30

Summary of Contents for VIKING 346

Page 1: ...VIKING For Serial Nos 408 644 346 Higher Part No 4505 182 Rev A ...

Page 45: ...Schematics g010189 45 ...

Page 47: ...47 ...