Maintenance

control arms to prevent the drive system from

stalling.

2.

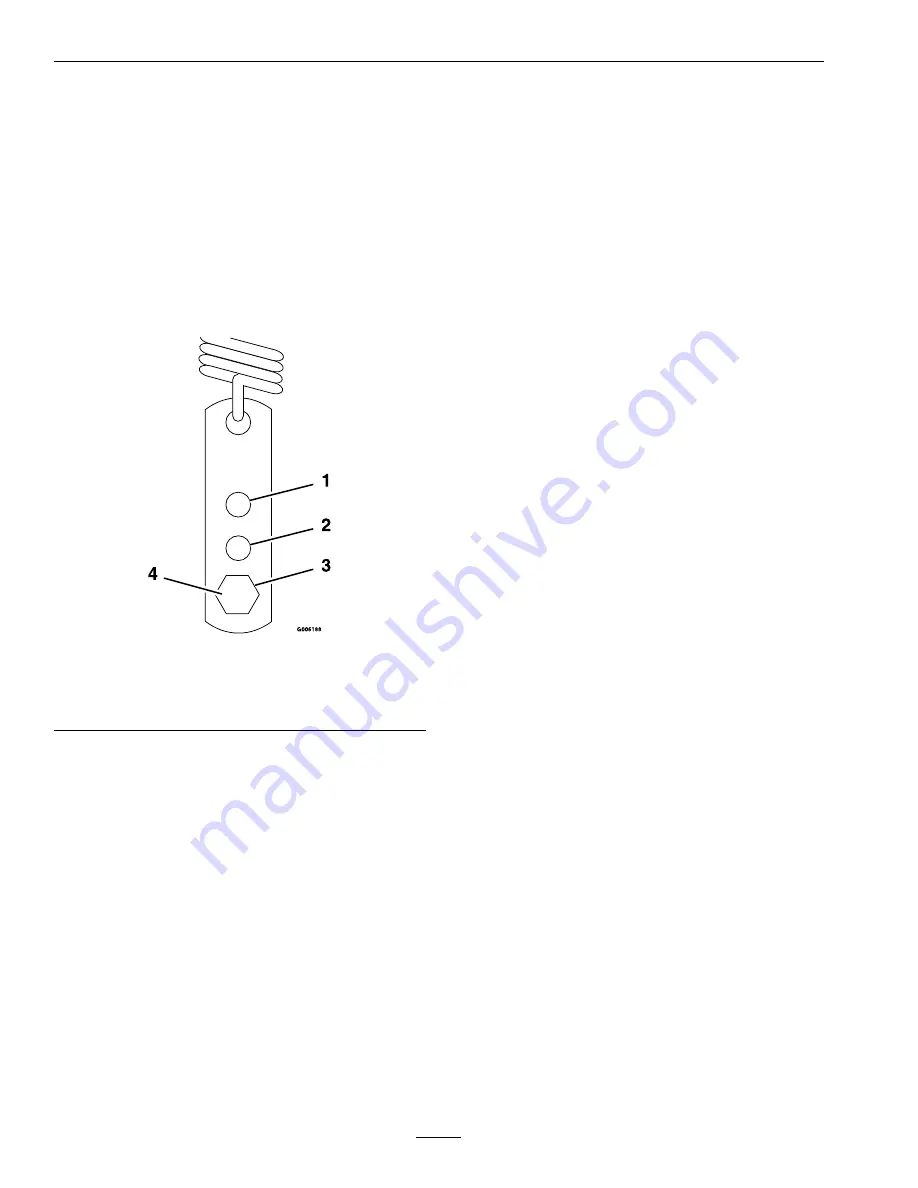

For a heavier drive setting, relocate the spring

anchor links to either the “medium” or “heavy

duty” positions as shown in Figure 23. The spring

anchor links are attached to the upper rear corner

of the hydro drive shields on the left and right

hand sides of the machine.

Note:

In the “medium” or “heavy duty”

positions, the drive lever forces at the upper

handle will also be increased.

g006188

Figure 23

1.

Heavy duty

3.

Standard

2.

Medium duty

4.

Retaining bolt

Park Brake Adjustment

1.

Stop engine and wait for all moving parts to stop.

2.

Disengage the park brake.

3.

Remove the hairpin in the lower park brake

linkage. Turn the linkage in the yoke until there is

3/16 inch (.48 cm) to 1/4 inch (.64 cm) clearance

between the park brake tire bars and the tires with

the park brake disengaged. Re-install the hairpin.

Cleaning

Cleaning and Storing Safety

•

Park machine on level ground, disengage drives,

set parking brake, stop engine, remove key,

and disconnect spark plug wire. Wait for all

moving parts to stop before leaving the operator’s

position. Allow the machine to cool before

servicing, adjusting, fueling, cleaning, or storing.

•

Clean grass and debris from the cutting unit,

muffler, drives, grass catcher, and engine

compartment to prevent fires.

•

Allow the machine to cool before storing the

machine in any enclosure. Do not store the

machine or fuel container, or refuel, where there

is an open flame, spark, or pilot light such as on a

water heater or other appliance.

Clean Debris From Machine

Service Interval: Before each use or daily

1.

Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

2.

Clean off any oil, debris, or grass build-up on the

machine and cutting deck, especially under deck

belt shields, around the fuel tank, around engine

and exhaust area.

Important:

You can wash the machine with

mild detergent and water. Do not pressure

wash the machine. Avoid excessive use of

water, especially near the control panel,

around the engine, hydraulic pumps, and

motors.

Clean Engine and Exhaust

System Area

Service Interval: Before each use or daily

(May be required more

often in dry or dirty

conditions.)

40

Summary of Contents for VIKING 346

Page 1: ...VIKING For Serial Nos 408 644 346 Higher Part No 4505 182 Rev A ...

Page 45: ...Schematics g010189 45 ...

Page 47: ...47 ...