Maintenance

Thread Locking Adhesives

Thread locking adhesives such as “Loctite 242”

or “Fel-Pro, Pro-Lock Nut Type” are used on the

following fasteners:

•

Pump sheave setscrews.

•

Sheave retaining bolt in end of engine crankshaft.

•

Caster wheel spacer nuts.

•

Platform spring pin.

Mobil HTS Grease (Or

Food-Grade Anti-seize)

Mobil HTS grease (or food-grade anti-seize) is used

in the following locations:

Between splines of the cutter housing spindle and

sheave.

Copper-Based Anti-seize

Copper-based anti-seize is used in the following

locations:

•

On threads of Blade Bolts. See

Check Mower

Blades

section.

•

Between engine crankshaft, pump drive sheave,

and clutch.

•

Between pump shafts and sheaves.

Dielectric Grease

Dielectric grease is used on all blade type electrical

connections to prevent corrosion and loss of contact.

Dielectric grease should not be applied to sealed

connectors.

Adjustments

Note:

Disengage PTO, shut off engine, wait for

all moving parts to stop, engage parking brake, and

remove key before servicing, cleaning, or making any

adjustments to the unit.

CAUTION

Raising the mower for service or maintenance

relying solely on mechanical or hydraulic

jacks could be dangerous. The mechanical or

hydraulic jacks may not be enough support or

may malfunction allowing the unit to fall, which

could cause injury.

Do Not rely solely on mechanical or hydraulic

jacks for support. Use adequate jack stands or

equivalent support.

Deck Leveling

Note:

Side to side deck leveling should be done by

an Authorized Service Dealer. Small adjustments can

be accomplished by increasing the tire pressure in the

tire on the low side.

1. Park the machine on a level surface and disengage

the blade control switch.

2. Stop engine, wait for all moving parts to stop, and

remove key. Engage parking brake.

3. Check the air pressure in the drive tires. If needed,

adjust to the recommended inflation; refer to

Checking the Tire Pressure

in Drive System

Maintenance section.

4. Set the height of cut lever to the 3 inch (7.6 cm)

position.

5. Raise the discharge deflector.

6. Carefully rotate the blades front to rear. Measure

from the tip of the front blade to the level surface

(Figure 19). The blades should measure 3 inches

(7.6 cm).

37

Summary of Contents for VANTAGE X Series

Page 1: ...VANTAGE X SERIES For Serial Nos 315 000 000 Higher Part No 4502 224 Rev A ...

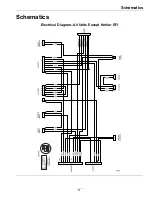

Page 51: ...Schematics Schematics Electrical Diagram All Units Except Kohler EFI 51 ...

Page 52: ...Schematics Electrical Diagram Kohler EFI 52 ...

Page 53: ...Schematics Electrical Schematic All Units Except Kohler EFI 53 ...

Page 54: ...Schematics Electrical Schematic Kohler EFI 54 ...

Page 55: ...Schematics Hydraulic Diagram 55 ...

Page 57: ...Service Record Date Description of Work Done Service Done By 57 ...

Page 58: ...58 ...