Page 10 of 13

109-4195 Rev. A

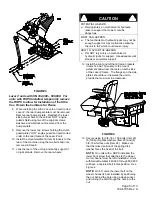

Align Dimple Here

mounting pin. The mount pin can be installed in

two positions. For 60” decks, SN 599,999 and

lower, the pin should be installed as far away from

the bumper end as possible. For all 72” decks

and 60” and 66” decks SN 600,000 and higher,

the pin should be installed close to the bumper

end (See Figure 13).

FIGURE 13

28. Install the belt (Item 13) onto the blower by

working it around the impeller sheave.

FIGURE 14

All units

:

29. Mount the blower on the deck by sliding the

mounting pin into the tube at the rear right corner

of the deck. Swing the blower closed. Adjust the

position of the front pin to engage the slot in the

front of the deck. Use the latch to lock the blower

in this position. Adjust the tension on the latch to

hold the blower up to the deck, yet allow for

release by hand.

30. Pull the spring loaded idler back and slip the

belt over the top deck spindle sheave.

31. Install the plastic belt cover (Item 10). On 60”

and 66” units the outside end of the cover is

slotted and can slip between the two washers

assembled in step 26. The plastic knob does

not need to be removed. On 72” units the

cover has a hole, and the plastic knob must

be installed after the cover has been

positioned.

On Units SN 600,000 and Higher with Triton

decks

:

32. Adjust dog leg baffle to match Ultra Vac

blower intake opening. Adjusting too wide

may allow objects to be thrown from under the

mower deck at high speed. Adjusting too

narrow may cause plugging issues.

WARNING

POTENTIAL HAZARD

♦

If the blower intake opening is not correct it

will allow objects to be thrown in operator’s or

bystander’s direction. Also, contact with blade

could occur.

WHAT CAN HAPPEN

♦

Thrown objects or blade contact can cause

serious injury or kill you or bystanders.

HOW TO AVOID THE HAZARD

♦

Adjust dog leg baffle to match intake opening.

Assemble the Tubes

1. Slip upper and lower tubes together.

2. Insert upper tube into hopper seal – push in

then pull out so that seal is extended outward.

Align dimple on upper tube with end of hopper

seal and position vertically between the two

screws as shown in Figure 15.

FIGURE 15