39

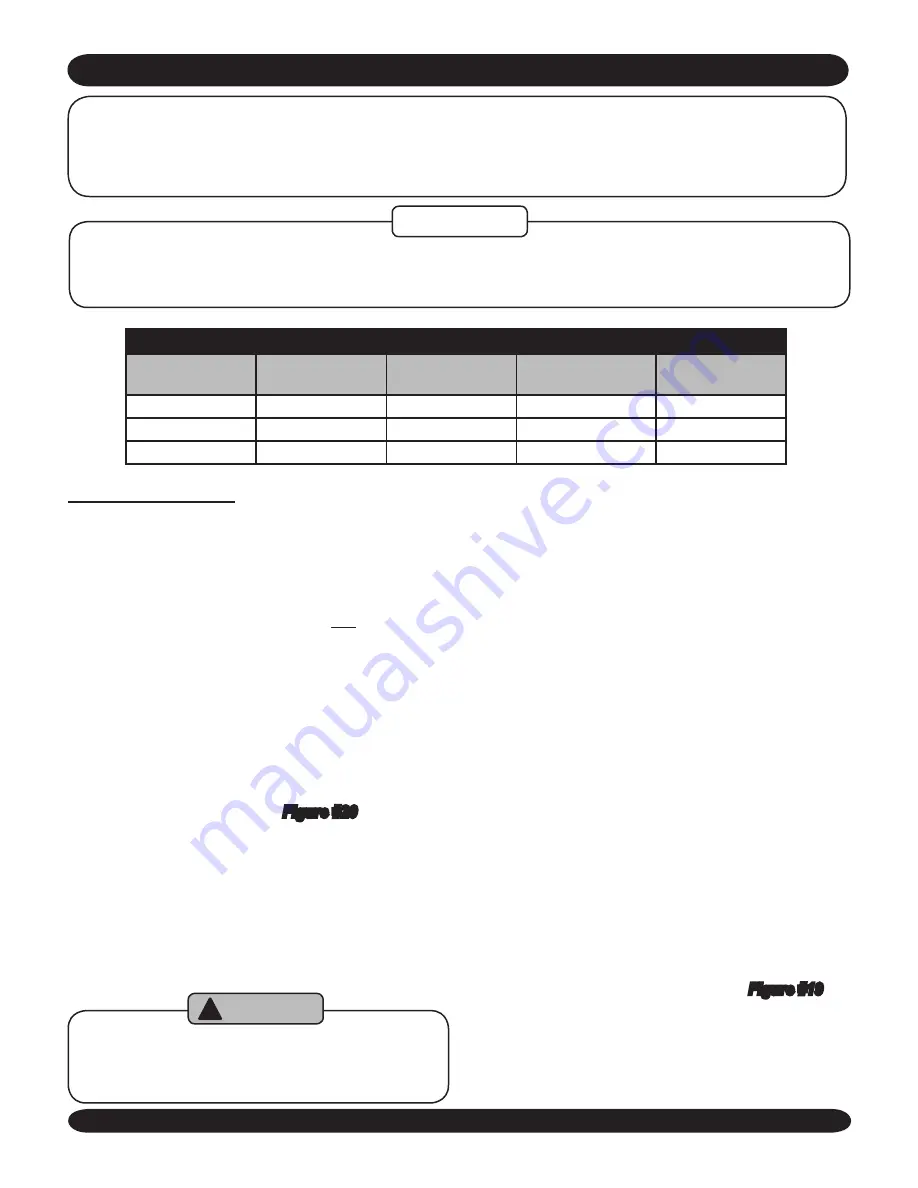

TABLe 8: ReCoMMended MiniMuM CHiMney siZes

FiRinG RATe

(gph)

CHiMney

HeiGHT

(ft)

noMinAL

CHiMney

rOunD

LinEr inSiDE

sQuARe

LinEr inSiDE

0.60 -1.30

15

8” x 8”

6”

6 ¾” x 6 ¾”

1.31 -1.80

15

8” x 8”

7”

6 ¾” x 6 ¾”

1.81 -2.00

20

8” x 8”

8”

6 ¾” x 6 ¾”

For elevations above 2,000 feet above sea level, add 3 feet to the chimney heights.

CHIMNEY AND CHIMNEY CONNECTIONS

For oil fired boilers with connections to vents or chimneys, vent installations shall be in accordance

with applicable provisions of nFPA31 insTALLATion oF oiL BuRninG eQuiPMenT, latest revision,

(u.s.) or CsA B139 (Canada) and applicable provisions of local building codes.

Fresh air (ventilation) is important to proper venting. Ventilation and venting are two parts of the same sys-

tem. Inadequate ventilation will result in inadequate venting. Always be sure to have enough ventilation to

ensure proper venting.

NOTICE

CHiMney VenTinG

Chimney venting is an important part of a safe and

1.

efficient oil fired appliance system. Requirements of

NFPA31 – Standard for the Installation of Oil-Burning

Equipment and NFPA 211 – Standard for Chimneys,

Fireplaces, Vents, and Solid Fuel-Burning Appliances

for installations in the United States and the require-

ments of CSA B139 – Installation Code for Oil-burn-

ing Equipment. (Installations in Canada) must be met.

Ensure that there is sufficient draft during the entire

2.

heating season to allow for the safe evacuation of flue

gasses.

The boiler can be vented into a fireclay

3.

tile-lined

masonry chimney constructed from type L vent or a

factory built chimney that complies with the type HT

requirements of UL103. See

Figure #20

for recom-

mended installation.

Chimney Inspection – Prior to the installation of any

4.

new or replacement fuel burning equipment the

chimney shall be inspected by a qualified installer.

The chimney shall be examined by a qualified person

in accordance with the requirements of NFPA 211,

Standard for Chimneys, Fireplaces, Vents, and Solid

Fuel Burning Appliances or CSA B139.

de-rating the appliance may cause conden

-

sation on the interior walls of the chimney

and the boiler.

WARNING

!

Loose Mortar – Loose mortar could be an indica-

A.

tion of prior history of condensing flue gases upon

the inside walls of the chimney. Colder climates are

more susceptible to this condition. Under no circum-

stances shall a chimney of this condition be used

until it meets the requirements of NFPA 211 or CSA

B139.

Unlined Chimney – Under no circumstances shall

B.

a chimney constructed of brick only be used. Only

approved clay liners or listed chimney lining systems

shall be used as specified in NFPA 31 or CSA B139

Abandoned Openings – Openings through the chim-

C.

ney wall that are no longer used shall be sealed in

accordance to NFPA 211. Often abandoned open-

ings are improperly sealed and usually covered by a

gypsum wall covering.

Clean Chimney – Chimney shall be free of all loose

D.

debris.

Install draft regulator at least 18” above breach. At

5.

least 18” of straight run up stream of regulator will

ensure proper operation.

Draft Regulator – the draft regulator supplied with the

6.

boiler must be used with this appliance. No other

draft regulator shall be used. Refer to

Figure #19

.