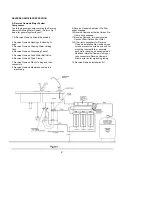

4. Reverse Osmosis Feed Water

Connection

– The Reverse Osmosis Feed

Water Ball Valve should be located as

close to the manifold assembly as

possible. USE A POTABLE COLD WATER

SUPPLY ONLY TO YOUR REVERSE

OSMOSIS SYSTEM. Softened water is

preferred as it will extend the life of the

Reverse Osmosis Membrane.

5. Reverse Osmosis Drain Connection

–

The Reverse Osmosis waste water must

go to a drain connection with easy access.

Do NOT connect the Reverse Osmosis

system drain line to the dishwasher drain

or near the garbage disposal.

2b. Drilling a porcelain sink:

It is best to use a special 1¼" diameter cutter

designed for porcelain. A carbide tipped

masonry bit is a second choice.

•

Place a piece of tape over the area to be

drilled to help prevent chipping.

•

Drill a pilot hole for the porcelain cutter. Use

the pilot drill supplied with the kit or a carbide

tipped drill.

•

When drilling the 1¼" hole, drill slowly and

carefully; the porcelain chips easily.

•

After drilling, clean the area well. Iron fillings,

if left in place, can cause rust stains.

REVERSE OSMOSIS INSTALLATION

STEPS

All plumbing should be done in accordance

with local plumbing codes.

In restricted under-sink areas, it may be easier

to install the Reverse Osmosis faucet first.

Allow adequate Reverse Osmosis tubing

lengths for any final Reverse Osmosis

component position.

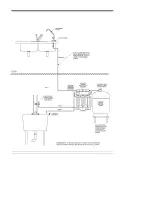

A. Reverse Osmosis Faucet Installation

2a. Drilling a stainless steel sink:

•

Center punch the hole to provide a

starting point for the drill.

•

Start with a smaller drill as a pilot, and

then drill a ½" diameter hole to accept

the bolt of a 1¼ " Greenlee Hole Punch

(1¼" chassis punch).

•

Clean away any chips.

•

Install the punch and tighten the nut to

cut the hole.

•

Deburr any sharp edges.

2c. Drilling a counter top:

NOTE:

The counter top must be less than 1¼"

thick. Treat ceramic tiles as porcelain until the

tile is penetrated, then use the carbide tipped

metal cutter.

Formica counter tops may be drilled with a good

1 ¼" wood bit, drilling a 3/32" pilot hole will help

keep the bit going straight.

IMPORTANT NOTICES:

This Reverse Osmosis system contains replaceable treatment components critical for effective performance. It is the user's responsibility to,

and the manufacturer strongly recommends that the user periodically test the Reverse Osmosis product water to verify the Reverse

Osmosis system is performing satisfactorily.

The Reverse Osmosis system is acceptable for water treatment of influent concentrations of no more that 27 mg/l nitrate and 3 mg/l nitrate

in combination measured as N and is certified for nitrate/nitrite reduction only for water supplies with a pressure of 40 psig (280 kPa) or

greater.

DO NOT USE WITH WATER THAT IS MICROBIOLOGICALLY UNSAFE OR OF UNKNOWN QUALITY, WITHOUT ADEQUATE

DISINFECTION BEFORE OR AFTER THE SYSTEM.

Reverse Osmosis Systems certified for cyst reduction may be used on disinfected

water that may contain filterable cysts.

5

Summary of Contents for EWR 4050

Page 5: ...BALL...

Page 8: ...LONG REACH FAUCET Figure 2A 6...

Page 14: ...12...

Page 15: ...13...

Page 16: ...14...

Page 17: ...15...

Page 18: ...16...

Page 19: ...17...

Page 20: ...18...

Page 23: ...21 Formatted Bottom 0 5...