REVERSE OSMOSIS OPERATION &

MAINTENANCE

A. Reverse Osmosis Normal Operation

1. Reverse Osmosis systems produce

drinking water at relatively slow rates.

Normal operation is to let the Reverse

Osmosis Holding Tank fill with water and

then draw water as is needed. When the

pressure in the Reverse Osmosis Holding

Tank falls to a given pressure (as the water

is being used) the Automatic Shut-Off

Valve (ASO Valve) will start water

production and the Reverse Osmosis

system will refill the Re4verse Osmosis

Holding Tank. When the Reverse Osmosis

Holding Tank is full and no water is being

used, the ASO Valve will automatically shut

off the feed water to conserve water. The

more water that is used (up to the capacity

of the system) the better the Reverse

Osmosis system will function.

After periods of non-use, such as a week

of vacation, it is better to empty the

Reverse Osmosis Holding Tank and allow

the Reverse Osmosis system to produce

fresh water for use. If the Reverse

Osmosis system is not used for 3-4 weeks

or longer, it is a good idea to re-sanitize the

Reverse Osmosis system and to change

the Reverse Osmosis pre-filter and post

filters.

B. Reverse Osmosis Changing Filters

THIS REVERSE OSMOSIS SYSTEM

CONTAINS REVERSE OSMOSIS FILTERS

WHICH MUST BE REPLACED AT

REGULAR INTERVALS TO MAINTAIN

PROPER PERFORMANCE. USE ONLY

FACTORY APPROVED FILTERS.

The recommended interval for changing the

Reverse Osmosis filters (not the Reverse

Osmosis Membrane) is every six (6) months.

Typical T.F.C. Reverse Osmosis Membrane

life expectancy is Five to ten years with

Water Softener prior to Reverse Osmosis

system. Local conditions may dictate more

frequent changes.

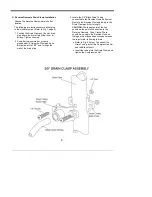

1. Close the Reverse Osmosis Feed Water Ball

Valve by turning fully clockwise and open the

Re4verse Osmosis Dispensing Faucet by

lifting the handle. Allow the REverse

Osmosis Holding Tank to empty.

2. Loosen and remove the Reverse Osmosis

Sediment Pre-filter and the Activated Carbon

Pre-filter Housings. Wash the inside of the

Reverse Osmosis Housings using a mild

detergent and a soft cloth. Do not use

abrasive cleaners or pads. Thoroughly rinse

all soap from the Reverse Osmosis

Housings before reassembly.

3. To sanitize the Reverse Osmosis system

and replace the Reverse Osmosis filters:

NOTE:

The Reverse Osmosis system should

be sanitized before installing the Reverse

Osmosis Activated Carbon Pre-filter.

•

Use a good quality unscented liquid

chlorine household bleach.

•

Add one capful Reverse Osmosis

Sediment Pre-filter Housing and install the

Reverse Osmosis Housing O-ring for

proper position in its groove, engage and

firmly tighten the Housing hand tight only.

•

Add one capful of bleach to the

Reverse Osmosis Activated Carbon Pre-

filter Housing. Install the Reverse Osmosis

Housing without the Reverse Osmosis

Activated Carbon Pre-filter.

•

The Reverse Osmosis Dispensing Faucet

should be open, slowly open the Reverse

Osmosis Feed Water Ball Valve.

•

As soon as the water begins to drip out of

the Dispensing Faucet, close the Faucet.

•

Let the Reverse Osmosis system stand for

15 minutes.

•

At the end of 15 minutes, in the following

order, close the Reverse Osmosis Feed

Water Ball Valve, close the Reverse

Osmosis Holding Tank Valve and open the

Dispensing Faucet to release the pressure.

•

Remove the Reverse Osmosis Activated

Carbon Pre-filter Housing and empty.

Remove the wrapping and install the

Reverse Osmosis Activated Carbon Pre-

filter. Firmly tighten the Reverse Osmosis

Housing hand tight only.

•

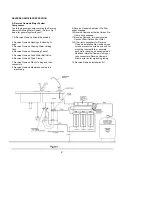

Disconnect the Reverse Osmosis tubing

that runs from the Reverse Osmosis

Holding Tank to the Tee (see Fig. 1, page

3). Put 50 drops of bleach (this is ½ tsp. or

10

Summary of Contents for EWR 4050

Page 5: ...BALL...

Page 8: ...LONG REACH FAUCET Figure 2A 6...

Page 14: ...12...

Page 15: ...13...

Page 16: ...14...

Page 17: ...15...

Page 18: ...16...

Page 19: ...17...

Page 20: ...18...

Page 23: ...21 Formatted Bottom 0 5...