3 ml) into the Reverse Osmosis tubing and

reconnect it to the Tee.

NOTE:

Now is the convenient time to

change the In-Line Reverse Osmosis

Activated Carbon Post Filter.

•

Slowly open the Reverse Osmosis Feed

Water Ball Valve. When water begins

dripping out of the Reverse Osmosis

Dispensing Faucet, in the following order,

close the Faucet and then open the Holding

Tank Valve.

•

Do not open the Reverse Osmosis Faucet

for at least 5 hours.

•

Discard the first three full tanks of water

produced, they will contain chlorine.

5. Slowly open the Reverse Osmosis Feed

Water Ball Valve.

6. When water begins dripping out of the

Reverse Osmosis Faucet, in the

following order, close the Reverse

Osmosis Faucet and open the Reverse

Osmosis Holding Tank Valve. When the

Reverse Osmosis Faucet is first

opened, expect air and carbon fines

(very fine black powder), from the new

Reverse Osmosis Post Filter to be

rinsed out. This is normal for the first

tank of water.

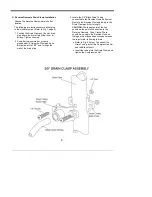

C. Changing the In-Line Reverse Osmosis

Activated Carbon Post Filter

1. Close the Reverse Osmosis Feed Water

Ball Valve by turning fully clockwise.

2. Close the Reverse Osmosis Holding Tank

Valve and then open the Reverse Osmosis

Dispensing Faucet to release the pressure.

3.

Remove the In-Line Reverse Osmosis

Activated Carbon Post Filter. Disconnect

the used Reverse Osmosis Post Filter by

pressing in the connector's collar and at the

same time pulling the tube out of the fitting.

Unscrew the fittings on the In-Line, re-

Teflon tape them and install them on the

new Reverse Osmosis Post Filter. Do not

over tighten the fittings.

4.

Firmly reconnect the polytubes to the new

Post Filter. (Refer to Fig. 5 below.)

REVERSE OSMOSIS TECHNICAL DATA

A. Reverse Osmosis Water Quality

Reverse Osmosis water quality is normally

measured with a TDS meter. The more

dissolved solids in the water, the higher the

conductivity. The results are usually

reported in

Parts per Million

(ppm) or

Milligrams per Liter

(mg/l) of

Total

Dissolved Solids

(TDS). (Although

technically they are not exactly equal, in

most discussions ppm = mg/l).

Reverse Osmosis Membranes are rated by

the amount of dissolved solids that are

rejected. This rating is a ration of the TDS in

the feed water to the TDS in the product

water and is reported as

Percent

Rejection

. If the feed water contained 100

ppm of TDS and the product water

contained 10 ppm of TDS, 90 ppm have

been rejected and the reject ration is 90%.

Percent Rejection =

Feed TDS – Product TDS

Feed TDS

EXAMPLE: Feed water is 500 ppm TDS

and the product water is 75 ppm TDS.

Percent Rejection = 500 – 75 x 100%

500

Percent Rejection = 0.85 x 100% or 85%

Figure 5

IN-LINE REVERSE OSMOSIS

COCONUT SHELL CARBON POST

FILTER ASSEMBLY

In-line Coconut Shell

Carbon Post Filter

IN

OUT

From

tank

To Faucet

11

Summary of Contents for EWR 4050

Page 5: ...BALL...

Page 8: ...LONG REACH FAUCET Figure 2A 6...

Page 14: ...12...

Page 15: ...13...

Page 16: ...14...

Page 17: ...15...

Page 18: ...16...

Page 19: ...17...

Page 20: ...18...

Page 23: ...21 Formatted Bottom 0 5...