Functional characteristics

TIG welding

58

099-00L200-EW501

13.05.2022

5.1.12.2 Responsiveness

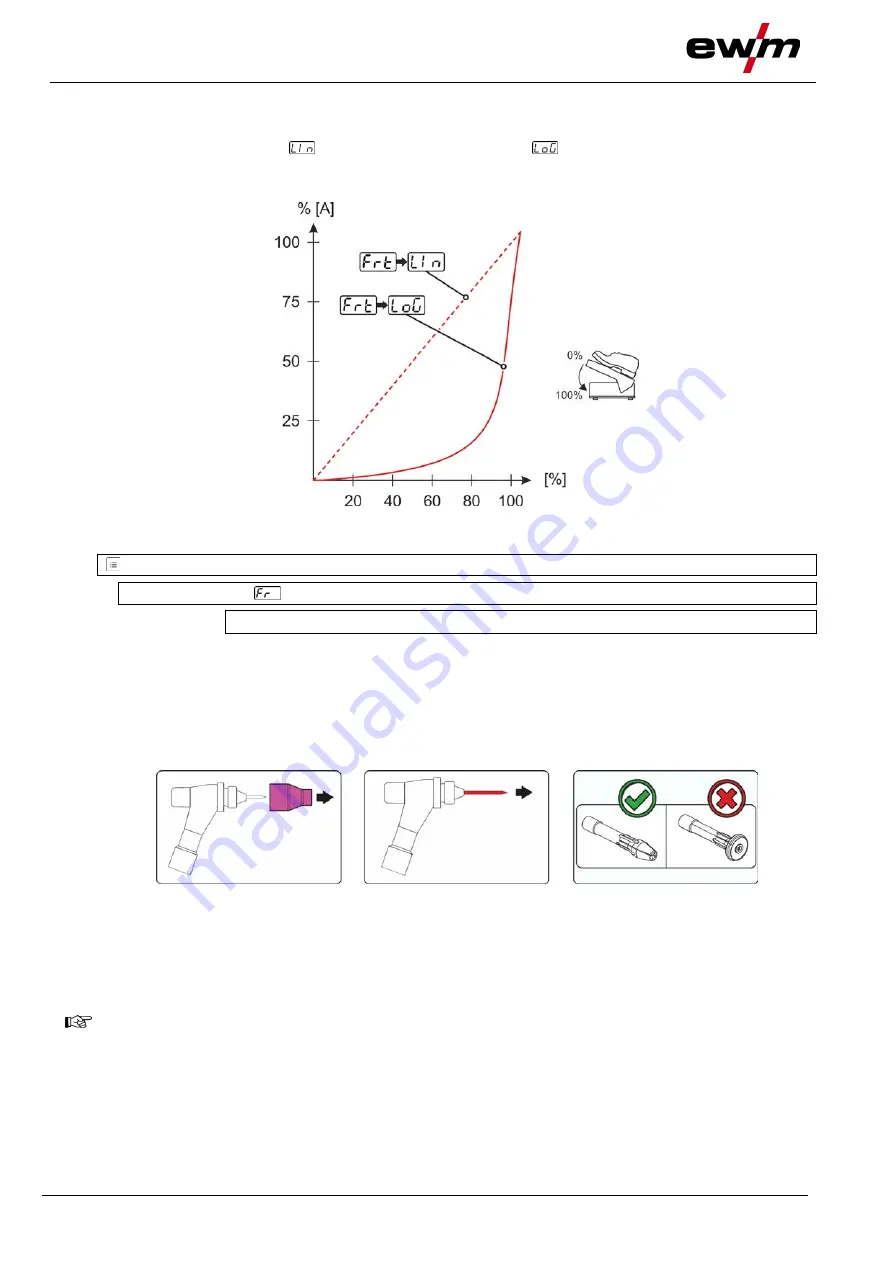

This function controls the responsiveness of the welding current during the main current phase. The user

can choose between linear

and logarithmic responsiveness

(factory setting). The logarithmic set-

ting is especially suited for welding with low current, for example for thin sheet metal. This method ena-

bles better dosing of the welding current.

Figure 5-35

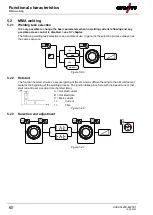

Selection

System settings

Remote control

Responsiveness

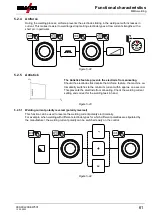

5.1.13 Aligning the cable resistance

To ensure optimum welding properties, the electric cable resistance should be aligned again whenever an

accessory component such as the welding torch or the intermediate hose package (AW) has been

changed. The resistance value of the cables can be set directly or can be aligned by the power source. In

the delivery state the cable resistance is set to the optimum values. To optimise the welding properties for

other cable lengths, an alignment process (voltage correction) is necessary.

Figure 5-36

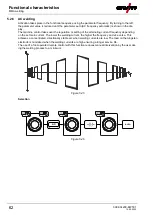

• Switch off the welding machine.

• Unscrew the gas nozzle from the welding torch.

• Unfasten the tungsten electrode and extract.

• Switch on the welding machine.

Material damage due to unsuitable torch equipment. Gas diffusors may not be used to take

measurements. Only electrode holders may be used to take measurements.