Section 5

Hardee by EVH

Maintenance

LR50148 Long Reach Mower

17

CAUTION

Never vary from the 2700-psi mowerhead pressure.

Failure to comply with this specification will cause

severe hydraulic heat, loss of power and damage to

components.

DANGER

Exceeding 2700 psi will cause premature hose failure

(rupture), and possible bodily injury or property

damage.

Cylinder Speeds

The LR50148 is equipped with a “Proportional

Control” feature in the main control valve that allows

the operator to control the piston speed of individual

cylinders with the amount of movement on the thumb

actuated joysticks.

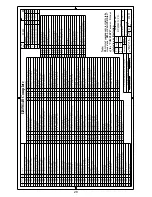

Adjusting the Cylinder Control Valve

The LR50148 comes from the factory with the cylinder

control valve pre-set at the proper pressures. There is

a main relief (Item P), and seven individual cylinder

counterbalance valves (Items 5D2; 5D1; 5C2; 5C1;

5B2; 5B1; 8A2; 8A1).

The chart on page 18 lists the

proper settings for these valves.

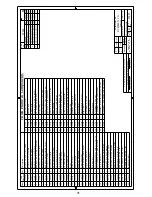

The procedure for checking the pressures on the

cylinder control valve is as follows:

Cylinder Relief Valve (ITEM P)

Rest the deck of the LR50148 on the ground to

relieve all pressures on the hydraulic lines.

With the tractor engine off and parking brake set,

remove the hydraulic test port plug

(see page 19

for gauge port locations)

. Install a 5000 psi

pressure gauge with a SAE 4-M-ORB fitting into

the hydraulic test port and place the gauge where

you can easily see it from a safe distance.

Start the tractor and bring the engine up to

operating speed 800 (Max.1000) PTO RPM.

Activate the joystick, raise the mower deck off the

ground, and swing the boom so that it is straight

behind the tractor.

Activate the joystick in the “HEAD UP” position

until the deck cylinder fully retracts. Continue to

hold the joystick in this position for not more than

5 seconds at a time, and have someone read the

pressure on the gauge.

WARNING

While reading the gauge, be careful not to stand in an

area where inadvertent movement of the booms could

trap or crush you. If you fail to heed this warning,

SERIOUS INJURY OR DEATH COULD OCCUR

.

The correct pressure setting for the cylinder relief is

2500 psi.

To increase or decrease pressure, insert a 1/4” allen-

wrench into the adjusting stem at the top of the valve.

Loosen the 3/4” lock nut at the base of the stem

slightly, and then turn the adjusting stem to make your

pressure change. Re-tighten the stem lock nut

Note:

The allen-head adjusting stem increases

pressure when turned clockwise and decreases

pressure when turned counterclockwise. Pressure

increases or decreases rapidly with only a slight

movement. Move adjusting stem in increments of 1/4

turn or less.

CAUTION

NEVER attempt to adjust the valve when in the “on”

(loaded) position. Always make adjustments in the

“off” (neutral) position with the tractor engine turned

off.

When 2500 psi is obtained, retighten the jam nut.

Then re-test the pressure to be sure 2500 psi is

retained.

When the adjustment is complete, rest the cutter

deck back on the ground to relieve pressure in the

hydraulic lines. Remove the pressure gauge and

re-install the hydraulic test port plug.

Individual Cylinder Counterbalance Valves

(

5D2;

5D1; 5C2; 5C1; 5B2; 5B1; 8A2; 8A1;)

Each cylinder has counterbalance valves that provide

both work port relief and load control. These valves

are 100% inspected and pre-set from the factory to

ensure the proper settings. Do not alter the settings on

these valves.

If you need assistance, contact your local Hardee

dealer.

Summary of Contents for HARDEE LR50148

Page 29: ...26...

Page 30: ...Section 6 Hardee by EVH Troubleshooting LR50148 Long Reach Mower 27...

Page 43: ...40...

Page 44: ...41...

Page 45: ...42...

Page 46: ...43...

Page 47: ...44...

Page 49: ...46 Section 8 Replacement Parts...

Page 50: ...6857 6 27 18 47...

Page 55: ...NOTES...