5

cartrIdge InStallatIon and actIVatIon

Remove the outer shrink-wrap and protective cap from the

1.

2SR-BW & MR-600 RO cartridges. Position a bucket under the

2SR -BW cartridge head. Slowly open the Inlet shut-off valve.

Apply power to the system by plugging the power cord into the

receptacle. Within moments, the display water should illuminate

and the system will go into PRESSURIZE mode. Once a solid flow

of water has been established, flush 1 gallon. Unplug power cord.

Empty bucket.

Install 2SR-BW cartridge. Align the lugs on the new cartridge

2.

with the slots in the head. Holding the head and cartridge firmly,

press the cartridge upward into the head fully, and then turn the

cartridge to the right until it stops.

Disconnect 3/8" OD line from 2SR-BW to Booster Pump inlet at

3.

Booster Pump. Route line into bucket and secure. Plug-in power

cord. Once a solid flow of water has been established, flush 1

gallon. Unplug power cord. Re-connect 3/8" OD line to Booster

Pump inlet. Empty bucket.

Route a blue line from the 3/8" storage tank drain valve to drain

4.

temporarily. Open storage tank drain valve.

Install MR-600 cartridge. Align the lugs on the new cartridge

5.

with the slots in the head. Holding the head and cartridge firmly,

press the cartridge upward into the head fully, and then turn the

cartridge to the right until it stops.

Plug-in power cord. Once a solid flow of water has been

6.

established, flush 5 gallons from storage tank drain (about 10

minutes). Unplug power cord.

WARNING

do not uSe tHIS Product Water! It may contain

a preservative solution from the ro cartridge and

should not be consumed!

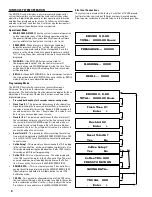

recoVery adjuStment

Measure the raw water TDS. Refer to Table 1 on page 6. Find

1.

the TDS range in the column labeled “Raw Water TDS” that

corresponds to your TDS measurement. Read across that row

to determine maximum recovery, permeate to reject ratio and

permeate/reject volumes.

Using 2 - 32 oz. or 1,000 ml graduated containers, apply power

2.

to the system and collect the permeate flow (from storage tank

drain valve) in one container and the reject (WASTE) flow in the

second container. Compare the volumes collected to the data

shown in the table. Adjust the reject needle valve to increase or

decrease the flow. Empty the containers and collect additional

samples.

Once the ratio of Permeate-to-Reject closely matches the data

3.

in Table 1, the Reject Only volume requires measurement. Using

only 1 graduated cylinder, collect the reject flow for 1 minute.

note:

Reject volume in 1 minute may exceed 32 oz./1,000 ml. If

so, use a larger container, or collect samples in multiple

containers and add all collected volumes together.

Unplug power cord. Close storage tank drain valve.

4.

Return to page 6, Table 2. Find the volume range in the column

5.

labeled “Reject Volume per Minute” that corresponds to the

volume collected in Step 4. Read across that row to identify the

correct capillary tube combination.

Locate the correct capillary tubes from the parts kit. Remove the

6.

2 - 1/4"OD tubes from the upper Y-connector. Insert the capillary

tubes into each line and re-assemble to the Y-connector.

note:

In some cases, the capillary tube requires trimming. Use a

SHARP utility knife to cut the tube cleanly without tearing or

crushing the tube.

Remove Reject Needle valve assembly and reconnect 3/8" tube.

7.

Plug-in power cord. Allow system to run and fill tank. This will

take 5-10 minutes.

Refer to Table 2 again. Under the column labeled “Flush Time in

8.

Seconds”, find the value that corresponds to the Raw Water TDS.

Enter this value in the controller under “FLUSH TIME X1”. Adjust

“FLUSH INT X2” to 1.5 Hours.

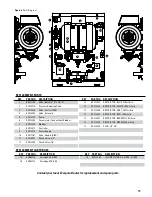

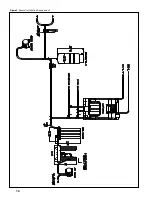

figure 5.

RO Reject Flow Control Assembly

TUBE

FLOW

CONTROL

Capillary

Not Trimmed

TUBE

FLOW

CONTROL

Capillary

Trimmed