24

ENGLISH

CHAPTER 14 TRANSPORT AND HANDLING

The transport and handling of the blast chiller must only be done while maintaining the vertical

position, observing the markings on the packaging.

The manufacturer disclaims any liability for problems resulting from transport performed under

conditions other than those specified above.

The accessories of the blast chiller (guides, grilles, trays) are packaged separately and placed inside

the blast chiller.

The blast chiller is mounted on a wooden base and protected from accidental impact with polyethylene,

carton, crate or boxes.

Regarding the disposal of the packaging it is necessary to refer to current regulations in your country.

The movement of the blast chiller shall be performed using a fork lift or pallet trucks equipped

with suitable forks (length of at least 2/3 of the blast chiller).

The dimensions and masses of the refrigerated cabinets packed are shown in Table 1.

The limits of stackability and the centre of gravity are indicated on the label of the package.

14.1 Positioning operations

Since the incorrect positioning of the blast chiller can cause damage to the same, jeopardizing its proper

functioning and result in risk to the personnel, the installer must adhere to the following general rules:

- position the blast chiller keeping minimum 3 cm distance from any wall and 50 cm from ceiling

- the environment must be sufficiently ventilated

- position the blast chiller away from heat sources

- avoid exposure to direct sunlight

- remove the polyethylene, cardboard or wood packaging

Polyethylene is dangerous for children

- remove any accessories with external connections

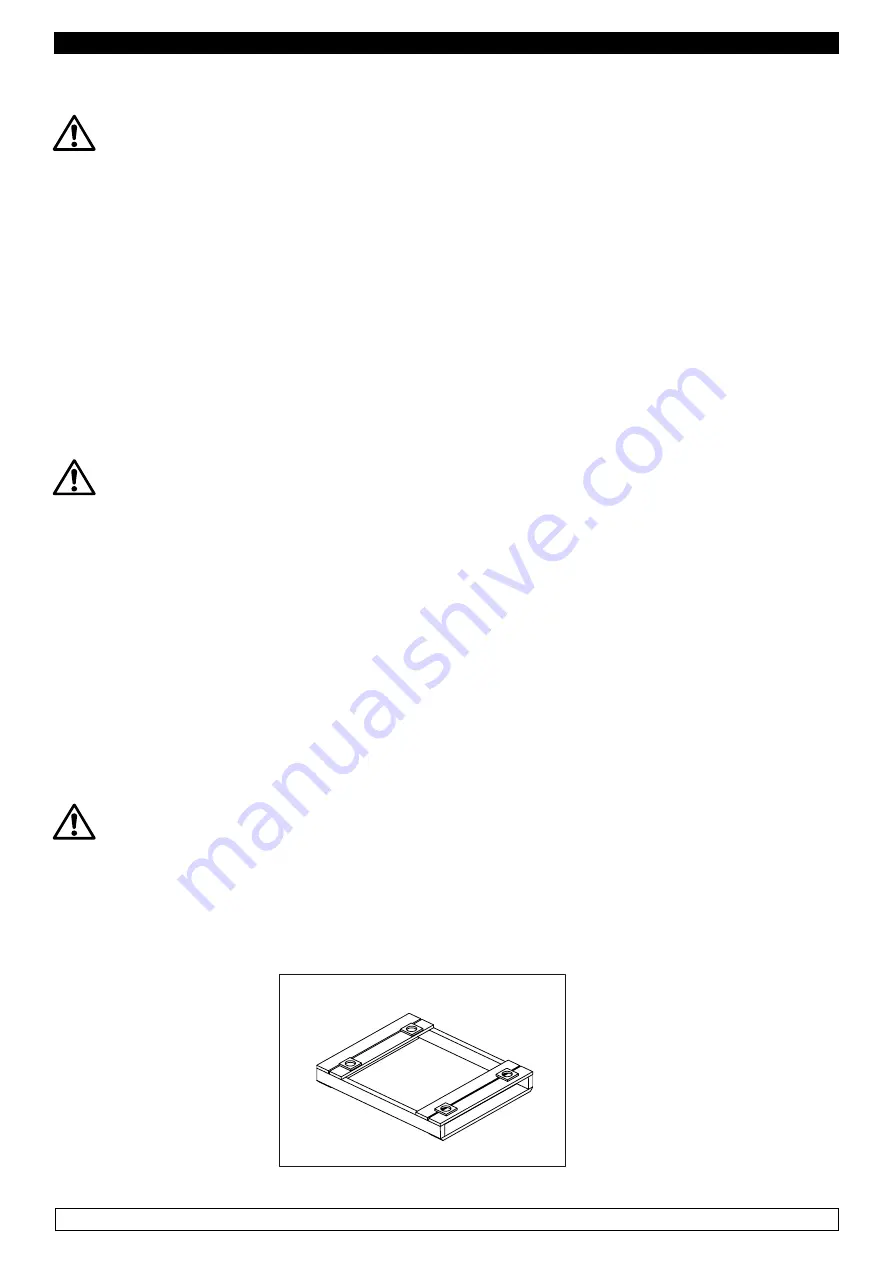

Removing the wooden base (Fig.4): lift the blast chiller and remove the base.

Fig.4