Hold the spinner in place using adhesive tape or clamps then, with some form of reference pointer

positioned close to the spinner about 10 - 15cm (4"-6") back from the front, carefully

(with ignition

off - note that if the ignition leads have not yet been wired to switches the ignition will be live!)

rotate the propeller by hand to check for concentricity. Removal of a spark plug from each cylinder

will make turning the propeller easier.

Adjust the spinner as required to achieve concentricity then mark out and drill nine 4.8mm holes,

three equally spaced between each blade, through the spinner and the rear bulkhead flange.

Remove the spinner and install MS21047-3 anchor nuts onto the inside of the rear bulkhead’s flange

using TAPK 33 BS countersink rivets.

Measure accurately the distance from the rear bulkhead’s rear flange to the radial centre line for the

front bulkhead screws.

Mark a line around the spinner for the front screw radial centre line then mark off six equally spaced

centres around the circumference.

Drill through both the spinner and the front bulkhead flange with a 4.8mm drill at the six centres, then

install MS21047-3 anchor nuts to the bulkhead using TAPK 33 BS rivets.

The spinner is now ready for installation with screws; however, the propeller pitch must be set

beforehand.

Propeller pitch

The relationship between propeller pitch and aircraft performance is something which will vary

slightly between aircraft, so a certain amount of experimentation will be required to establish

individual aircraft performance figures.

Also, individual requirements, such as runway length available, will influence the final propeller

setting used.

It is suggested that you set the propeller to 21° pitch angle initially. The blade angle referred to is the

angle between the propeller’s rotational plane and the flat rear surface of the blade at the propeller

tip.

Make any subsequent pitch adjustments of no more than 1

o

at a time, assessing the difference in

flight performance each time.

Blade pitch adjustment

You may find your own method for adjusting the propeller blade pitch but the following method has

been found to work well.

Page 8 - 2

September 2001

Issue 4

Europa XS Rotax 914 Engine Manual

Summary of Contents for Rotax 914

Page 14: ...INTENTIONALLY BLANK Page 2 6 November 2007 Issue 10 Europa XS Rotax 914 Engine Manual ...

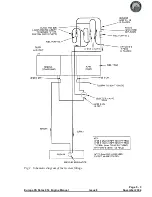

Page 28: ...Page 5 4 November 2004 Issue 8 Europa XS Rotax 914 Engine Manual Fig 2 Fuel system ...

Page 32: ...INTENTIONALLY BLANK Page 6 4 November 2004 Issue 8 Europa XS Rotax 914 Engine Manual ...

Page 40: ...INTENTIONALLY BLANK Page 8 6 September 2002 Issue 5 Europa XS Rotax 914 Engine Manual ...

Page 44: ...INTENTIONALLY BLANK Page 9 4 September 2002 Issue 5 Europa XS Rotax 914 Engine Manual ...