www.eurolube.com

EUROLUBE EQUIPMENT AB

PART NO 15715

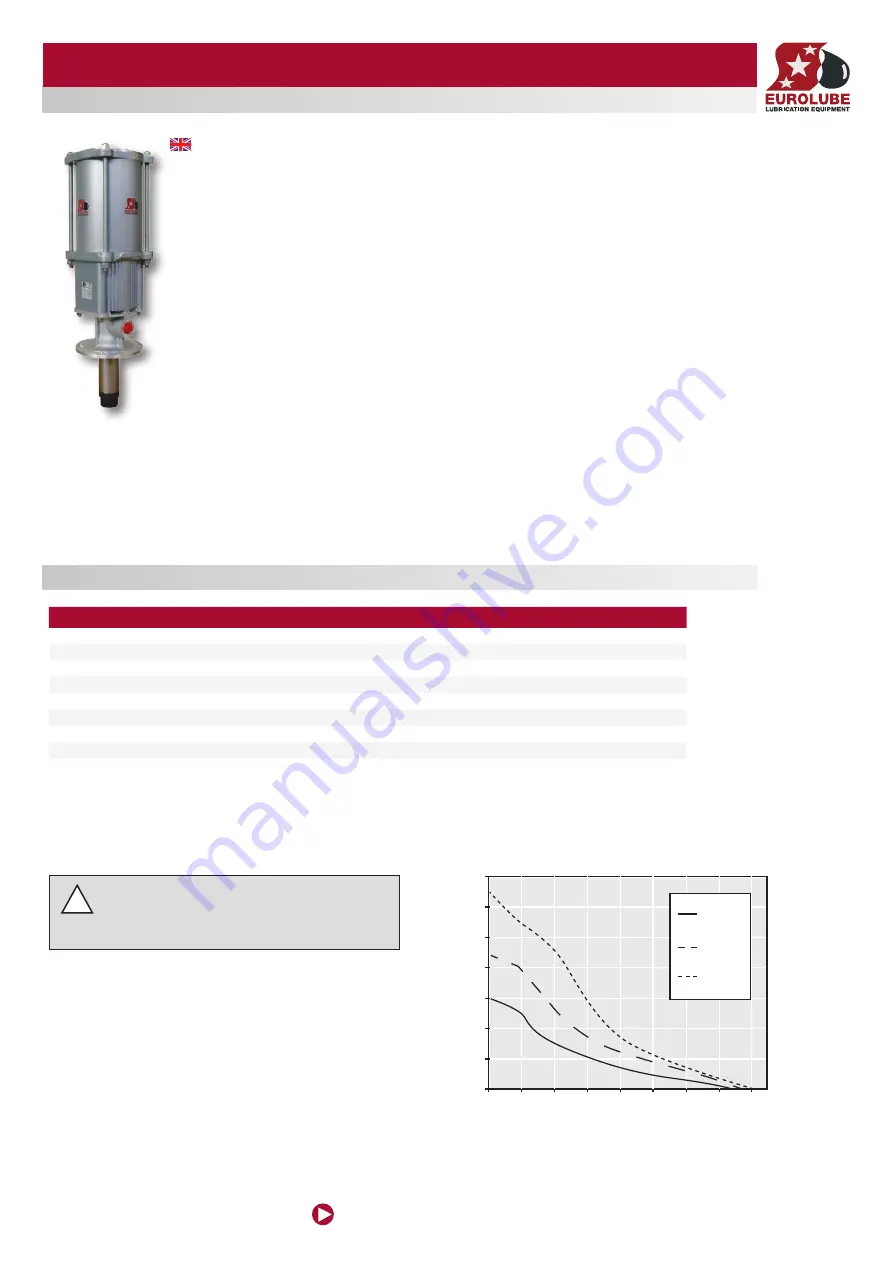

10:1 HV AIR OPERATED OIL PUMP

s

ER

V

Ic

E

g

U

ID

E

2

0

1

2

-0

8

O

R

Ig

INAL

MA

NU

AL

1

General

Thank you for choosing a high quality pump from Eurolube Equipment AB Sweden. The 10:1 oil pump features an unique air

motor for quiet and quick serviceability. Recommended for heavy duty units and large pipe installations. Please refer to the sales

catalogue for details on accessories. Or visit our website, www.eurolube.com.

The pump is suitable for simultaneous fluid distribution to multiple dispense points, or for pumping to distances of up to 90m

(300 ft).

The air motor features a precision air valve mechanism with dual valve ports for improved high speed breathing. It also contains a

positive trip detent spool mechanism that eliminates stalling (blowing air) by preventing the pump from stopping between strokes.

It has a simple yet durable construction with all internal parts lubricated at the factory using a life-tested synthetic grease.

The pumping assembly features a stainless pump rod for superior wear and corrosion resistance. The pump’s exterior is

constructed from aircraft grade extruded aluminum for an outstanding strength and reliability. The pump also has high quality

seals and is designed for long-term durability and ease of service. The pump is also equipped with internal pressure relief to

protect the system from thermal expansion.

A pump’s ability to deliver grease is based on the pressure (bar/psi) and quantity of air supplied to the air- motor and the amount of

material discharge (back) pressure to be overcome within the system.

WarninG!

Do NOT use solvents or other explosive fluids. An explosion can result in the pump when aluminium and zink parts

come in contacts with certain solvents. Never point a control valve at any portion of your body or another person. Accidential

discharge of pressure and/or material can result in injury. Read these instruction carefully before installation, operation or service.

DO nOT EXCEED MaXiUMUM PrESSUrE

PART NO

15715

Pump ratio

10:1

Maximum air pressure

10bar (150psi)

Recommended air pressure

2,75-8,6bar (40-125 psi)

Minimum air pressure

0,7bar (10 psi)

Air motor effective piston diameter

107mm (4,2”)

Nominal pump stroke length

81,3mm (3,25”)

Pump cycles per liter (gallon) @ 7 bar air pressure

105 cpl (28 cpg)

Fluid stall pressure @ 10 bar air pressure

110bar (1300 psi)

Approx air consumption @ 7 bar air pressure, 15l/min

1300 l/min (46 SCFM)

TEcHNIcAL DATA / TEKNIsKA DATA

NOTE:

This pump has been tested and found con-

forming to OSHA operating noise limits when used for

intended purpose (oil or coolant dispensing, intermit-

tent duty cycles).

!

Operating Noise Level

85 DbA @ 7 bar (100 psi) air and 11l/min (3 GPM)

0

0

7.6

(2)

15.1

(4)

22.7

(6)

30.3

(8)

37.9

(10)

45.4

(12)

53

(14)

60.6

(16)

13.7

(200)

27.6

(400)

41.4

(600)

55.1

(800)

68.9

(1000)

82.7

(1200)

96.5

(1400)

Pump Pressure/Flow

Test fl uid: 10W30 Oil

Fluid Pressure, bar

(psi)

Flow, l/min

(GPM)

5 bar

(70 psi)

7 bar

(100 psi)

10 bar

(150 psi)