Pellet store

Ventilation

65

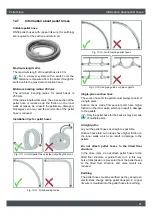

Example for ventilating the pellet store

Fig. 12-18: Filling nozzle in open air

1

ventilated sealing caps

If the filling nozzles lead inside a building, a

separate air line is to be set up from the pellet

store into the open. This must be designed so that no

dust escapes during filling and also no water can

penetrate from outside into the pellet store.

Fig. 12-19: Filling nozzle inside building

1

Sealed, unventilated sealing cover

2

Ventilation opening outside

Even if the filling nozzles protrude into a room in which

ventilation is available, ÖNORM M 7137 recommends

using only sealed, unventilated sealing covers.

Fig. 12-20: Filling nozzles in the boiler room

1

Ventilating the room

2

Sealed, unventilated sealing cover

3

Ventilation opening outside

If the pellets are stored in a bag that positioned in the

same room as the boiler, ventilation must be available

in this room. Operation of the boiler with external air

supply (as long as this is supported) is then not

possible.

Fig. 12-21: Bag in boiler room

1

Ventilating the room

2

Bag

3

Filling nozzle

Summary of Contents for PelletsCompact

Page 1: ...2020 07 21 EN 0000000061 V 022 1513 93003 003 PelletsUnit 7 15 kW Installation ...

Page 41: ...Installation Network connection 41 ...

Page 45: ...Electrical connections Overview of circuit boards 45 ...

Page 49: ...Electrical connections PE C4 circuit board 49 ...

Page 66: ...www eta co at ...

Page 67: ......

Page 68: ...www eta co at www eta co at downloads DOWNLOAD ...