Pellet store

Filling nozzles

57

Only in exceptional cases - when no narrow wall

of the pellet store is accessible from the outside -

can the filling nozzles be positioned on the longer wall.

Each half of the room needs its own nozzle with an

impact protection mat on the opposite side. The disad-

vantage is that halfway through the filling process, the

hoses must be exchanged.

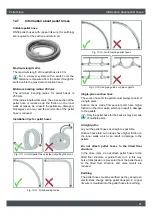

Fig. 12-3: Filling nozzles on the longer side

1

Two impact protection mats

2

Filling nozzle

3

Return air nozzle

4

Filling nozzle

Anchoring the filling nozzles

The filling nozzles must be firmly anchored in the wall

so they can withstand the movements of the hoses

from the delivery vehicle and cannot rotate when the

hoses are attached. Mount the filling nozzles horizon-

tally 200 mm under the ceiling of the pellet store so that

the pellets are not blown against the ceiling.

To install the filling nozzles in smooth holes or sewer

pipe cut-outs so they cannot twist, the ETA filling

nozzles are equipped with a flange that transfers the

forces directly into the wall via 4 screws.

ETA filling nozzles with 100 mm diameter fit exactly in

the cut-outs made for fitting a sewer pipe with 110 mm

outside diameter. The small gap between nozzle and

wall can be sealed with silicone; for larger gaps, foam

is used.

Fig. 12-4: Filling nozzle

If the filling nozzles are installed below ground in an

area, ensure that the hose can be led out of the area in

a straight line. Angled filling nozzles are available for

this situation.

Fig. 12-5: Angled filling nozzle

If an extension of the fill line is required, keep it as

short as possible to prevent friction loss while

filling.

The lever for tightening the coupling, around

300 mm long, needs a working range of 120°.

Summary of Contents for PelletsCompact

Page 1: ...2020 07 21 EN 0000000061 V 022 1513 93003 003 PelletsUnit 7 15 kW Installation ...

Page 41: ...Installation Network connection 41 ...

Page 45: ...Electrical connections Overview of circuit boards 45 ...

Page 49: ...Electrical connections PE C4 circuit board 49 ...

Page 66: ...www eta co at ...

Page 67: ......

Page 68: ...www eta co at www eta co at downloads DOWNLOAD ...