6.

• It is necessary to grease shafts and rollers annually .

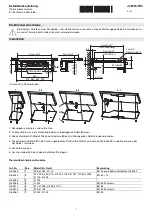

1 . Take off the protective covers, the slanted wall, the springs and the dough scrapers .

2 . Unscrew the fixing screws and take off the back panel first (A) followed by the stands

(B and C) .

3 . Take off the rollers (D, E, F, and G) and then joints (H, I, L and M) .

4 . Clean all the machine parts carefully using a damp sponge or cloth .

5 . Reassemble everything in this order: first the joints and rollers, then the stands and

back panel, then the dough scrapers, spring, slanted wall, and lastly the protective covers .

MAINTENANCE

TROUBLESHOOTING

LUBRICATING SHAFTS & ROLLERS

Issue

Cause

Solution

The machine won’t start

The machine is not plugged in or

connected to a source of power

Check the general switch, the plug,

and the feeding cable

The voltage input is incorrect

Use the proper voltage

There is another issue with the

machine

Stop using the machine immediately

and contact the manufacturer for

assistance

The machine causes an

electric shock

Wires are touching the structure of

the machine

Check the wires, confirming that

they are not touching the structure

of the machine

Only one set of rollers

is working

The belt is broken

Change the belt

The worm wheel is worn out

Change the worm wheel