SECTION 4

MAINTENANCE

PT-19XL PLASMARC CUTTING TORCH

D. Insert the nozzle into the torch.

E. Screw retaining cup onto the torch slowly to

HAND TIGHTNESS. The nozzle will seat

against the gas swirl baffle (P/N 948142). Do

NOT overtighten.

F. Screw heat shield onto nozzle. Do NOT over-

tighten.

4.3 REPLACING ELECTRODE AND GAS

SWIRL BAFFLE

A. Remove heat shield, retaining cup, and nozzle

as described above.

B. Remove electrode by using the 7/16-inch nut

driver (P/N 996568 - supplied with the torch).

If electrode holder did not come out with tip,

then remove it by using removal tool (P/N

999630) supplied with the torch. The lugs will

engage with the slots on the tip holder. Make

sure you hold the nut driver or removal tool

straight, whether removing or reassembling

the electrode, to avoid damaging the gas baffle.

The gas swirl baffle should come out with the

electrode holder. If it does not, remove by

using one finger.

C. Replace electrode if the hafnium insert is pit-

ted more than 0.090 inch.

8

4.1 INTRODUCTION

If this equipment does not operate properly, stop

work immediately and investigate the cause of the

malfunction. Maintenance work must be performed

by an experienced person, and electrical work by a

trained electrician. Do not permit untrained persons

to inspect, clean, or repair this equipment. Use

only recommended replacement parts.

NOTE

For detailed maintenance, troubleshooting, and parts

information on the power source, see Form F-14-483

(PCM-150) and supplement F-15-027 (PCM-1500), or

F-15-528 (PCM-8XL), F-15-108 (ESP-400), or F-15-

109 (ESP-600). F-15-141 (ESP-300). F-15-116 (ESP-

1000).

NOTE

Removing the nozzle from torch to check electrode

wear greatly reduces electrode life. To maximize

electrode life, only remove nozzle when changing

electrode.

4.2 REPLACING PT-19XL NOZZLE

(REFER TO FIGURE 5-1)

A. To remove nozzle, unscrew heat shield and

retaining cup, then grip the nozzle and pull

straight out.

NOTE

Always remove heat shield before removing retaining

cup. If heat shield will not loosen, tighten retaining cup

to reduce pressure on heat shield.

B. Check copper nozzle for melting from exces-

sive current, gouges from internal arcing, or

nicks and deep scratches on the O-ring seal-

ing surface. If any of these defects are visible,

replace the nozzle. (Discoloration of the inter-

nal surfaces and small black starting marks

are normal.) Hafnium particles may be re-

moved with fine sandpaper or steel wool.

C. Apply a light coating of silicone lubricant (P/N

17672-1 oz. tube) around the periphery of the

nozzle and O-ring. Make sure the O-ring (P/N

181W89) is set evenly around the shoulder of

the nozzle.

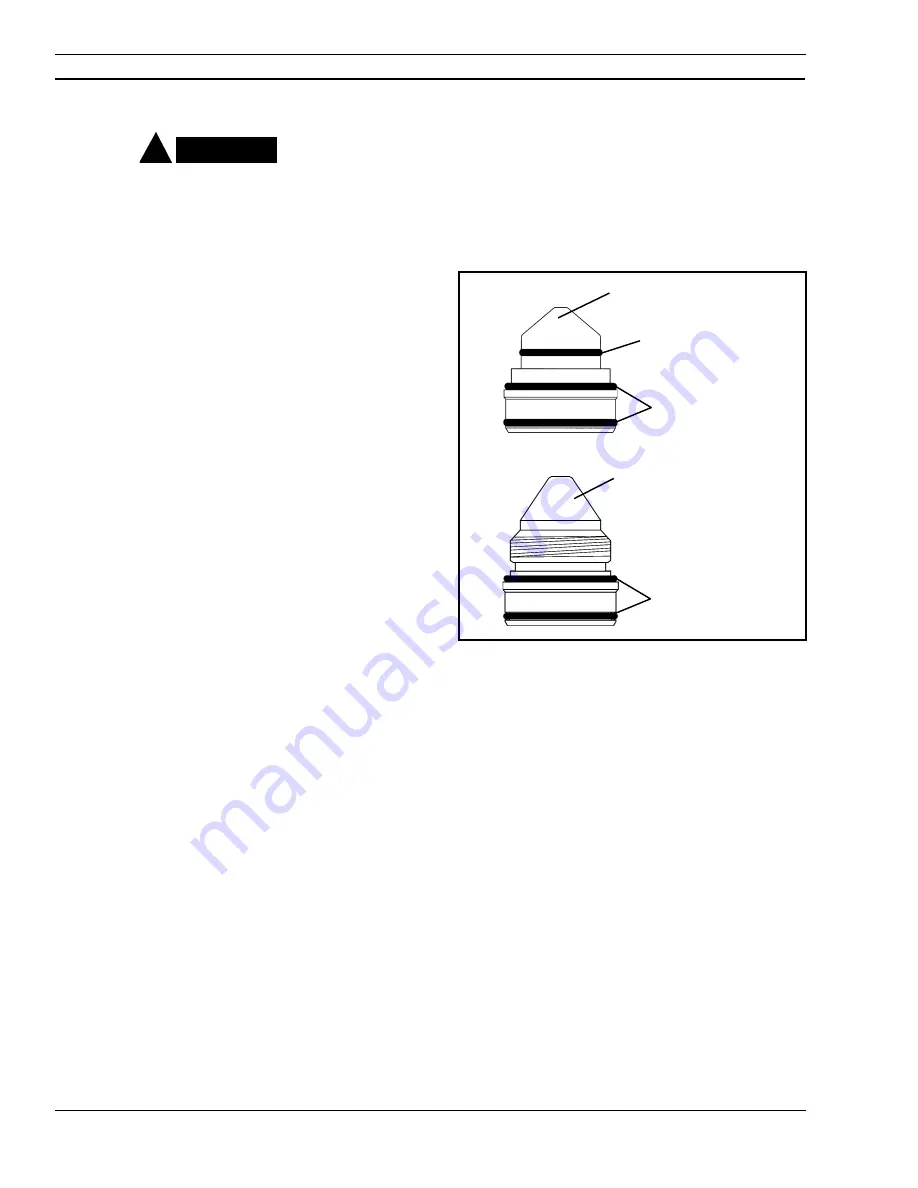

!

CAUTION

O-Ring - 994092

(2) O-Ring - 181W89

50 AMP NOZZLE - 34730

(2) O-Ring - 181W89

150 AMP NOZZLE - 21821

250 AMP NOZZLE - 21822

Figure 4-1. Proper O-Ring Position

(50,150 & 250A Nozzles)