PT-19XL PLASMARC CUTTING TORCH

SECTION 3

INSTALLATION AND OPERATION

5

3.1 INSTALLATION

To mount the PT-19XL torch, refer to F-12-528 (PCM-

8), F-14-493 (PCC-11), or F-15-116 (ESP-1000 Sys-

tem).

To use 4-1/2 ft. to 25 ft. torches with the PCC-11, holes

must be drilled in the PCC-11 sheetmetal opposite the

7/16-20 L.H. and 7/16-20 R.H. fittings on the brass

power block. These holes should be fitted with appro-

priate bushings.

Recommended hole size: 1.094" Dia.

Recommended snap bushing: P/N 639533

The "B" L.H. fitting should be plugged with:

"B" size plug (PCC-8 P/N 996857) and nut

"B" L.H. (P/N 10N40).

The "C" L.H. fitting should be plugged with:

"C" size plug (P/N 996856) and nut "C" L.H.

(P/N 10N18).

The existing 1.073" and 1.500" diameter holes should

be covered or plugged.

3.2 OPERATION

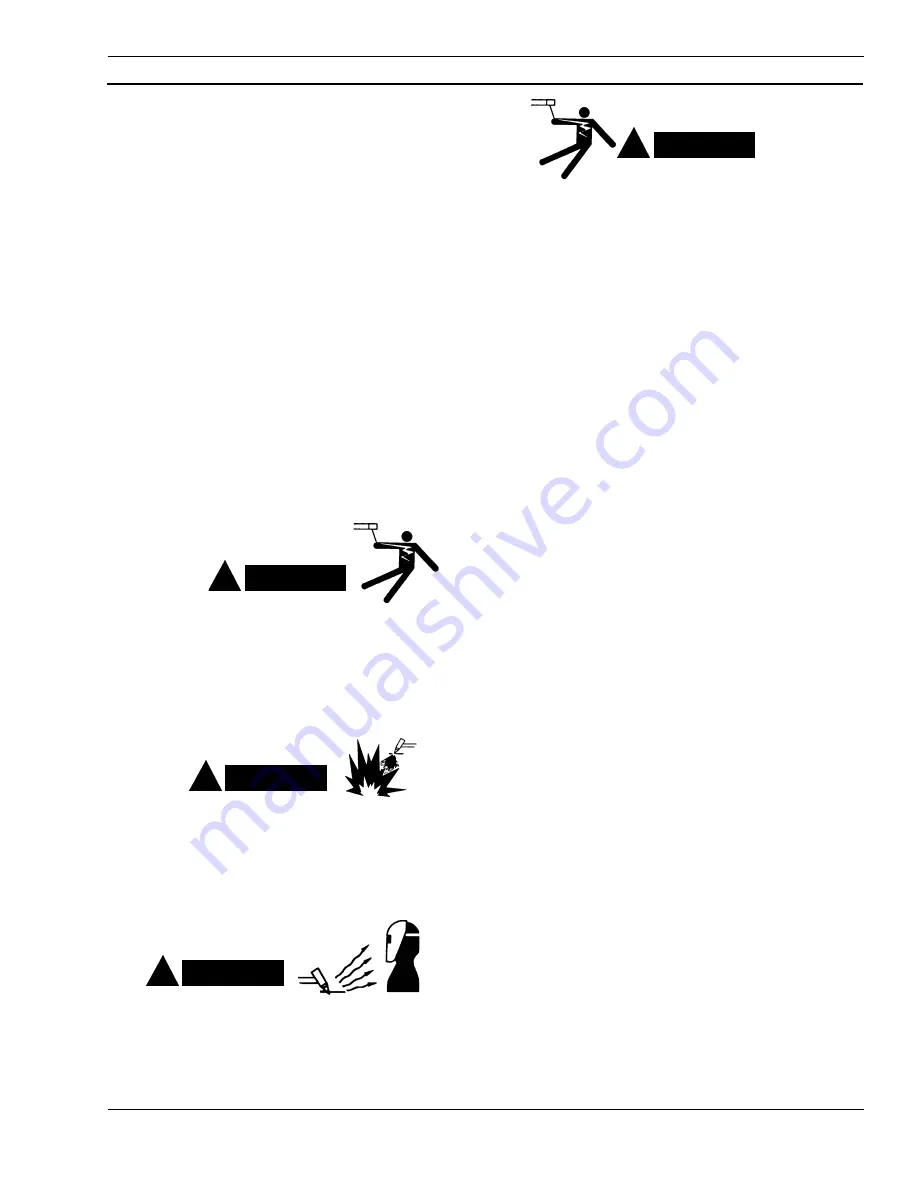

ELECTRIC SHOCK CAN KILL. Precautionary mea-

sures should be taken to provide maximum protec-

tion against electric shock. Therefore, before mak-

ing any adjustments or performing any mainte-

nance on the torch, make sure the power to the

torch is shut off.

Never use oil or grease on this torch. Handle parts

only with clean hands on a clean surface. Oil and

grease are easily ignited and burn violently in the

presence of oxygen under pressure. Use silicone

lubricant only where directed.

Wear the usual protective gloves, clothing, and

helmet. Helmet with filter lens shade No. 6 or 7

should provide adequate protection for your eyes.

!

DANGER

NOTE

!

WARNING

!

WARNING

!

WARNING

D. If cutting arc is lost during a cut, the pilot arc will

immediately reignite as long as the switch is

depressed. You then have about 6 seconds to

move the torch close enough to work to rees-

tablish the cutting arc.

E. The cutting arc will extinguish at the end of the

cut; however, the start switch should be re-

leased to keep the pilot arc from reigniting.

Never touch any torch front end parts (Nozzle,

Retaining Cup, Etc.) unless the power switch is in

the off position, and primary power is shut off at the

disconnect.

A. Position the torch over the edge of the

workpiece with the tip of the nozzle set at about

3/8" above workpiece (standoff).

If piercing thick plate, increase standoff to 1/2" for up to

1/2" thick plate, 3/4" for thicker plate. Then return to

3/8" standoff after completing the pierce and you are

ready to cut.

B. Lower your protective helmet and activate

start switch. Pilot arc and high frequency will

energize and gas will start flowing. The pilot

arc should then transfer to the cutting arc.

NOTE

If cutting arc does not start within 6 seconds, the pilot

arc will shut off. Deactivate start switch. Check to be

sure gas pressures are adequate, work cable is firmly

connected to workpiece, cooling water is on, standoff

is about 3/8", etc. Then start from step one again.

C. Maintain the standoff of 3/8" throughout the cut

and move the torch at a rate that produces the

desired cut quality. The cutting should pro-

duce a straight fine spray of molten metal

emitting from beneath the workpiece as illus-

trated in Figure 4-1. See Table 2-1 for recom-

mended cutting speed range.