-- 18 --

bt30d1ea

Note!

The mains cable areas and fuse sizes as shown above are in accordance with Swedish

regulations. Use the welding power source in accordance with the relevant national regulations.

Note!

The welding power source is designed for connection to a 230 / 400 volt

system with four conductors.

If the power source is to be used in countries with a higher supply voltage, the power

source must be connected via a safety transformer.

6

OPERATION

General safety regulations for the handling of the equipment can be found on

page

13

. Read through before you start using the equipment!

6.1

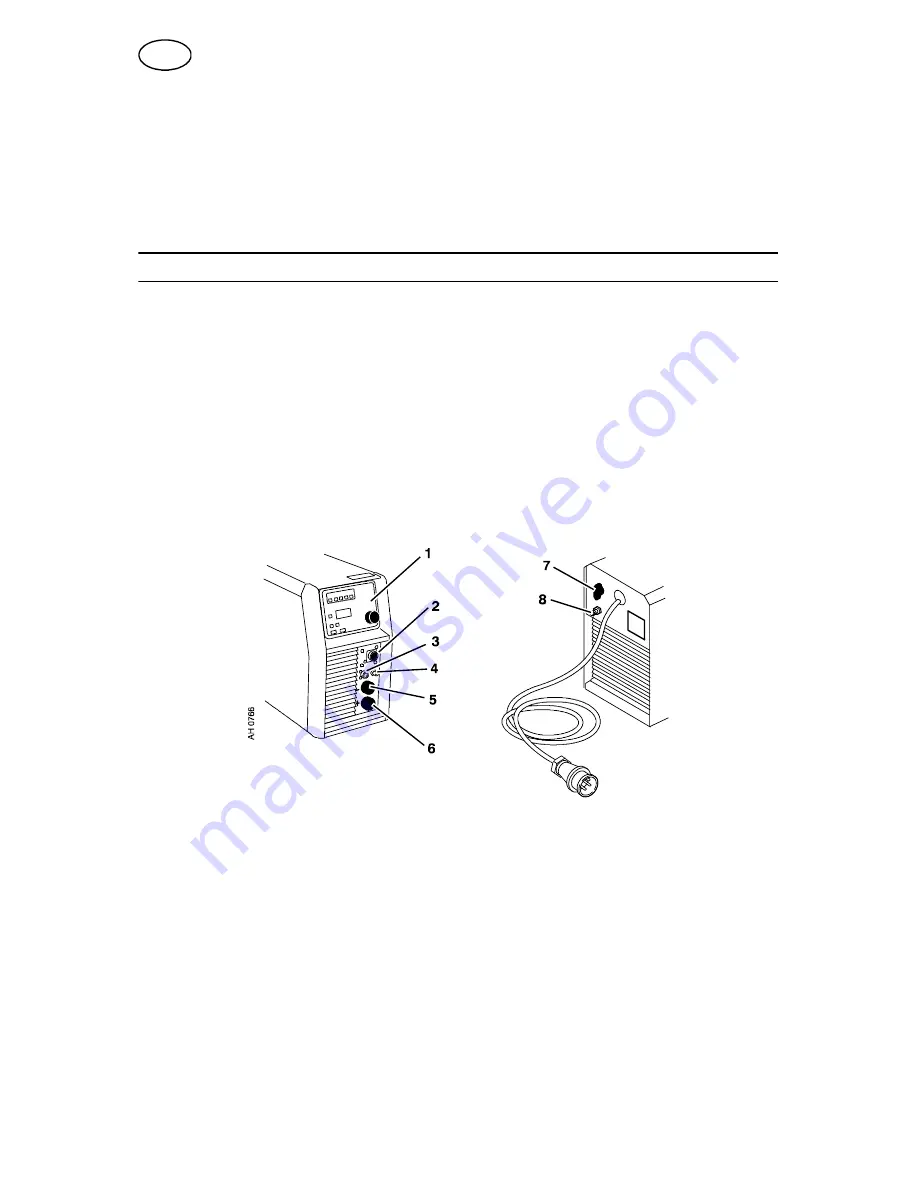

Connections and control devices

1

Control panel,

see separate instruction manual

5

Connection for welding cable (--) or

welding torch

2

CAN connection for cooling unit or remote

control unit

6

Connection for return cable (+)

3

Connection for start signal from the

welding torch

7

Mains voltage switch

4

Connection for gas to the torch

8

Connection for shielding gas

6.2

Fan control

The power source has a time control that means that the fans continue to run for 6.5

minutes after welding has stopped, and the unit switches to energy--saving mode.

The fans start again when welding restarts.

The fans run at reduced speed for welding currents up to 110 A, and at full speed for

higher currents.

6.3

Overheating protection

The welding power source has overheating protection that operates if the

temperature becomes too high. When this occurs the welding current is interrupted

and a fault code is displayed on the control panel.

The overheating protection resets automatically when the temperature has fallen.

GB

Summary of Contents for Origo Tig 3000i

Page 21: ... 21 p ...

Page 22: ...Edition 100114 Diagram Ñõåìà 22 cc19e ...

Page 23: ...Edition 100114 23 cc19e ...

Page 27: ... 27 p ...

Page 28: ... 28 backpage ...