Edition 080529

-- 32 --

1sC1425

SERVICE INSTRUCTIONS

What is ESD?

A sudden transfer or discharge of static electricity from one object to another. ESD stands for

Electrostatic Discharge.

How does ESD damage occur?

ESD can cause damage to sensitive electrical components, but is not dangerous to people.

ESD damage occurs when an ungrounded person or object with a static charge comes into

contact with a component or assembly that is grounded. A rapid discharge can occur,

causing damage. This damage can take the form of immediate failure, but it is more likely

that system performance will be affected and the component will fail prematurely.

How do we prevent ESD damage?

ESD damage can be prevented by awareness. If static electricity is prevented from building

up on you or on anything at your work station, then there cannot be any static discharges.

Nonconductive materials (e.g. fabrics), or insulators (e.g. plastics) generate and hold static

charge, so you should not bring unnecessary nonconductive items into the work area.

It is obviously difficult to avoid all such items, so various means are used to drain off any

static discharge from persons to prevent the risk of ESD damage. This is done by simple

devices: wrist straps, connected to ground, and conductive shoes.

Work surfaces, carts and containers must be conductive and grounded, use only antistatic

packaging materials. Overall, handling of ESD--sensitive devices should be minimized to

prevent damage.

WARNING !

STATIC ELECTRICITY can damage circuit

boards and electronic components.

SSSS

Observe precautions for handling electrostatic

sensitive devices.

SSSS

Use proper static--proof bags and boxes.

ESD

Thermal switch (thermostat) replacement procedure

1.

Spare thermostat must be the same type as replaced one.

2.

Spare thermostat should be mounted within radius of 10mm or less from broken

thermostat. If it’s possible and safe for transformer/inductor winding, broken thermostat

may be removed. Then the spare thermostat is to be mounted right in place of broken

one.

3.

Spare thermostat should adjoin protected winding as tight as possible.

4.

Spare thermostat must be secured with silicone glue of working temperature of 200

o

C

or higher.

Summary of Contents for Origo Mag C171

Page 8: ...Edition 080529 8 1sC1425 Mig C141 ...

Page 9: ...Edition 080529 9 1sC1425 Mig C151 ...

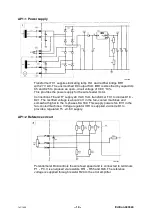

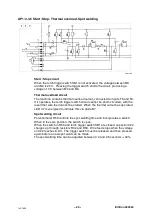

Page 10: ...Edition 080529 10 1sC1425 DESCRIPTION OF OPERATION AP1 Control board clka0e02 ...

Page 12: ...Edition 080529 12 1sC1425 AP1 Mig C141 C151 component positions clka0e03 ...

Page 15: ...Edition 080529 15 1sC1425 Mag C171 ...

Page 16: ...Edition 080529 16 1sC1425 Mag C201 ...

Page 17: ...Edition 080529 17 1sC1425 DESCRIPTION OF OPERATION AP1 Control board clka1e03 ...

Page 18: ...Edition 080529 18 1sC1425 clka1e04 ...

Page 23: ...Edition 080529 23 1sC1425 AP1 Mag C171 C201 component positions clka1e05 ...

Page 26: ...Edition 080529 26 1sC1425 Mag C251 ...

Page 31: ...Edition 080529 clkb0e13 31 1sC1425 AP1 Mag C251 component positions ...

Page 36: ...Edition 080529 36 2sC1425 OrigoTM Mig C151 1 3 2 ...

Page 37: ...Edition 080529 37 2sC1425 OrigoTM Mag C171 C201 C251 1 3 2 Electrical installation ...

Page 43: ... 43 notes NOTES ...

Page 44: ... 44 notes ...